SK Geo Centric

SK Geo Centric

In April this year, SK Geo Centric (SKGC) announced the company’s cooperation with Kolon Industries to launch biodegradable plastic product PBAT (Polybuthylene Adipate-co-Terephthalate). As the launching is fast approaching, we have met Park Sang-hyun, the PO (Project Owner) of B1 Squad, SKGC to learn more about what PBAT is and how SKGC is taking Green Transformation through the development and commercialization of this eco-friendly product.

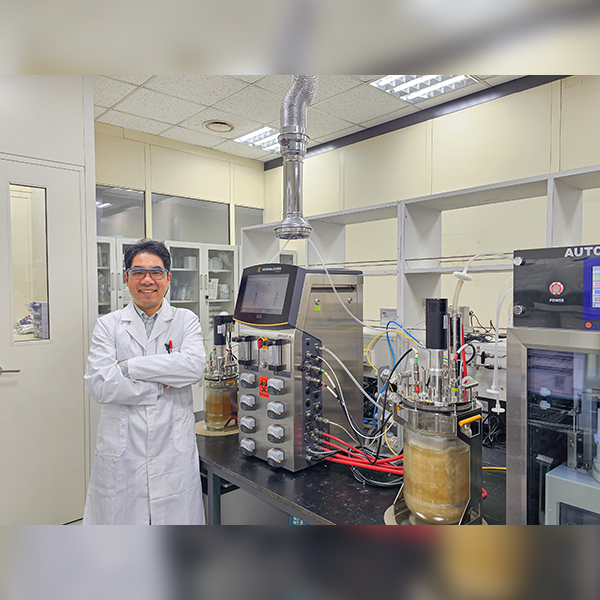

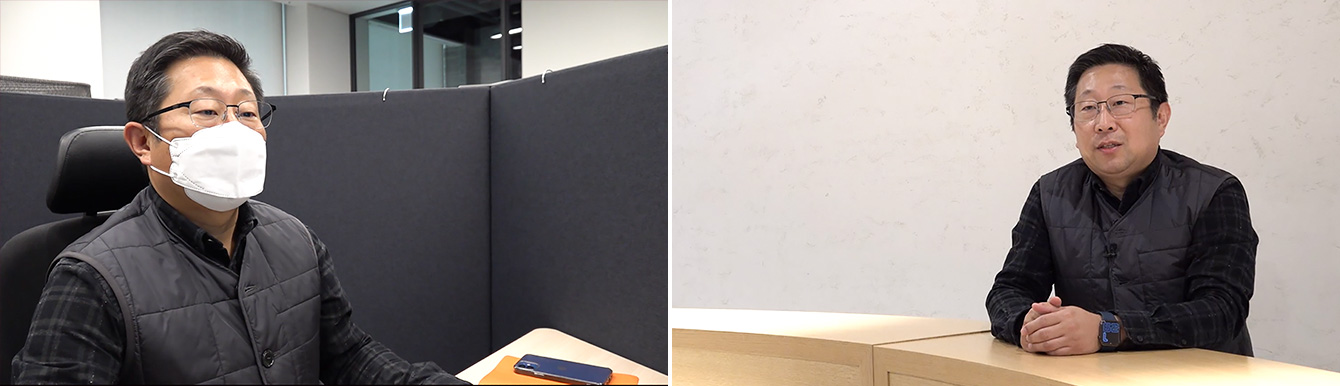

▲ Park Sang-hyun, PO of B1 Squad, SK Geo Centric

ㅣFirst of all, what is PBAT?

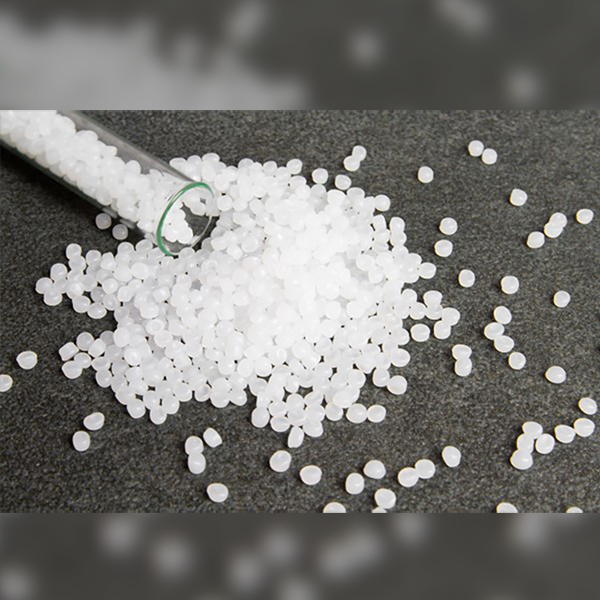

PBAT (Polybutylene Adipate-co-Terephthalate) is an eco-friendly plastic product that is decomposed by microorganisms in nature. It is known that general plastic products take nearly 100 years to decompose naturally, but PBAT products are known as highly eco-friendly plastics that decompose naturally within 6 months at a landfill.

▲ (Left) The biodegradable plastic PBAT / (Right) The biodegradable plastic bags used for SK innovation’s eco-friendly campaign Sanhaejinmi are made of PBAT produced by SKGC

ㅣWhy did SKGC jointly develop PBAT with Kolon Industries?

Kolon Industries has production know-hows in nylon and polyester products. Meanwhile, SKGC is the only in Korea that can produce 1,4-Butanediol, which has PBAT as the main material, and we own a large marketing network with various brand owners. Therefore, we can take full advantage of each company’s strengths to develop high-quality PBAT products togethere.

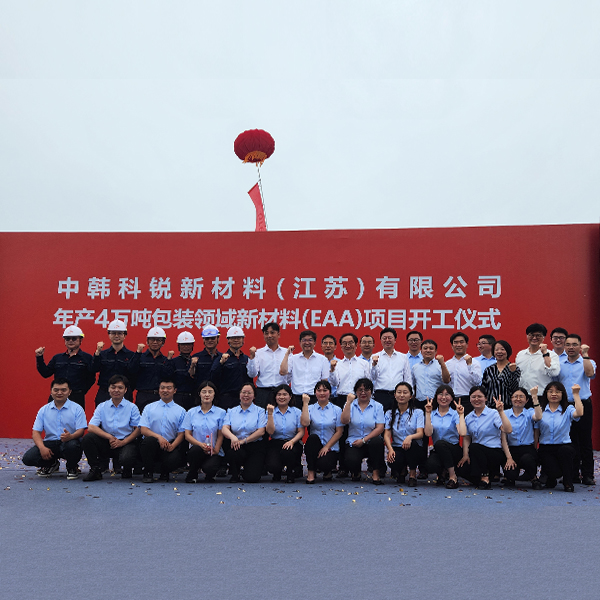

▲ CEO of SKGC Na Kyung-soo (left) and CEO of Kolon Industries Jang Hee-goo (right) show a sample of PBAT product jointly developed by the two companies after signing a strategic partnership to commercialize eco-friendly biodegradable plastic products at SK Building in Seoul on April 7th, 2021.

ㅣWe heard that the high-quality PBAT products are about to be officially launched soon. Can you tell us about the specific plan?

Yes, we are going to launch the PBAT Batch products that have been successfully developed through our collaboration with Kolon Industries over the past year soon. The production methods include batch polymerization and continuous polymerization. The former is preferred in small-scale production of various types of products, while the latter is better for large-scale production of a few types of products. Next year, we plan to commercialize the PBAT Batch products to develop their uses and find sales channels, and in parallel, we will start PBAT continuous polymerization business in full swing.

ㅣWhat are the expected outcomes of this project?

PBAT is an eco-friendly plastic product that can be used to produce agricultural vinyl, food packaging, and fishing nets, which are difficult to recycle. It is considered an effective solution to overcome the difficulties of recycling plastic wastes that are contaminated or mixed with other wastes. In particular, PBAT has the advantage of being naturally decomposed in general soil, so it is expected to have high utility.

In other words, we believe that PBAT, a biodegradable plastic, will be utilized more widely as a new technology that can compensate for the shortcomings of other recycling technologies.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin