SK Geo Centric

SK Geo Centric

▲ Daniel Solomita, CEO of Loop Industries (left), and Na Kyung-soo, CEO of SK Geo Centric (right) posed for a commemorative photo at Loop Industrics’ facility during SKGC’s North America tour in November 2021

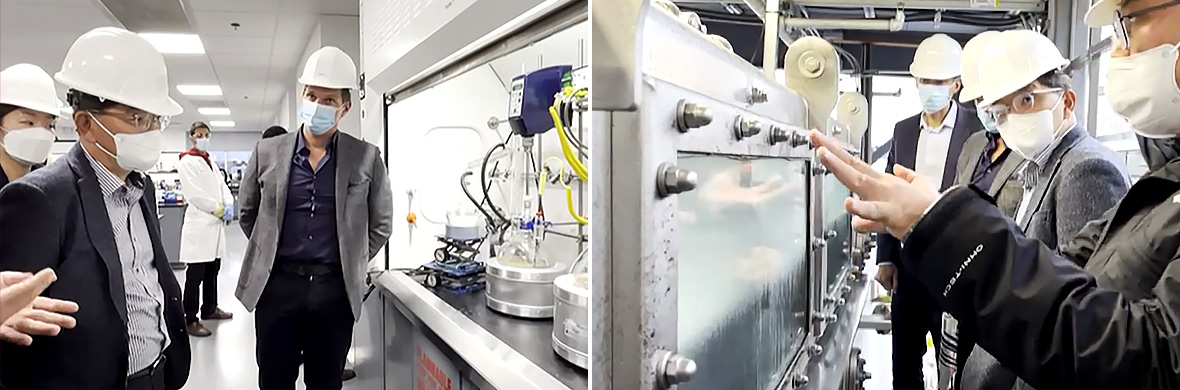

SK Geo Centric is proposing a roadmap for a circular plastics ecosystem through its global partnering, paving the way to give a fundamental answer to plastic wastes. In November, the company’s CEOs and leaders visited three North American partner businesses to expedite the three essential technologies for chemical recycling in its full-scale global action.

In the first episode of this series, where we followed SK Geo Centric leaders in their North American tour, let’s go to Quebec, Canada, to check the chemical recycling facility of Loop Industries. Here we can see how new plastic material is extracted from wasted PET, carpet, and other fibers.

▲ An introductory video featuring Loop Industries’ depolymerization technology – Source: Loop Industries

Loop Industries owns an innovative technology for recycling discarded PTE bottles/waste textiles, and SK Geo Centric invested USD 56.5 million (about KRW 66.3 billion) in the company last June to acquire a 10% stake and exclusive rights over Asian region. It allowed SK Geo Centric to secure Loop Industries’ depolymerization* technology, a breakthrough technology for plastic recycling, as well as exclusive production/sales rights for r-PET (Recycling Polyethylene Terephthalate) in Asia.

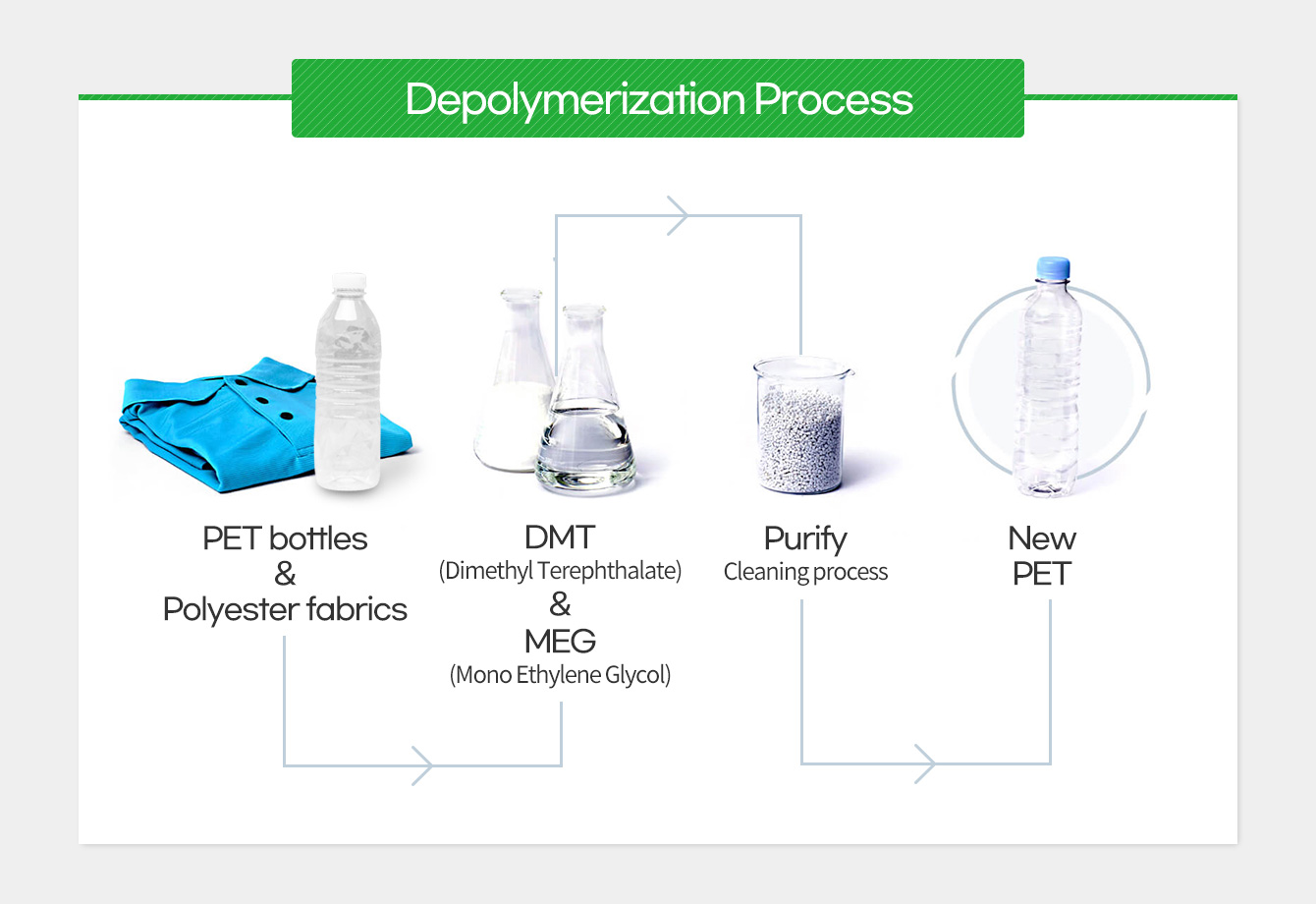

(*) Depolymerization: It is a process that breaks down polymers into monomers to return macromolecules that constitute plastics like colorful PET bottles and polyester fabrics to their basic plastic ingredients.

▲ Last June, Daniel Solomita, CEO of Loop Industries, and Na Kyung-soo, CEO of SK Geo Centric, signed a strategic investment MOU for the purpose of investing in Loop Industries to secure stakes and the company’s depolymerization technology, among others.

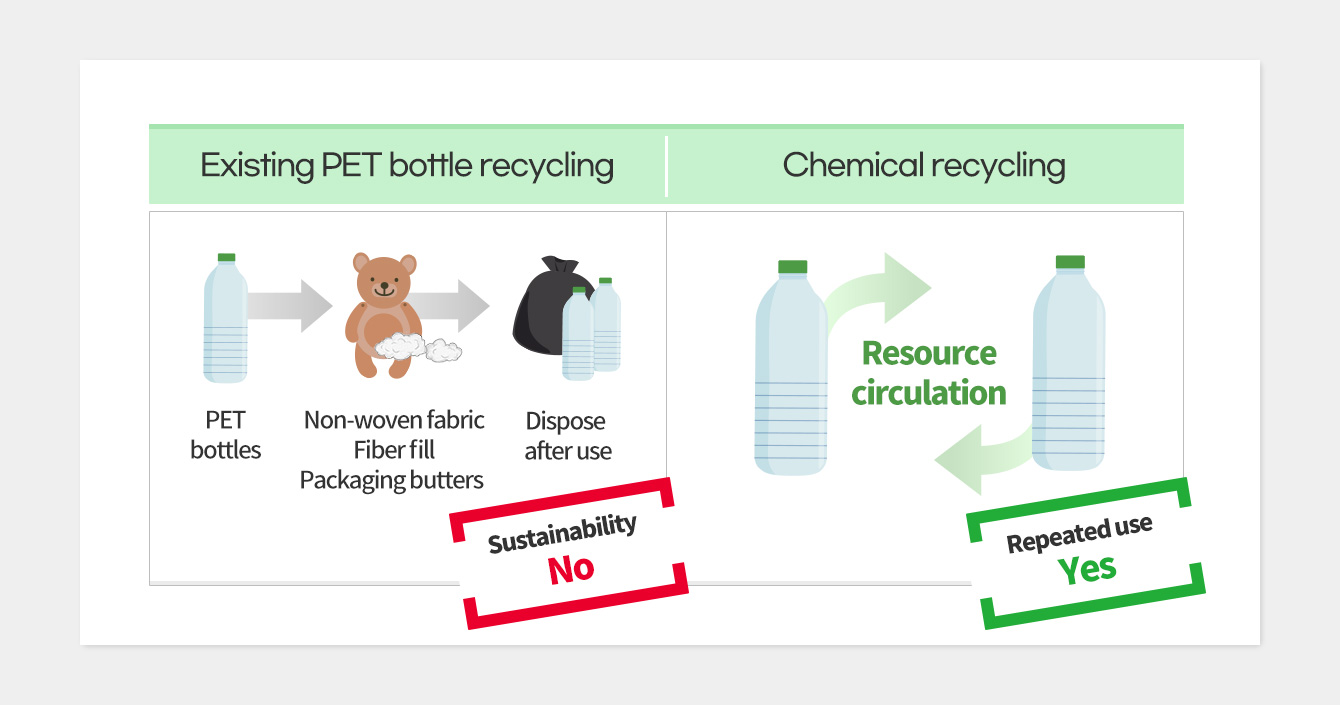

Existing PET bottle recycling technologies use a one-dimensional recycling approach that only allows them to be used two or three times as materials in low-value-added products like nonwoven fabric fibers and stuffed animal fillings, among other things. Chemical recycling technology, on the other hand, can continually reconstitute PET bottles without losing their original values, allowing for true plastic resource circulation. As such, a circulation system that re-makes PET bottles from PET bottles would be a game-changer in terms of environmental and waste issues. That is why chemical recycling technology has risen to prominence.

Depolymerization is well known to be the most complex of several chemical recycling methods. In the case of the United States, all carpets, commonly used household items, and dirty PET bottles are incinerated. It was difficult to comprehend that such materials could be chemically decomposed at low temperatures to produce transparent PETs in their pure raw condition.

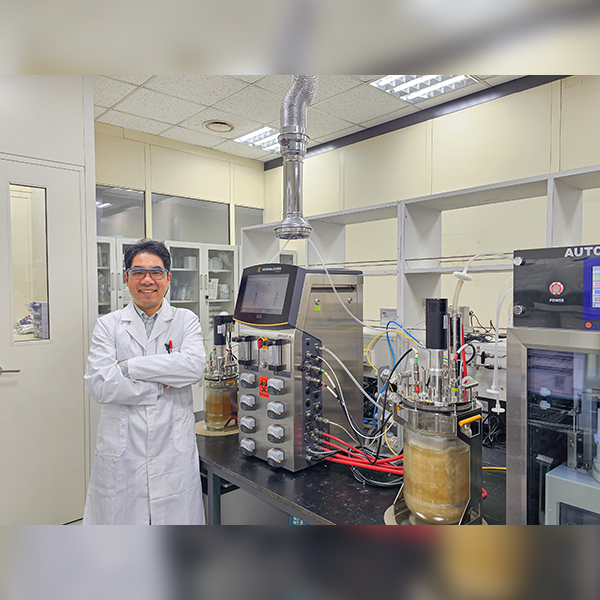

During our tour to Loop Industries, we were able to see how fragmented PETs, colored PET, and lumps of polyester fabrics are used as raw materials in the depolymerization process.

▲ Raw materials for depolymerization (from the left, fragmented PETs, finely cut color PETs, and lumps of polyester fabrics)

Simply put, depolymerization technology is the process of breaking down polymers into monomers. It can be said that the gist of this technology is to extract the purest results with the least amount of energy.

▲ Na Kyung-soo, CEO of SK Geo Centric (left), paid a visit to Loop Industries in Quebec, Canada, in November to see its manufacturing facilities and depolymerization technologies.

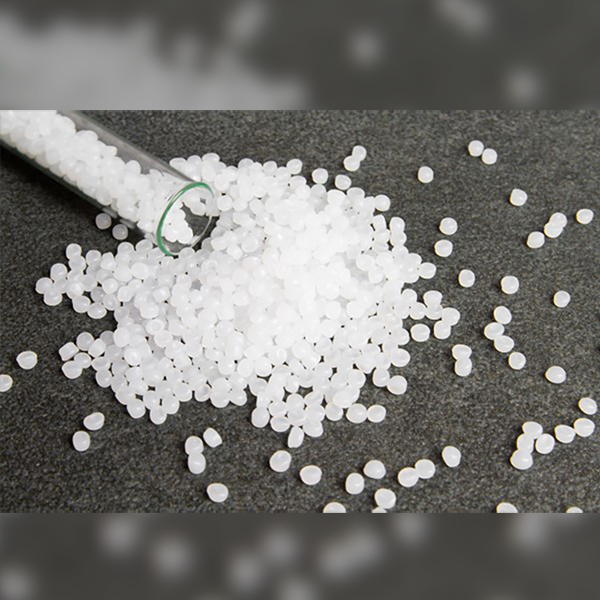

After the first treatment, carpets, polyester textiles, and color PET bottles will be placed in a reactor for crumbing, followed by multiple phases of purification, to generate PETs that are as crystal clear as those just made from crude oil.

▲ Introduction to depolymerization technology by Loop Industries – Source: Loop Industries

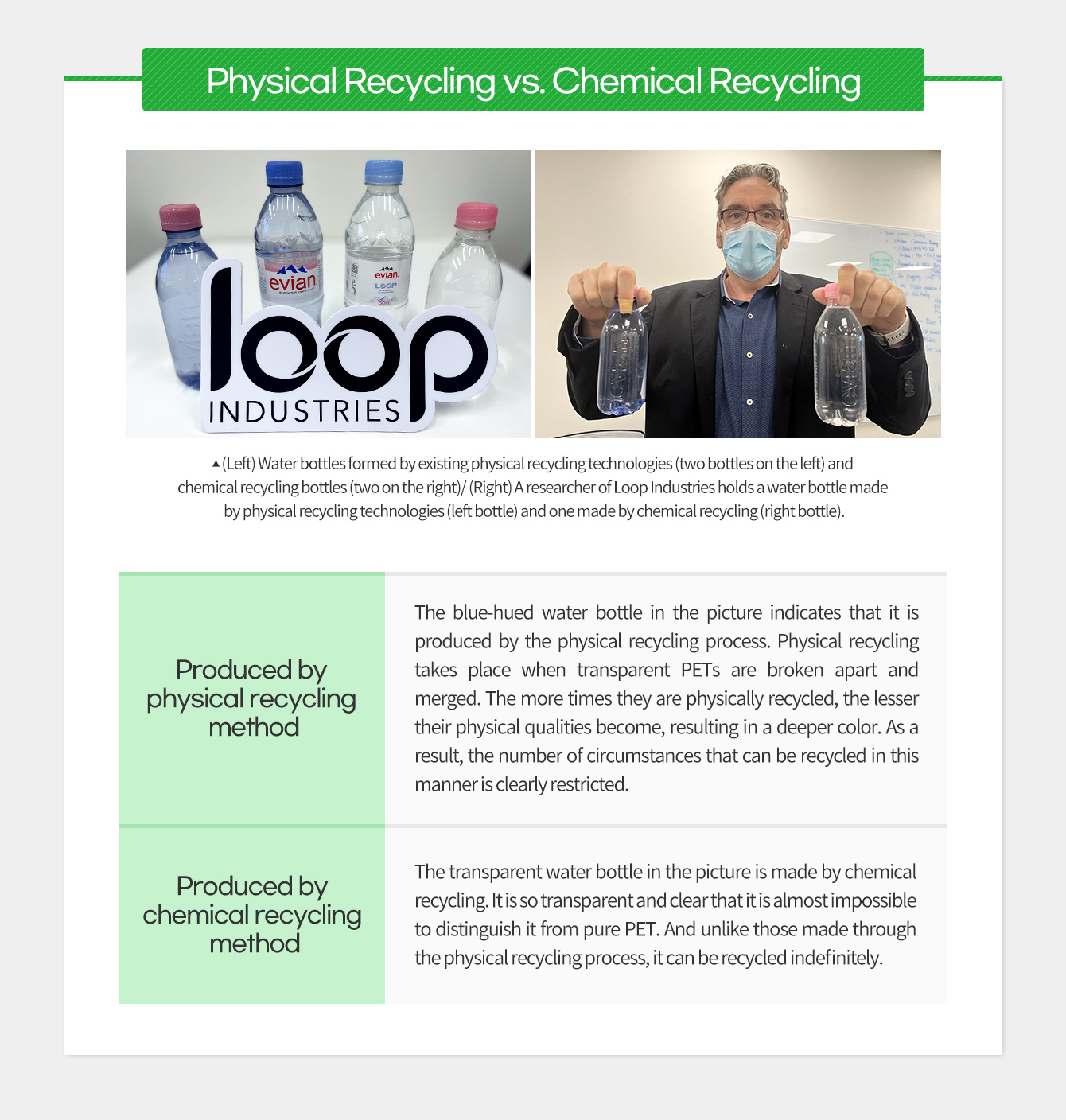

This transparent PET is comparable to pure PET derived from crude oil in terms of property and quality, and it is clean enough to be used in food or spring water packaging. Loop Industries’ PETs meet FDA (Food and Drug Administration) standards and regulations, and they have applied to a pilot production of the world’s first chemically recycled water bottles in partnership with Evian, a Danone spring water brand in France.

In the first part of this year, Evian, which has been collaborating with Loop Industries for four years, expects to debut spring water products in 100% chemically recycled water bottles in South Korea. Evian will be able to get a step closer to its goal of replacing all of its bottles with recycled PET bottles by 2025 thanks to Loop Industries’ PET bottles.

Loop Industries is establishing a virtuous cycle system for plastic resources in collaboration with a number of multinational brands, including Danone, and is now constructing a commercial manufacturing unit in Quebec, Canada, that is expected to be completed by the end of 2023. In addition, the company is intending to build a plant in France in order to get into the European market, as well as expand into the Asian region with SK Geo Centric.

South Korea is on the verge of the full introduction of physical recycling technology in January next year. To achieve this, the Minister of the Environment implements a “separate recycling system for clear PET bottles” in order to create a clean waste PET collection network.

Against the backdrop, SK Geo Centric is seeking to secure three major chemical technologies, including depolymerization. Furthermore, the corporation will build the world’s largest chemical plastic recycling cluster in South Korea by constructing a large-scale plastic recycling complex.

Currently, a number of plastics have no choice but to be drained into the ocean or incinerated once they have served their purpose. However, it appears that the days are numbered before these plastic wastes are recycled and reborn in order to create a circular plastics economy and contribute to the formation of a carbon-neutral society.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin