SK Incheon Petrochem

SK Incheon Petrochem

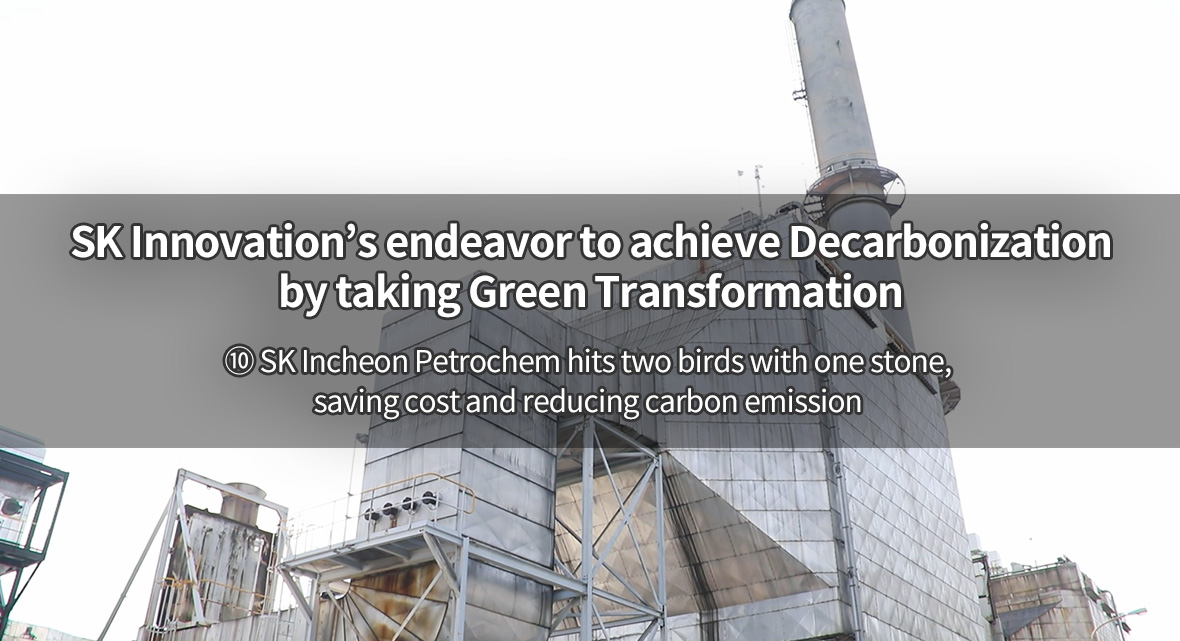

In the tenth episode, we’d like to introduce SK Incheon Petrochemical (SKIPC), a subsidiary of SK Innovation that has achieved both energy and carbon emission reduction through cost-saving innovation. Let’s hear the story of SKIPIC’s Green Transformation from Lee Kyu-ho, Head of SKIPIC’s Refinery & Aromatic Plant.

▲ Lee Gyu-ho, Head of Refinery & Aromatic Plant, SK Incheon Petrochem

ㅣ Please introduce the cost-saving innovation that SKIPC has achieved to implement the green transformation strategy?

Cost-saving innovation means to innovate the way we reduce cost. Unlike the existing optimization method for each unit, from the perspective of optimizing the entire plant, we found ideas and implemented improvement plans without boundaries between units. As a result, new and diverse attempts were made, and we were able to approach our goal of implementing the green transformation strategy by reducing both energy consumption and carbon emissions.

ㅣ Could you show us a specific case?

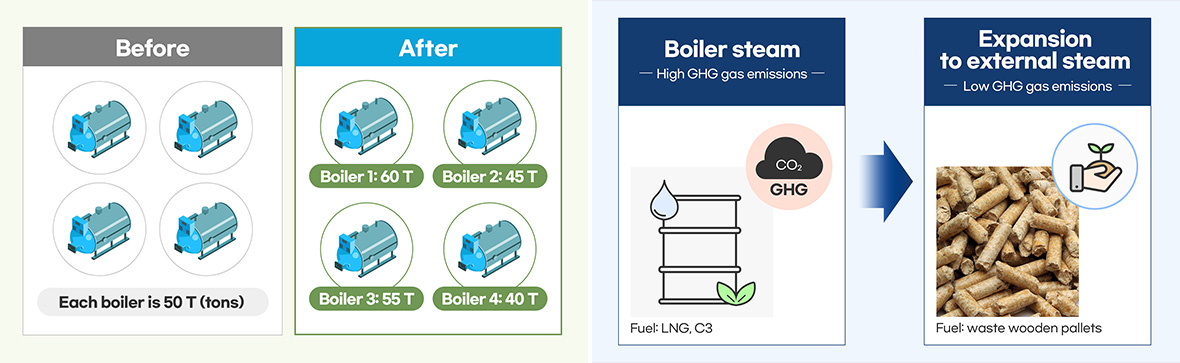

First, we have analyzed the efficiency levels of steam producing boilers by boiler/load unit and established optimal operation guidelines and then operated them based on the new guidelines.

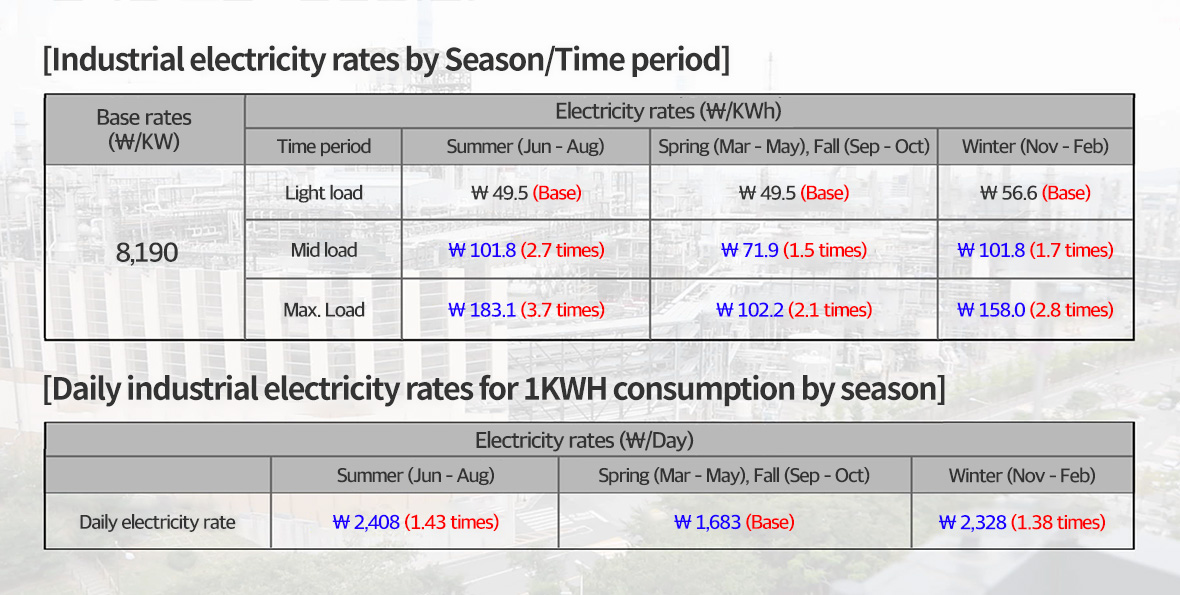

The second example is about electricity use. Electricity rates vary greatly by season and load, so we looked for ways to take advantage of this situation. For example, for large-capacity rotating machines that are operated intermittently, we have derived and implemented optimal operation plans by avoiding peak load times and considering the efficiency level of each pump A/B switch and the difference in rates by season.

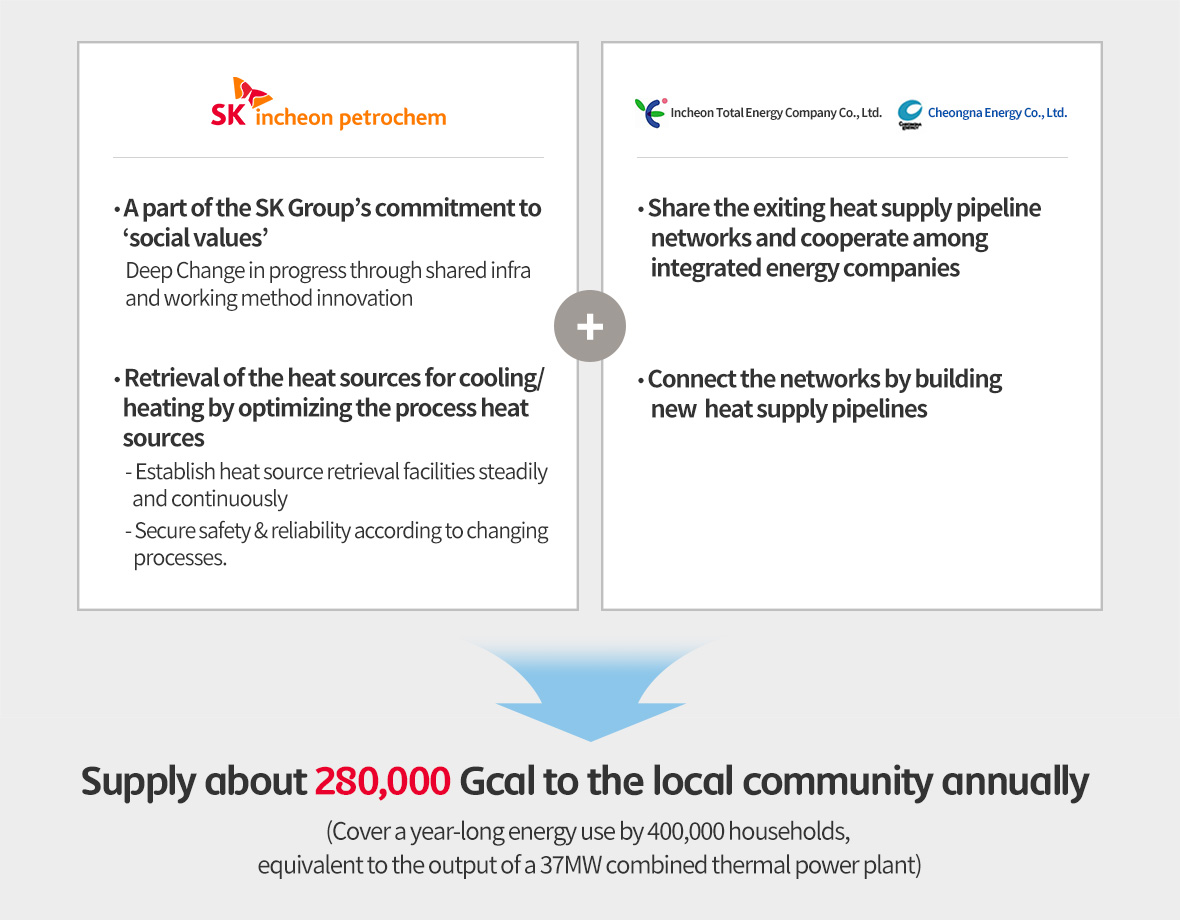

Third, fuel. Since 2019, SKIPC has been carrying out a project to recover heat sources from the process and supply them to a community energy services company to recycle them as heating and cooling energy in the local community and is also conducting a second phase investment project to additionally recover heat sources. Some of them will be sold and most of them will be used as heat sources for internal processes. It is expected to reduce fuel use and emissions, thereby creating both economic and social values at the same time.

Another example is the use of water. Previously, tap water was used for industrial purposes, but from early next year, we will use recycled water from effluent water coming from a nearby sewage treatment plant. We expect to create an economic value of up to KRW 1.1 billion per year and reduce a social cost of KRW 2 to 3 billion per year by not using tap water.

ㅣ Lastly, would you like to say a word of promise for the future for Green Transformation at SKIPC?

We have broken away from the traditional working style and removed boundaries, and experienced that a change of thinking and taking challenge fearlessly can lead to good results. So we will keep making efforts to practice ESG management at the forefront by creating economic values as well as social and environmental values.

Click the video below to see the full interview:

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin