SK Innovation

SK Innovation

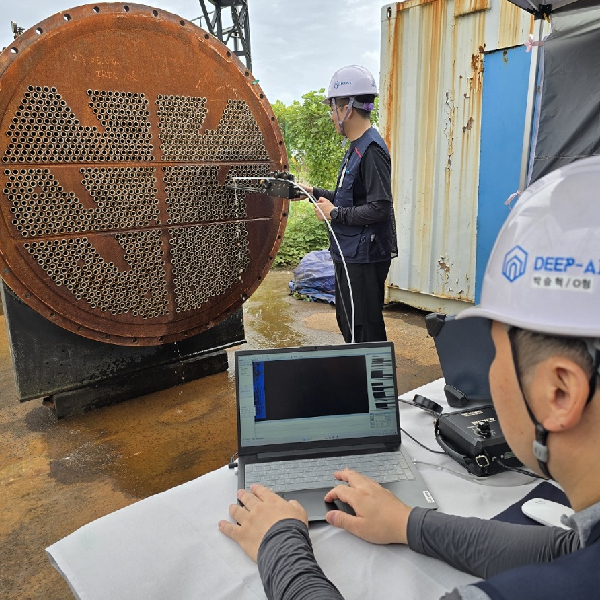

In the eighth episode of this series, we would like to introduce how SK Innovation Ulsan Complex (hereinafter “Ulsan CLX”) is taking Green Transformation through practicing Green maintenance work. Let’s meet Ok Jin-kyoo, Head of Machinery·Equipment Office, and Hwang Sun-jae, Head of Instrument-Electricity Office, who are both in the Facility Division of SK Energy, to learn the details of this story.

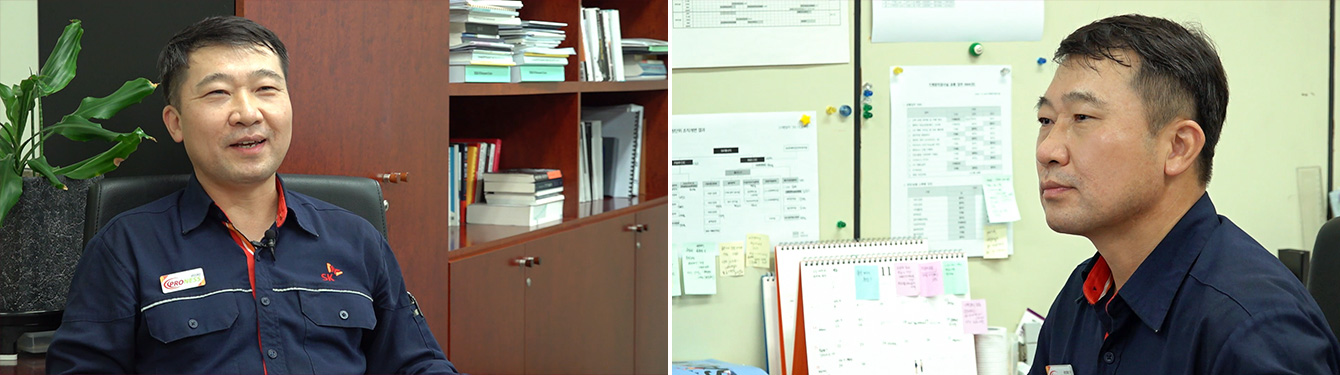

▲ Ok Jin-kyoo, Head of Machinery·Equipment Office, Facility Division, SK Energy

| Please tell us about the Green maintenance that that Facility Division at Ulsan Complex is promoting.

Normally, waste and wastewater are generated even when we do machinery/device/pipe maintenance. However, in order to become “Clean CLX*”, we are focusing on Green maintenance work in three areas.

(*) Clean CLX: lsan CLX’s social value creation activities to create a clean and happy society, categorized by four sections: Clean Air, Clean Water, Clean Workplace, and Clean Life.

First, we try to minimize waste generation in various maintenance work. An example is the recycling of waste oil sand in the regular open inspection of tanks in crude oil storage areas in the first half of this year. This includes minimizing sanding in the tank plates**, and using eco-friendly products when replacing rotating machine parts.

(**) Tank plate: the steel plate on the floor or roof inside the tank. Tank plate sanding means coating the steel plate, and some waste is generated in this process.

▲ (Left) A crude oil storage tank at Ulsan CLX / (Right) Removed equipment at Ulsan CLX

Second, we reuse the removed equipment as training materials. Moreover, during regular maintenance, over 80% of the water used for heat exchangers is reused by applying a temporary recovery processor.

Third, in the case of perlites, which are used as a thermal insulation material for tanks/pipes, etc., we are practicing green maintenance by sorting recyclable perlites.

▲ (Left) The existing insulation material (perlite) is being ripped off from the surface of a at Ulsan CLX / (Right) It is possible to recycle the perlites by sorting them and sending them to a specialized processing company.

In addition, we are taking the lead in making Ulsan CLX a safer and more pleasant workplace by identifying 11 SHE (Safety, Health, Environment) elements to prevent serious accidents that may occur during maintenance work.

| Ulsan CLX has dramatically reduced pollutants by innovatively changing the use of electricity and generators during maintenance process. Could you tell us more about this?

▲ Hwang Sun-jae, Head of Instrument-Electricity Office, Facility Division, SK Energy

There are many cases where so-called “commercial electricity” that only needs to be plugged into a power outlet is not available at Ulsan CLX. In this case, the easiest way is to use a portable power generator. However, portable generators are noisy and they generates a greater amount of pollutants than we may think, because they do not have smoke reduction devices.

Ulsan CLX is trying to use less portable generators by improving facilities to supply commercial electricity to contribute to SK Innovation’s Net Zero goal.

▲ Ulsan CLX is supplying commercial electricity by improving facilities in the regular open inspection of tanks at the crude oil storage areas in the first half of this year.

We also made efforts to create Clean Air by reducing NOX and greenhouse gases using commercial electricity instead of portable generators in the the regular open inspection of tanks at the crude oil storage areas in the first half of this year. Furthermore, we have improved our working environment by reducing noises.

Click the video below to learn more about Ulsan CLX’s Green maintenance:

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin