SK Geo Centric

SK Geo Centric

▲ Mike Otworth, CEO of PureCycle Technologies (left) posed for a photo with Na Kyung-soo, CEO of SK Geo Centric (right) at PureCycle Technologies’ facility in the U.S. during SKGC’s North American tour in November 2021.

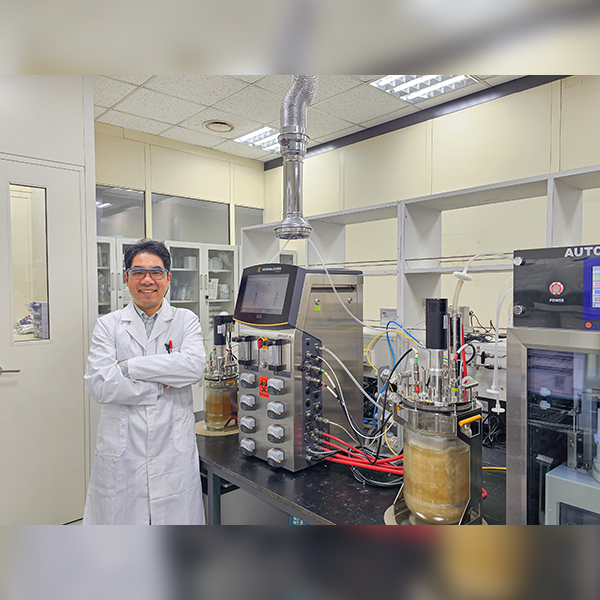

SK Geo Centric (SKGC) is presenting a plan for the circular plastic ecosystem, taking the lead in providing a fundamental solution to the problem of plastic wastes. In November of last year, the top management of SKGC visited three partnering enterprises in North America to accelerate its mission to seize three major technologies for chemical recycling, knuckling down to its global moves.

In the second episode of this series, where we can follow the leaders of SKGC to meet its global partners, let’s visit at PureCycle Technologies, a U.S. advanced recycling company.

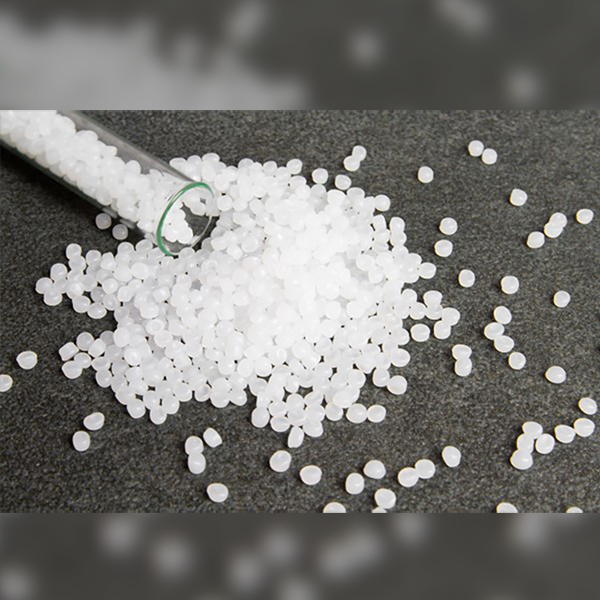

PureCycle Technologies, founded in 2015, extracts ultra-pure recycled (UPR) polypropylene (PP), the most commonly used main material of plastic, from plastic waste. So far, PureCycle Technologies is the only company in the world that has developed chemical recycling technology to generate URP PP from plastic waste by eliminating impurities, odors, and colors by using a solvent.

▲ (From left) Waste plastic trash, finely crushed waste plastic trash, (Biaxially Oriented Polypropylene (BOPP) film, ultra-pure recycled PP obtained by using a solvent.

PP accounts for around 25% of total plastic demand and is widely used in a variety of products such as automotive interior materials, electrical equipment, food containers, toys, household essentials, and others in a variety of colors and forms. Unlike PET, which is utilized as a single material, PP is typically employed by combining different materials and additives to achieve the desired properties. As a result, current physical recycling technology makes it difficult to remove the scent, color, and foreign substances from PP, thereby it is recycled for a limited purpose, and the majority of it is burned or landfilled, causing environmental pollution.

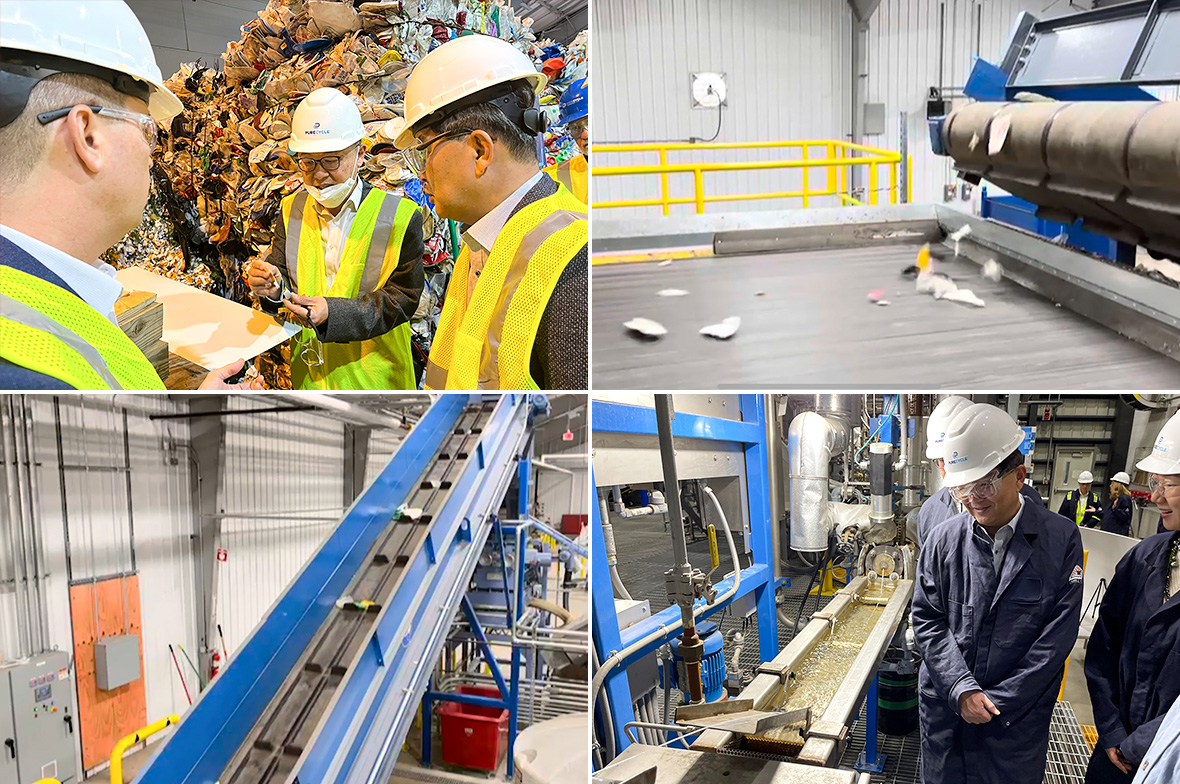

▲ (Top left) Na Kyung-soo, CEO of SKGC (first from the right) examines plastic wastes used as ingredients for ultra-pure recycled PP./ (Top right) Plastic trash is transferred to the pre-process stage of PureCycle Technologies / (Left center) The process by which waste plastics are separated in conveyer belts to produce ultra-pure recycled PP/ (Right center) Na Kyung-soo, CEO of SKGC, monitors the plastic cleaning process in order to produce ultra-pure recycled PP / (Bottom) Na Kyung-soo, CEO of SKGC checks an ultra-pure recycled PP.

Plastic trash from daily life is converted into new recycled resins using PureCycle Technologies’ chemical recycling technology, which requires a pre-processing stage to remove impurities. Daily plastics are sorted in conveyors and delivered to the main facility for extraction of UPR PP after cleaning in PureCycle Technologies’ pre-processing process.

▲(From left) A container filled with plastic waste (right) and one with crushed plastics (left), ultra-pure recycled PP created from waste plastics, and a plastic bottle made from ultra-pure recycled PP.

After checking the pre-processing step, the top management of SKGC went to PureCycle Technologies’ first facility located nearby. The construction of this facility is expected to finish by the end of 2022, and it will be capable of pre-processing around 70,000 tons of plastic trash and extracting approximately 50,000 tons of UPR PP. Furthermore, PureCycle Technologies plans to build a second facility in Augusta, Georgia, the U.S., which is expected to complete construction by late 2025, and is a large-scale operation with five lines that will be capable of treating around 300,000 tons of waste plastics.

▲ Na Kyung-soo, CEO of SKGC (third from right), and the top management of SKGC paid a visit to PureCycle Technologies in the U.S. in November 2021.

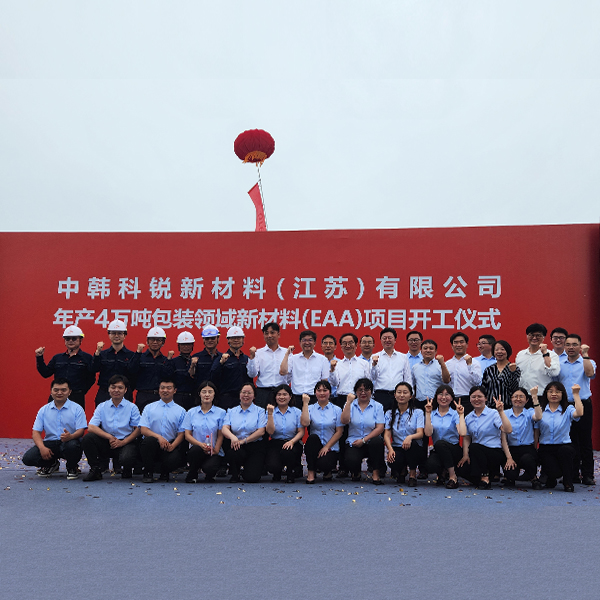

Previously, in August 2021, SKGC signed an MOU to establish a joint venture for recycling PP waste with PureCycle Technologies. Following that, the two also entered a Heads of Agreement (HOA) to build Asia’s first PP recycling plant in Ulsan, South Korea. The HOA ceremony took place at CES 2022, in which SK was participant, on January 6th (PST).

▲ (Left) Na Kyung-soo, CEO of SK Geo Centric, signed a Memorandum of Understanding (MOU) to form a JV with Mike Otworth, CEO of PureCycle Technologies via a video conference in August 2021 / (Right) SKGC signed a HOA with PureCycle Technologies to build the first PP recycling plant in Asia on January 6 (PST), at CES 2020 held in Las Vegas, the U.S. From left: CEO of PureCycle Technologies Mike Otworth (third), Vice Chairman & CEO of SK Innovation Kim Jun (fourth), Head of Green Business Group of SKGC Kang Dong-hoon.

The HOA signing ceremony was attended by executives from both companies, including Kim Jun, Vice Chairman & CEO of SK Innovation (mother company of SKGC), Mark Otworth, CEO of PureCycle Technologies, Kang Dong-hoon, Head of SKGC’s Green Business Group. After this HOA, the two companies will build Asia’s first recycled PP plant in Ulsan, South Korea this year. The estimated annual capacity of the facility is about 60,000 tons, and the construction is expected to end in late 2024. SK Geocentric will exclusively sell recycled PP produced at this plant in Korean market.

▲ CEO of PureCycle Technologies Mike Otworth (first from right) tests the plastic cup return machine that used reusable cups made from PureCycle’s ultra-pure recycled polypropylene.

After the HOA ceremony, the executives of the two companies tour around SK exhibition hall at CES 2022 together to explore the carbon reduction and Net Zero strategies. Here, they also tested the unmanned plastic cup return machine that applied SK Telecom’s AI technology and used reusable cups made of PureCycle’s UPR PP.

CEO of PureCycle Technologies, Mike Otworth, shared his thought after sigining the HOA with SKGC and visiting SK’s booth at CES 2022 on January 6 (PST) through a short interview below:

We hope the collaboration between SKGC and PureCycle Technologies will be successful, and hope the two companies will bring more meaningful projects to build a greener planet in the near future.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin