SK Energy

SK Energy

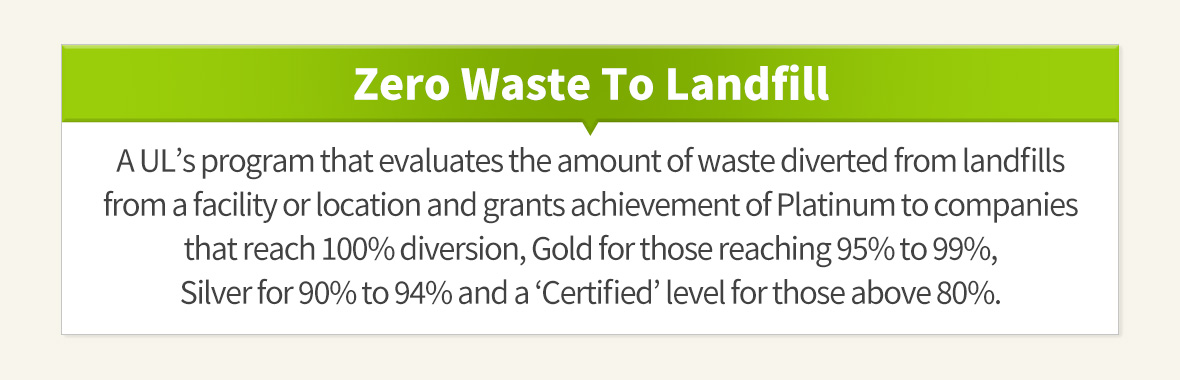

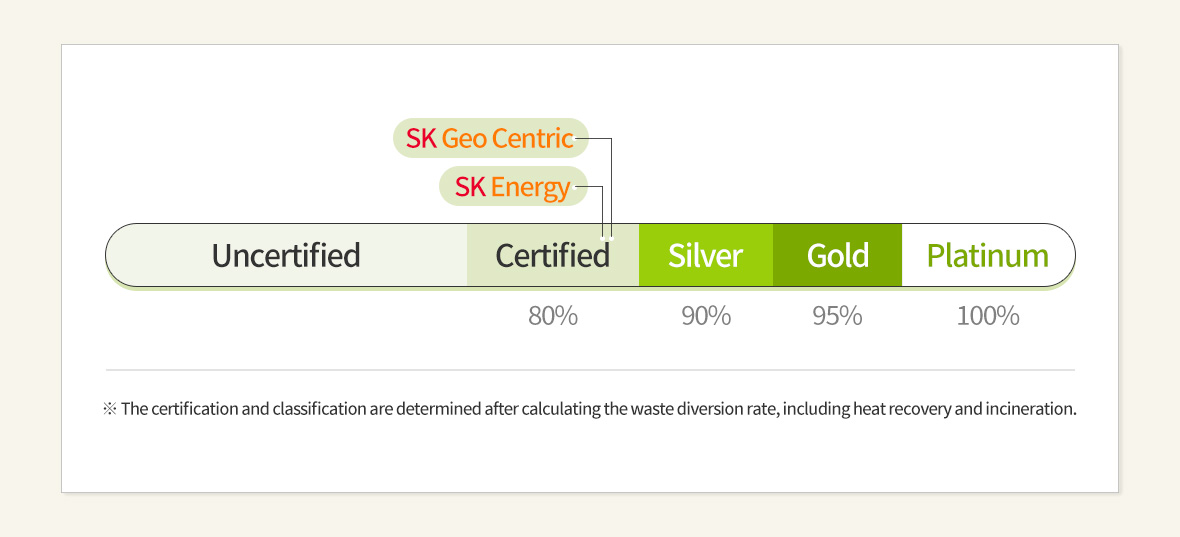

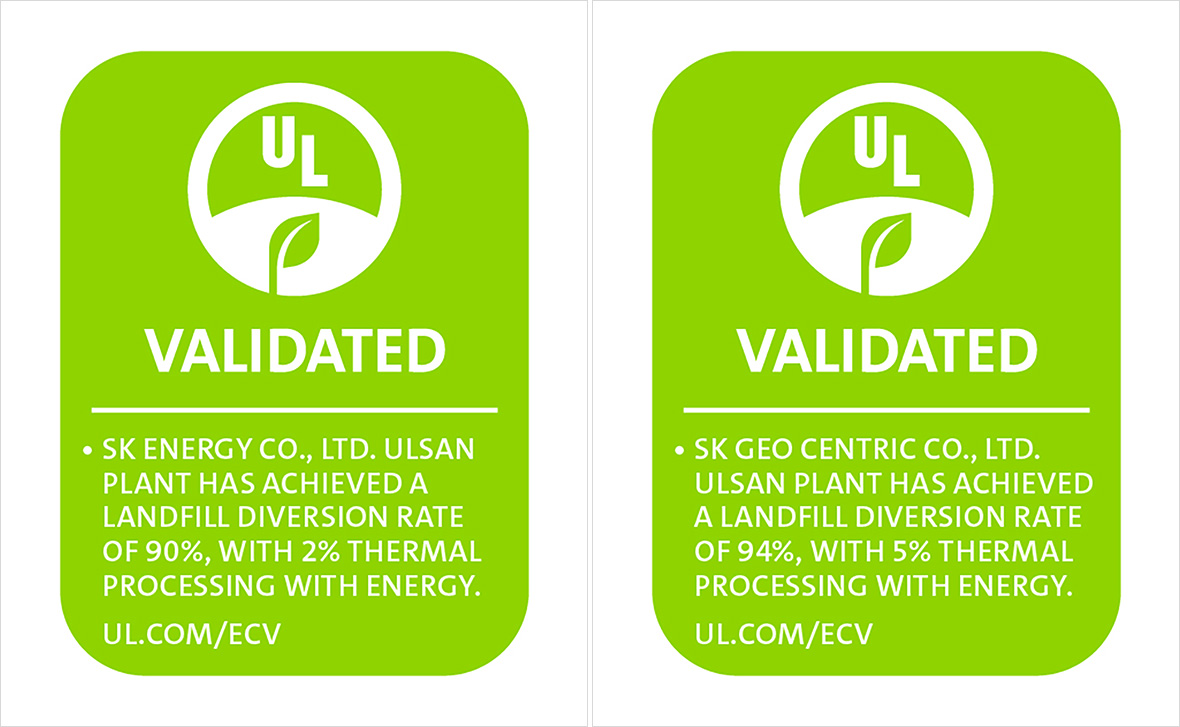

On July 20, SK Energy and SK Geo Centric acquired the Zero Waste to Landfill (ZWTL) validation, the international certification that is given to companies with an 80% waste diversion rate and above. This achievement is meaningful as it proves SK Innovation’s genuine effort to implement the Carbon to Green strategy.

Getting the ZWTL certification is challenging as UL (Underwriters Laboratories) is known for its high standards and criteria in evaluation. Moreover, this certification lasts only a year, which means if a company does not strive continuously to keep the standard, it will be unqualified to maintain the verification. At the money, only about 100 international companies is owning the ZWTL certification. These include Foxconn, Bausch + Lomb, Starbucks, to name a few.

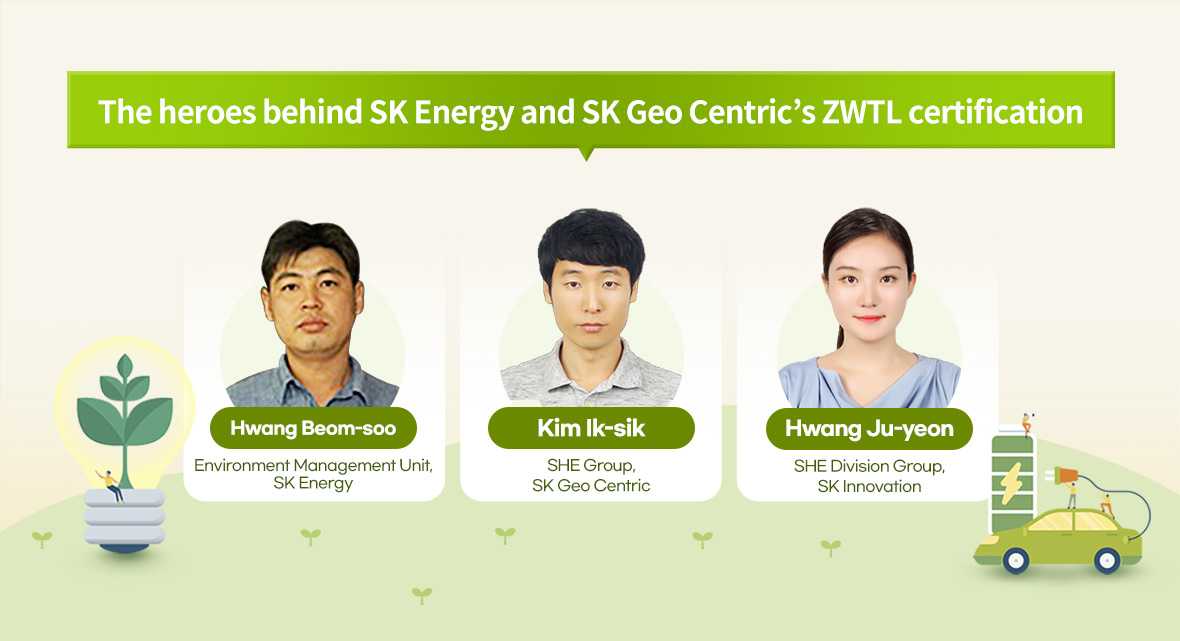

On top of that, SK Energy and SK Geo Centric’s acquirement of the ZWTL certification is even more remarkable because of multiple challenging limitations of petrochemical industry. Let’s meet Hwang Beom-soo (Environment Management Unit, SK Energy), Kim Ik-sik (SHE Group, SK Geo Centric), and Hwang Ju-yeon (SHE Division Group, SK Innovation) to learn more about the behind stories of how the companies acquired the certification.

Q1. Congratulations! You all have worked hard for the certification. We heard that acquiring the ZWTL certification is really challenging, isn’t it?

▲ The ZWTL validation marks SK Energy and SK Geo Centric earned.

It is true that ZWTL is a certification that is hard to acquire. Besides, it is undeniable that the petrochemical industry has many limitations regarding the landfill diversion, there is hardly any client who demands ZWTL validation in our industry. Even so, we decided to take on this challenge, because “Zero Waste” is the goal that the whole world must achieve. Here at SK Innovation Ulsan Complex (Ulsan CLX), where petroleum and petrochemical products of SK Energy and SK Geo Centric are produced, we believe that acquiring ZWTL certification would be a particularly effective way to share the “Carbon to Green” vision of SK Innovation. So that’s why we went ahead with it.

Q2. I am sure that checking the “feasibility” would have been a crucial factor when you start preparing for the verification. As ZWTL looks at the “waste diversion rate,” I wonder where the rate for Ulsan CLX stands in comparison to the companies across the globe.

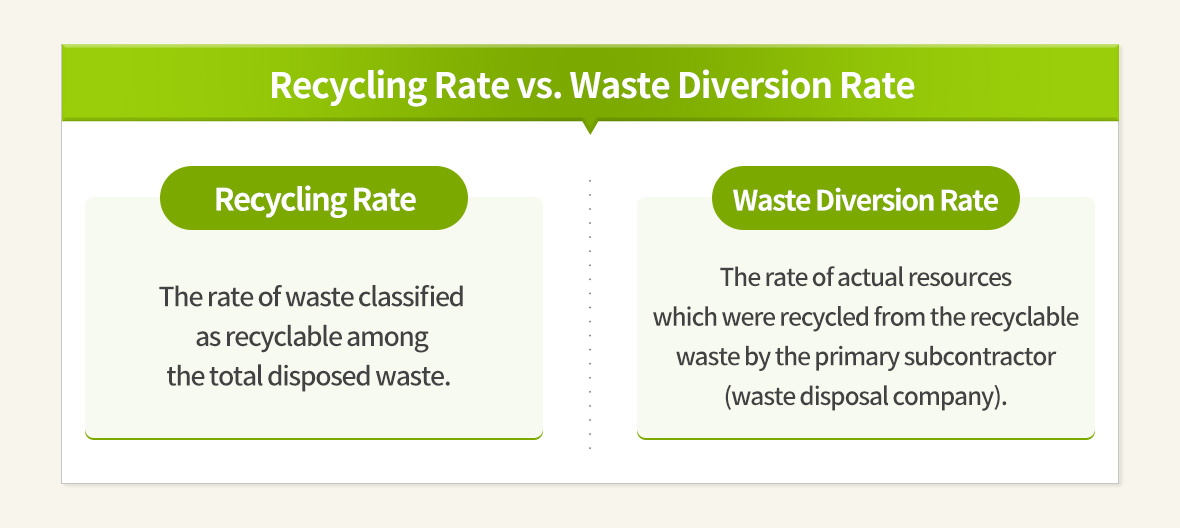

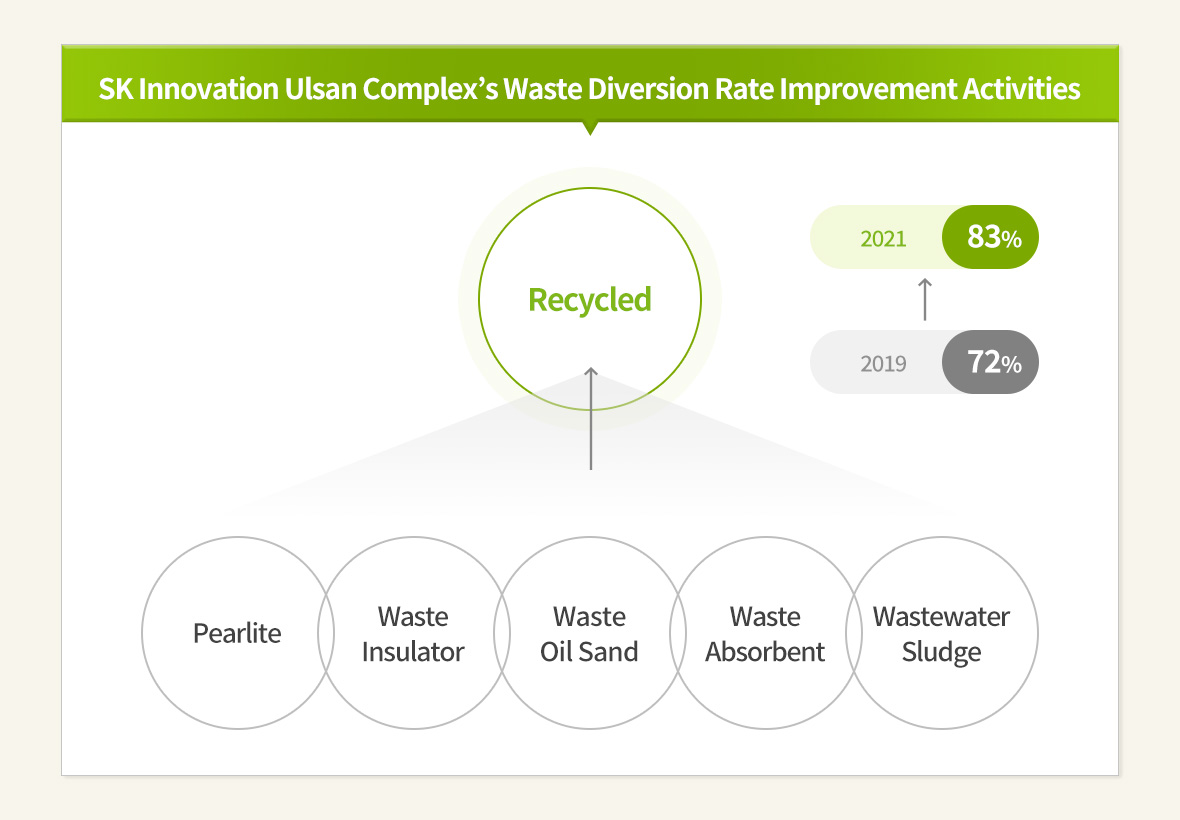

First, I think it’s important that we delineate the differences between the “waste diversion rate” and the “recycling rate.” The waste recycling rate is typically about the waste classified as “recyclable” among the waste materials disposed at Ulsan CLX. On the other hand, the waste diversion rate of ZWTL refers to how well the primary subcontractor or the waste disposal company was actually able to recycle the waste materials. When we started checking the feasibility, Ulsan CLX’s recycling rate was already at an outstanding level, and the waste diversion rate was confirmed to be around the expected level as well. However, since Ulsan CLX aspires for a higher level instead of being satisfied with the standard industry level, we plan to strive more to reach the waste diversion rate of leading industries.

Q3. There must have been a lot of hurdles along the way.

This is the first time we tried to achieve this certification, so our only strategy was to be as dutiful as possible. Moreover, we were a bit stunned because the standard got stricter compared to the previous year. When the standard is set higher, there is also a higher chance of failing, so we hurried to secure the additional materials and come up with responses, and that was some work, really. But I suppose that we responded well, given that we bore good results.

(1) Pearlite: Aggregates found in insulations that are used to prevent heat loss in pipes and devices for oil refining or petrochemical processes. It’s extremely lightweight and comes out after grinding or sintering perlites or obsidians.

(2) Waste Oil Sand: Oil and sand are mixed and used to prevent erosion in the surface of the tank bottom plate, where petroleum-based materials and products are stored. In the process of repairing or exchanging the tank, this waste oil sand is created.

(3) Wastewater Sludge There are organic matters in the wastewater which are created when products are produced. These matters are treated at the wastewater disposal plant using microorganisms. In the process, it gives out this microorganism residue.

Q4. We heard that you are already preparing for the 2023 certification even though you have just acquired it this year.

Our application to maintain the certification will happen in the first quarter of next year, which is about the time when the 2022 performances would be wrapped up. We plan to get ready with any additional activities for improvement and response plans until then. At the moment, we’re closely cooperating with SK Innovation Institute of Environmental Science & Technology, particularly on the development of waste recycling technology, the improvement of the purge* method to recycle landfill waste, and the segregation and treatment of recyclable waste. I’m hopeful that there will be visible results as well.

(*) Purge: The process of removing oil and other substances smeared inside the devices and pipes using steams, nitrogen, and a closed system before any repair and maintenance.

Q5. Both getting validated and maintaining that ZWTL certification are not easy at all. That must attest to something. Do you have any other message to our readers before we end this talk?

As I mentioned a while ago, rather than “improve the numbers”, we need to “enhance the actual waste diversion rate.” Thus this is not a one-off mission or short term project, it must become a “habit”. Once all the members cultivate the habit of approaching their work from the perspective of waste diversion, I believe that the dream of getting the highest classification will not be far-fetched.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin