SK Geo Centric

SK Geo Centric

The eleventh episode of SK Innovation’s endeavor to achieve Decarbonization will be about the Automotive Business Unit of SK Geo Centric (SKGC). Here, eco-friendly and lightweight materials are being developed to contribute to the development of electric vehicle ecosystem. Let’s meet Bae Sung-chan, Head of SKGC’s Automotive Business Unit to learn more about how Green Transformation is being taken through this business.

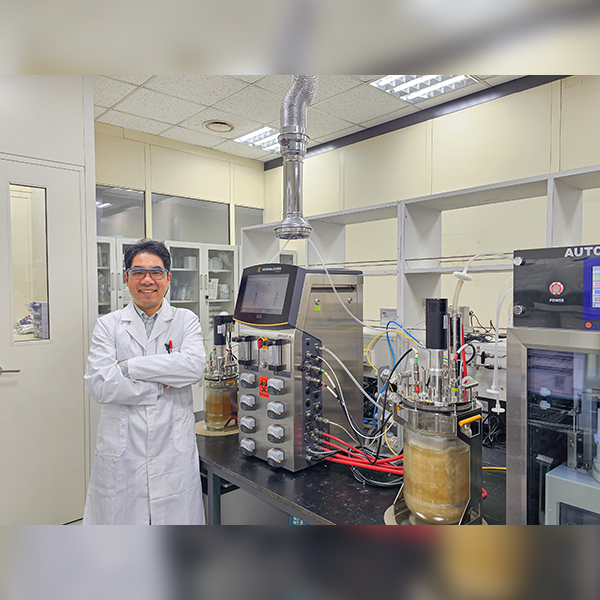

▲ Bae Sung-chan, Head of Automotive Business Unit, SK Geo Centric

ㅣ First of all, please tell us about the current status and prospects related to the shift to eco-friendly commercial vehicles.

Commercial vehicles account for about 9% of the total vehicles in the world, but they produce 40% of greenhouse gas emissions.

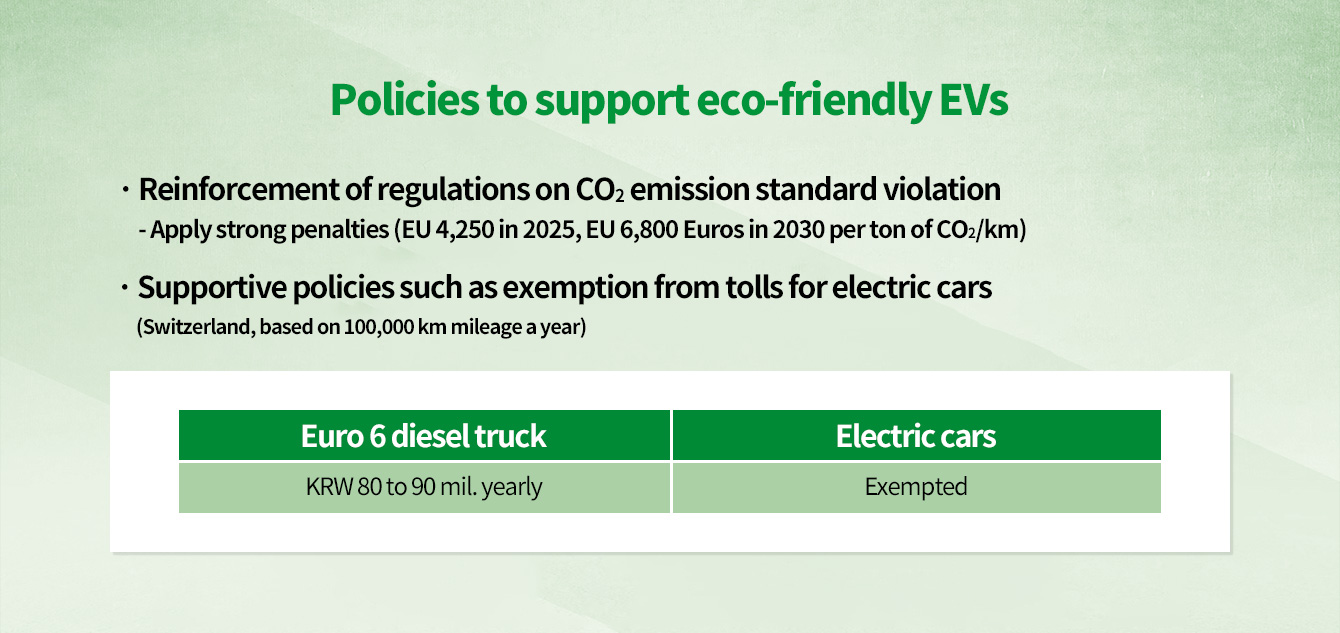

Recently, starting with the EU, emission gas regulations have been strengthened and more policies to support eco-friendly vehicles have been introduced, so eco-friendly commercial vehicles are rapidly being developed.

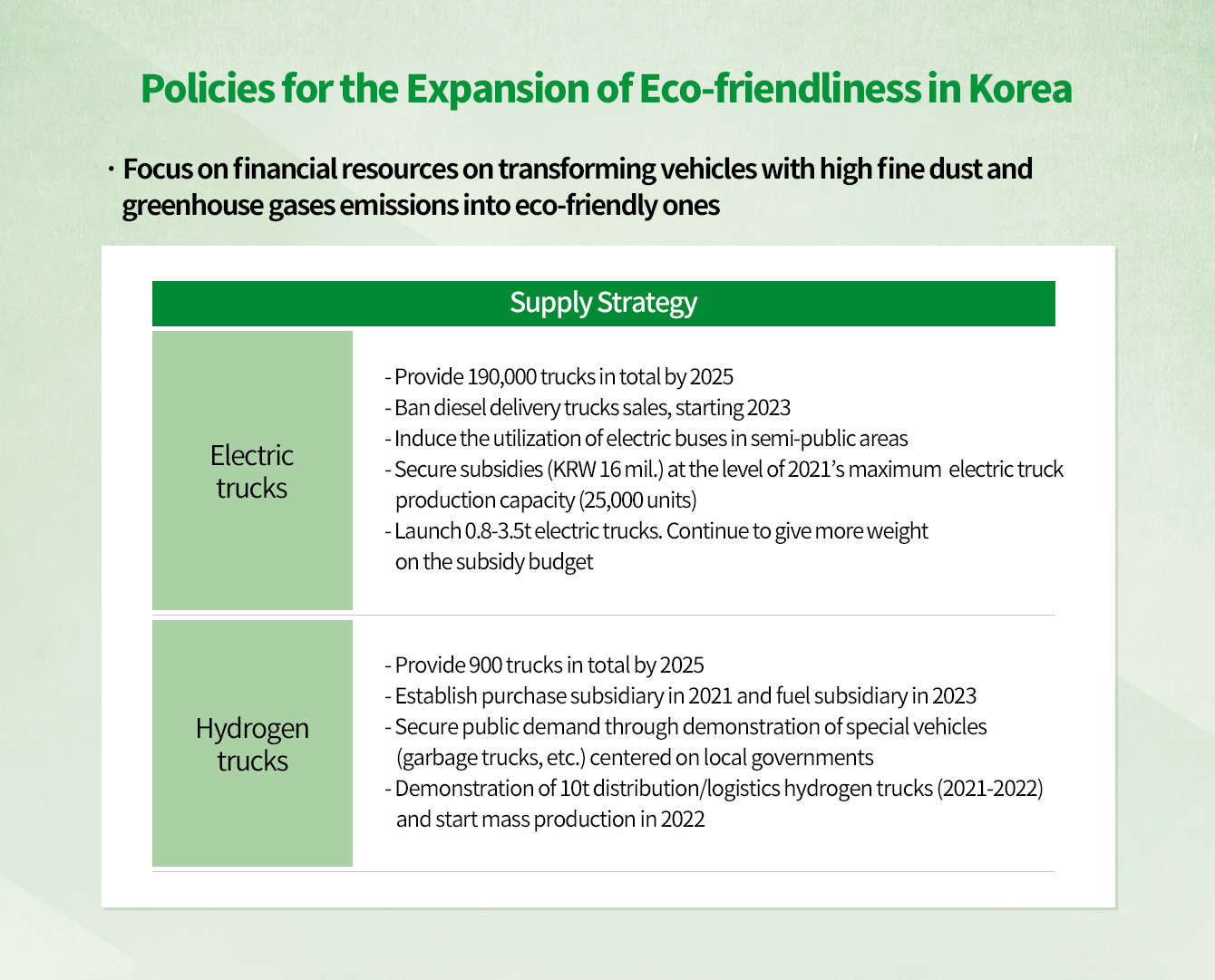

In Korea, in line with a related government policy, the supply of small EV trucks is expanding significantly, and as large hydrogen trucks are expected to be distributed in the future, the need for light weight commercial vehicles is expected to continue to grow.

ㅣ How is the “eco-friendly lightweight material business” of SKGC going?

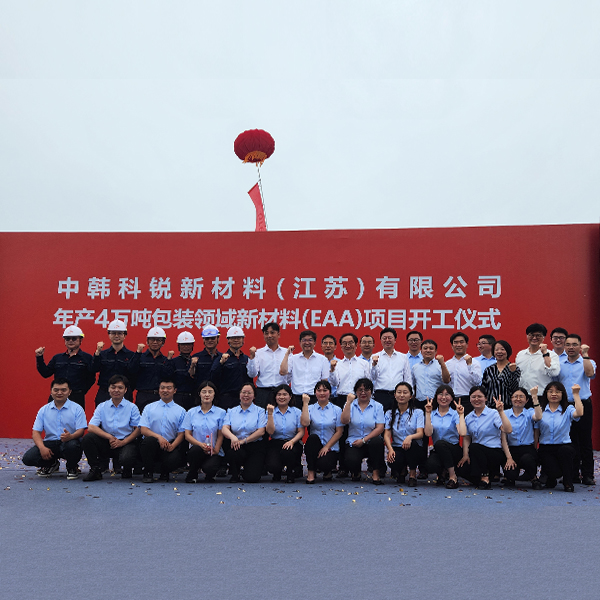

SKGC signed an MOU with POSCO in March this year to jointly develop steel-plastic composite materials for electric vehicles.

▲ SKGC and POSCO signed an MOU for the “Joint development of steel-plastic composite materials for electric vehicles” on March 8, 2021. (3rd from left: SKGC CEO Na Kyung-soo, POSCO CEO Kim Hak-dong)

It was followed by MOUs with the Korea Smart Mobility Association and CEVO Mobility, an electric vehicle manufacturer, in June and September respectively. Now we are conducting joint research and demonstration work to develop lightweight materials for ultra-compact electric vehicles.

▲ (Left) SKGC and the Korea Smart E-Mobility Association signed an MOU for the purpose of developing new materials to lighten the core parts of ultra-small electric vehicles in June 2021. / (Right) SKGC and CEVO Mobility signed an MOU to develop materials for ultra-small electric vehicles in Septemebr 2021.

Besides, we are promoting joint development of lightweight battery cases with Hyundai Motors and Hyundai Mobis. We are also promoting the application of lightweight materials to delivery vehicles of domestic logistics giants.

As such, SKGC is implementing green transformation in the automobile and transportation industries by collaborating with diverse value chain participants such as automobile OEMs, other material companies, and the logistics industry.

ㅣ Could you give more details about the “lightweight composite material” that is being developed?

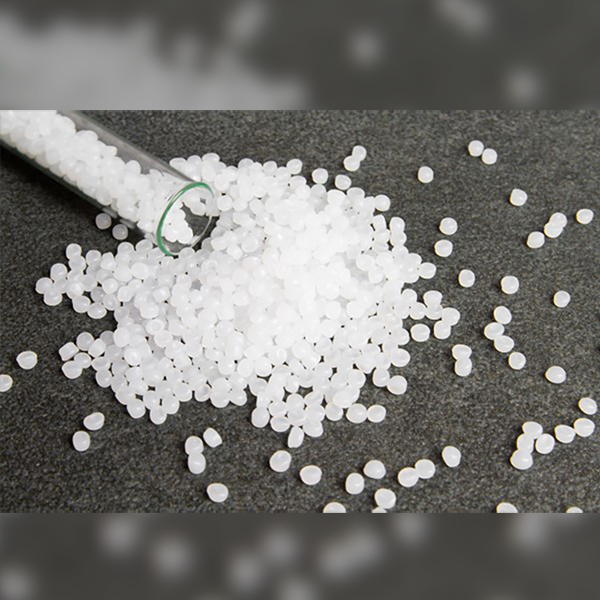

SKGC’s lightweight composite materials made of Uni-Directional (UD) Sheet, which is lighter in weight than existing metals, has no risk of corrosion, and low thermal conductivity.

In other words, as a material with light weight and good insulation performance, it can contribute to energy saving and carbon emission reduction. We have made a commercial vehicle top-box using this composite material and mounted it to an actual vehicle and currently we are in the stage of testing its durability. We plan to accelerate the development process by identifying the pros and cons in the production process and actual use, and then proactively improve them.

Also, we have specific cooperation projects with domestic logistics giants such as Hanjin, CJ, and Lotte to expand the applications of composite materials for commercial vehicles. We are also participating in the eco-friendly commercial vehicle conversion project with SK Energy and Logisquare.

ㅣ What are the expected effects of the eco-friendly lightweight materials?

▲ Top box equipped vehicle using eco-friendly lightweight materials of SK Geo Centric

Compared to a 1-ton diesel truck with steel top box, the total weight can be dramatically reduced as much as 100kg. In terms of fuel efficiency, it is an eco-friendly recyclable solution as fuel consumption can be reduced by 0.5 liter when driving 100km.

Accordingly, we plan to foster it as one of SKGC’s major eco-friendly solutions in the future because it has economic and social effects of reducing fuel efficiency and carbon emissions. Going forward, SKGC will accelerate the development of eco-friendly lightweight materials that are both lightweight and safe, so that we can realize the eco-friendly strategy of the automotive materials business and contribute to the creation of the EV industry’s ecosystem. We have broken away from the traditional working style and removed boundaries, and experienced that a change of thinking and taking challenge fearlessly can lead to good results.

So we will keep making efforts to practice ESG management at the forefront by creating economic values as well as social and environmental values.

Click the video below to see the full interview:

– [Card News] Cars made from plastic?!

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin