SK Energy

SK Energy■ To upgrade facility management and operation by applying AR and IoT technology to plant sites

■ Collaborating on joint business development, aiming to “secure an unrivaled position in the smart plan field”

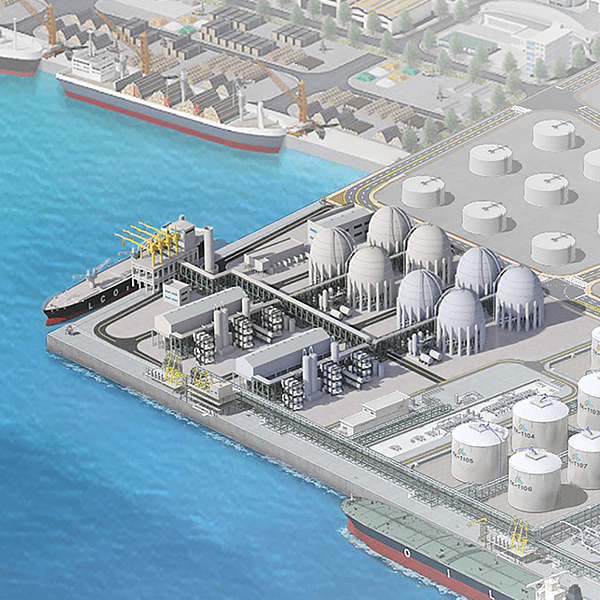

SK Energy decided to commercialize Smart Plant Solutions that combines digital technologies such as Internet of Things (IoT) and Augmented Reality (AR) with previously built smart plants, aiming for not only Korean energy and chemistry industries but also global market.

On February 21 (KST), SK Energy announced that the company signed a strategic business agreement with PTC Korea to build and operate a smart plant. The signing ceremony was held on the same day at SK Happy Town in Ulsan, South Korea. PTC is a global software company that provides platforms and solutions for digital innovation such as IoT and AR.

Through this agreement, the two companies decided to further enhance SK Energy’s self-developed next-generation facility management system OCEAN-H (Optimized & Connected Enterprise Asset Network Hub) by applying PTC Korea’s software technology.

*OCEAN-H: a system that systematically accumulates data on energy and chemical industry facilities within factories to improve efficiency and safety in plant operations

In addition, SK Energy plans to further this cooperation to commercialize Smart Plant Solutions in Korean energy and chemical industries and accelerate overseas market entry by utilizing PTC’s global networking.

The two companies have been collaborating since 2022 in the construction of a smart plant that SK Energy first introduced in the energy and chemicals industries, where process automation was mostly implemented, in 2016 to increase production efficiency and process stability by converging cutting-edge ICT technology.

As part of their cooperation, the companies have already built an AR-based smart scaffolding system and applied it on construction sites.

The smart scaffolding system is a system that applies AR to scaffolding that must be installed for worker safety at various plant construction sites such as routine maintenance. Using ground recognition technology (Ground Target), it became possible to measure the height and area of the scaffolding and virtually stack the scaffolding to estimate the amount of work more accurately. This increase work efficiency by significantly improving errors caused by existing manual work.

Furthermore, the two companies are also building a piping design and quality inspection system using AR technology. Previously, drawings of complicated piping installed on sites were created manually, but with the implementation of AR, it is expected that many of the risk factors associated with field work will be eliminated and the inefficient work environment will be improved.

“Effective utilization of digital technology brings about enormous benefits in addressing manpower shortages in industrial sites,” said Kim Sang-gun, Country Manager of PTC Korea. “We will continue to cooperate closely with SK Energy to ensure that the smart plant business produces tangible results.”

Seo Kwan-hee, Head of Engineering-Maintenance Division of SK Energy commented, “Through this partnership, both companies expect to create broad opportunities for cooperation and develop new business models.” “SK Energy will secure an unrivaled position in the market by securing expertise in smart plant construction and operation.”

[Photos]

(Photo 1) Seo Kwan-hee, Head of Engineering-Maintenance Division of SK Energy (3rd from the left) and Kim Sang-gun, Country Manager of PTC Korea (4th from the left) are taking commemorative photo after signing an MOU for commercializing Smart Plant Solution.

(Photo 2) Members of SK Energy are implementing a smart scaffolding system at the SK Innovation’s Ulsan Complex (Ulsan CLX) site.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin