2024.09.24

Series

Series

Through the previous posts of “SK Innovation’s ESG management” series, we have introduced why it is important for us to understand and integrate ESG management in our performance. This time, let us get to know how SK Innovation and its subsidiaries have been preparing for ESG management up to date.

01 | Global war on plastic waste

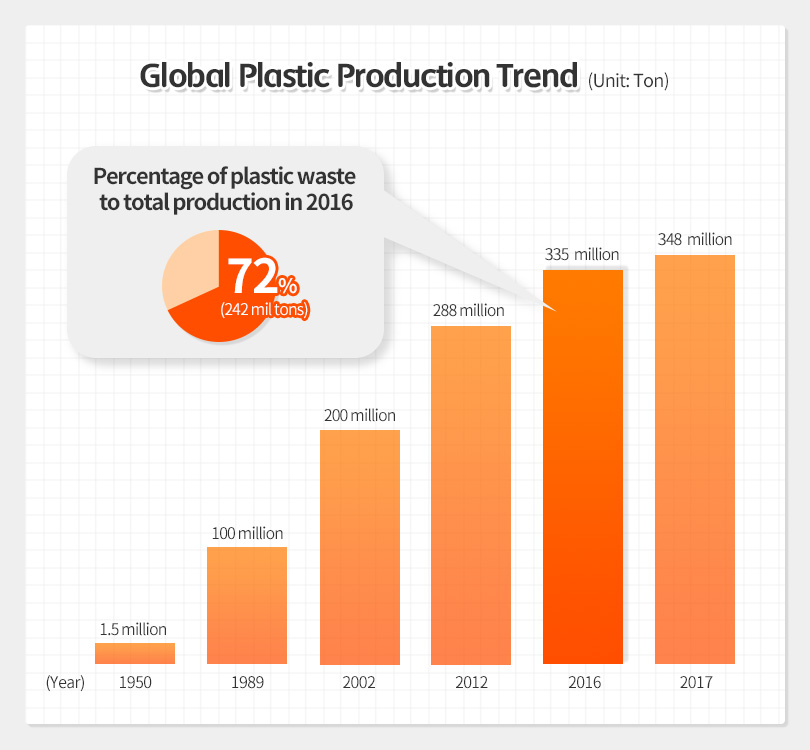

According to “A Study on Plastic Management Strategies for Transition to a Circular Economy,” a research report published by the Korea Environmental Institute (KEI) at the end of last year, the global plastic production amounted to 348 million tons in 2017, and the plastic waste produced from 2016 was about 242 million tons, accounting for 72% of the total plastic production. Plastics have a wide range of applications from consumer goods to industrial goods, so the production volume has been increasing inevitably. Moreover, as the delivery business becomes more active due to the COVID-19 crisis and people use more disposable containers, plastic waste has been surging globally.

▲ Source: “A Study on Plastic Management Strategies for Transition to a Circular Economy” published by the Korea Environmental Institute (KEI) on December 31st 2019

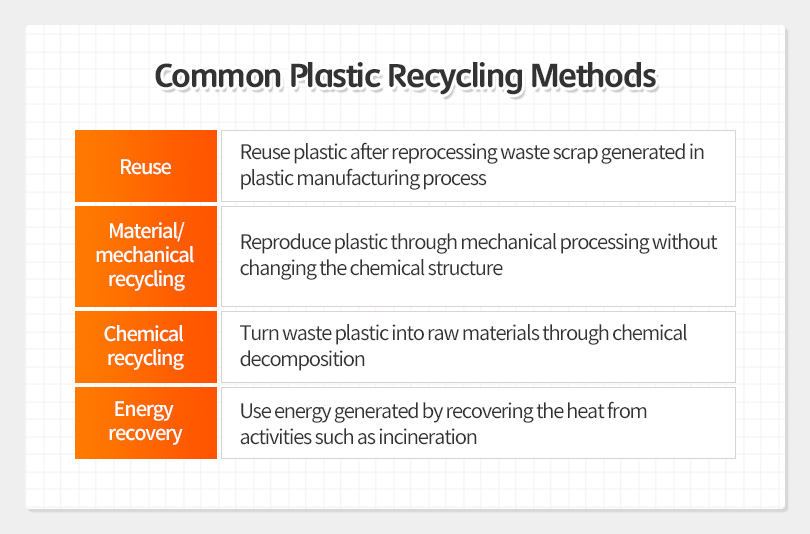

How to use and dispose the plastic well is important, but another effective shortcut to reducing waste plastic is to increase the recycling rate. For this, breakthrough and fundamental improvements are needed in the production stage. This is why the movements of companies that produce plastics are critical.

02 | Chemical products made from plastic waste

The incredible transformation of waste plastic started at the SK Innovation Environmental Science and Technology Institute (formerly SK Innovation Institute for Technology Innovation), located in Daejeon, South Korea. Park Jae-young, senior researcher of the R&D Innovation Promotion Department, said, “What made this possible is the pyrolysis technology for oil production that is being implemented with SK Global Chemical.” “If the utilization of pyrolysis oil is increased, it may be possible to solve a lot of environmental problems such as a plastic island – a recent issue,” she added.

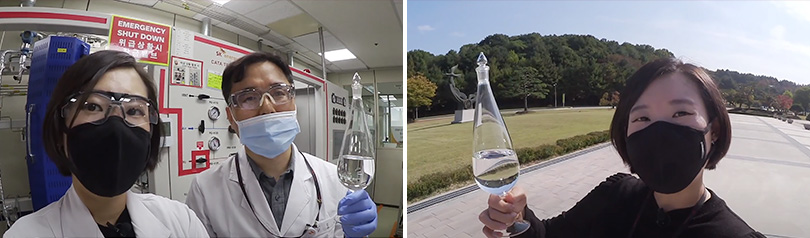

▲ Park Jae-young (female staff), senior researcher of the R&D Innovation Promotion Office hold the prototype of a solvent made from pyrolysis oil

Pyrolysis technology for oil production is a reverse implementation of conventional plastics and vinyl manufacturing technology. It refers to petrochemical raw materials’ production by heating and decomposing waste plastics and waste vinyl at 300 to 500°C under oxygen-free conditions.

Regarding the reason SK Global Chemical has been researching pyrolysis technology for oil production, Lee Jong-hyuk, senior manager of SK Global Chemical’s SV-based BM innovation Squad said, “As part of our ESG management, SK Global Chemical aims to build a resource circular economy through pyrolysis after collecting plastic waste. As this becomes commercialized, it will change into a DBL1 model that can create economic value as well.”

(1) DBL (Double Bottom Line): the management strategy of pursuing both economic and social values at the same time

Material recycling is challenging to recycle due to technical limitations such as physical properties of plastic and pollution. Thus it is necessary to develop chemical technologies using pyrolysis oil or the like to increase the recycling rate of plastic waste. Accordingly, SK Innovation and SK Global Chemical have succeeded in creating eco-friendly solvents and lubricant base oil prototypes by removing impurities from pyrolysis oil extracted from waste plastics, using the know-how and R&D capabilities of petrochemical product processing accumulated for years.

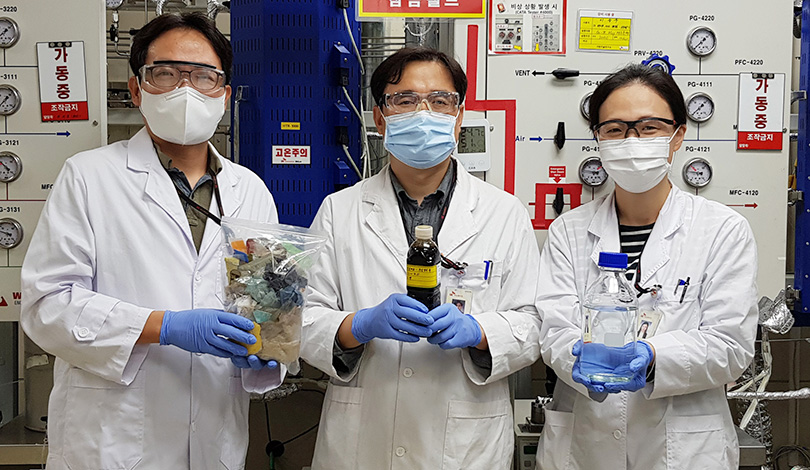

▲ Researchers at SK Innovation’s Environmental Science and Technology Institute are holding recycled raw materials made from waste plastic, pyrolysis oil, and a prototype of solvent made from pyrolysis oil (in order from left to right)

However, it was not easy to achieve this success. Management of impurities that cause chemical reactions is particularly important in order to make decomposed oil into high-quality chemicals again. In addition, it is difficult to produce chemical products of uniform quality because waste plastics are made of various materials such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), which are later discharged indiscriminately, and there are many products made from composite materials.

Regarding this, Park Jae-young said, “We have thought about whether there is anything that could differentiate it from existing products by utilizing the characteristics of waste plastic while maintaining the performance of the existing ones.” “By utilizing accumulated catalyst and process technologies, we developed a technique to remove impurities specialized for waste plastics. We also got feedback from customers that odor was improved compared to existing products,” he continued.

The pyrolysis oil prototype recently introduced by SK Innovation features a significantly reduced impurities compared to existing products. The solvent, one of the prototypes, has a high paraffin content and a low odor, and the lubricant base oil is also found to be suitable for making the highest grade base oil of Group III+. Besides, SK Innovation has also applied for a patent related to the manufacturing of pyrolysis oil with the technology to reduce impurities specialized for waste plastic in Korea.

Earlier, in July 2019, SK Innovation signed an MOU with Jeju Clean Energy, which has excellent pyrolysis technology. Jeju Clean Energy is registered as a member of Korea Resource Circulation Service Agency (KORA) under the Korea Environment Corporation of Ministry of Environment, and has been operating a pyrolysis factory in Jeju Island since 2013.

▲ Jeju Clean Energy produces pyrolysis oil from waste plastic and waste vinyl

Regarding this cooperation, Park commented “Recently, there have some companies stopped producing pyrolysis oil because it is hard to secure a distributor.” He add, “We expect to contribute to solving environmental problems through the production of high-quality pyrolysis oil, and to create a win-win model through technology sharing with small and medium-sized enterprises like Jeju Clean Energy.”

03 | Keep making efforts to achieve Green Balance 2030

This transformation of waste plastic into chemical products was possible thanks to the practical methodology of SK Innovation’s ESG management strategy, Green Balance 2030. However, still there is a long way to achieve Green Balance 2030. Under the Korean Petroleum and Petroleum Alternative Fuel Business Act (hereafter “Petroleum & Alternative Act”, SK Innovation can only use petroleum and petroleum products as raw materials, so pyrolysis oil produced using waste plastic cannot be refined for commercial purposes.

In addition, under the Waste Management Act, the use of waste plastic pyrolysis oil is restricted so that it can be used only as an industrial energy source, such as fuel for power generation. In other words, pyrolysis oil is currently available for commercial sale only as fuel oil, and cannot be sold as other petrochemical products.

To solve this problem, SK Innovation is proposing to the Ministry of Trade, Industry and Energy and the Ministry of Environment to include pyrolysis oil in petroleum and petroleum products under the Petroleum & Alternative Act, and to establish a new clause related to pyrolysis oil in the recyclable type under the Waste Management Act.

▲ (Left photo) Lee Ho-won, a principal researcher at Catalyst Platform Division of SK Innovation holds The prototype of a solvent made from pyrolysis oil introduced by Lee Ho-won, principal researcher at Catalyst Platform Division of SK Innovation (left) and by another researcher at SK Innovation Institute of Environmental Science and Technology (right).

Leader of this project, Cho Sang-hyun, a senior manager at Technology Strategy Office of SK Innovation, revealed, “It is not easy to make chemical products from waste plastics. This is the result of collaboration among various organizations within SK Innovation Environmental Science and Technology Institute.” “In the future, our institute plans to continue research to produce a variety of eco-friendly and high-functional products so that we can create a virtuous cycle structure that actively solves environmental problems by expanding our portfolio of various recycled products with raw materials obtained from waste resources,” he added.

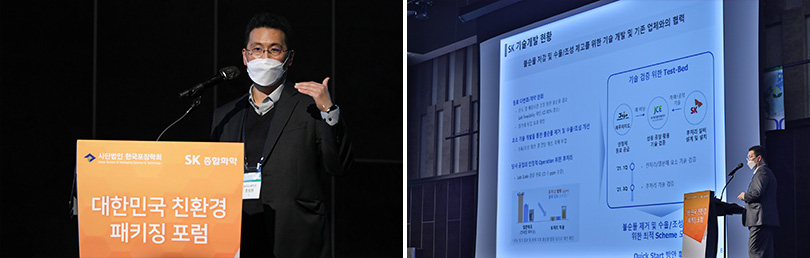

▲ Cho Sang-hyun gave a presentation during the 2020 Korea Eco-friendly Packaging Forum held on November 18th in Seoul, Korea

Cho Sang-hyun also expressed his ambition, “Starting from next year, we will take on the challenge of producing plastic raw materials through pyrolysis oil based on our accumulated technology with SK Innovation affiliates.”

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin