SK Energy

SK Energy

▲ The Solid Bed Merox (SBM) Process at SK Innovation Ulsan Complex

The Solid Bed Merox (SBM) refers to the process of producing aviation fuel, and it requires raw kerosene as a raw material, so it contains a large number of substances that give off unpleasant smell and erode facilities. Therefore, the filtering task in the SBM process is significant. The clay in the clay filter(1) must be exchanged regularly, and a large amount of waste, spent clay(2), is excreted in the process, all of which has been land-filled up until recently.

(1) Clay Filter: This filter is composed of clay-type small particles, and it removes impurities like surfactant and metallic compounds that are melted in the kerosene.

(2) Spent Clay: Spent clay refers to the used-up clay that cannot filter impurities anymore in the clay filter.

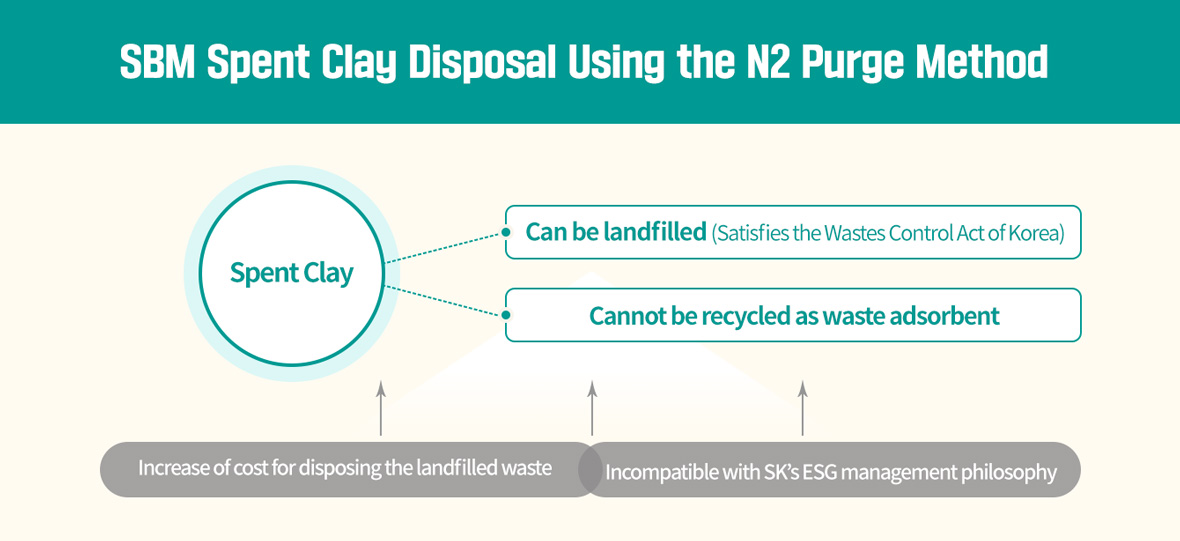

SK Innovation Ulsan Complex (Ulsan CLX) sought various ways to put an end to the practice of land-filling the spent clay in the SBM process and recycle it as a waste absorbent. However, it is a challenging task because the spent clay satisfied the standards of disposing of the designated waste, but it showed a high level of remaining hydrocarbon (H/C) and stench that cannot be recycled as waste absorbent. In addition, the cost of disposing of the land-filled wastes kept increasing. On top of that, this disposal process directly clashed with the ESG management philosophy of the company.

After studying the problems, three members of the Petroleum Production Division of SK Energy based in Ulsan CLX reached an innovative solution: “to abandon the existing standards.” The three members who proposed this drastic change are called the “ESG Avengers” of Ulsan CLX, and they include Lee Chae-gung, the General Foreman of Refinery Operation Unit 1, and two Process Technology Engineers Chae Myeong-ju and Kim Seung-wan.

Up until today, the traditional method of eliminating the H/C substance within the spent clay was N2 Purge(3). But the ESG Avengers took the challenge of reviewing the Steam Purge(4) method, which relatively contained more moisture than the old one.

(3) N2 Purge: This method gets rid of remaining substances such as H/C or inflammable and combustible gas stuck in a closed area or device by using nitrogen (N2).

(4) Steam Purge: The method is the same as the N2 Purge, except that it uses steam to get rid of the remaining substances.

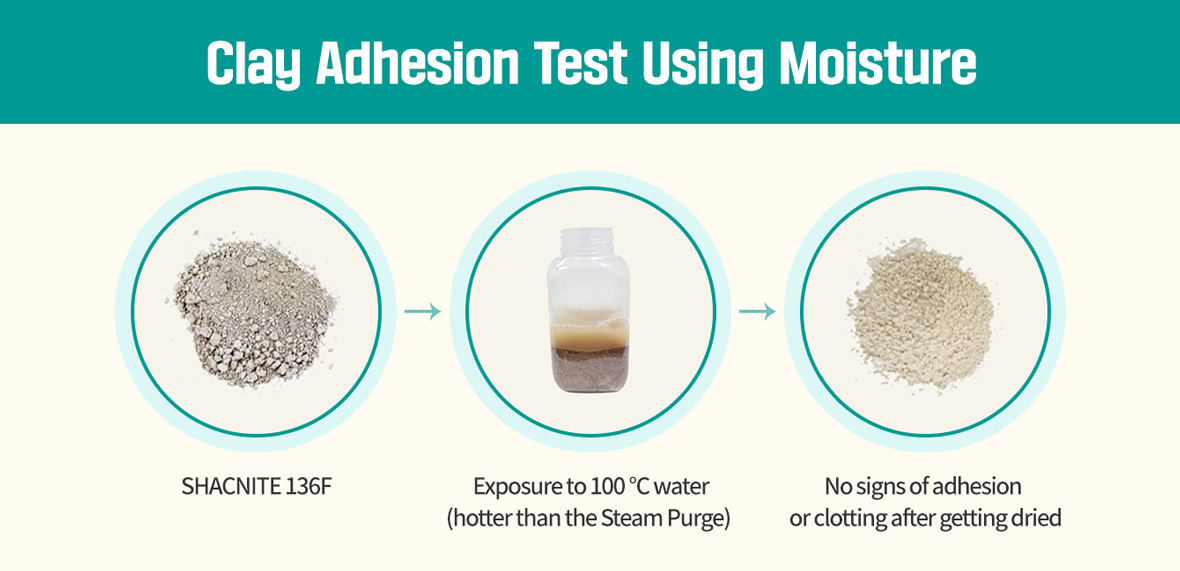

In fact, the Steam Purge method had been adopted once in the past, but it did not work well because the moisture caused the spent clay to clot and get adhered. However, the ESG Avengers made use of the lesson from the previous failure and conducted a more thorough and extensive review of the method, discovering significant differences.

First, the clay (SHACNITE 136F) currently used at the Ulsan CLX contained fewer impurities than the ones used in the past. Besides, the SiO2, which is the major substance, had little chance of getting adhered to by the moisture.

Second, they found that the license manual also indicated that the Steam Purge could be conducted within 48 hours to unload the spent clay without any adhesion. After this finding, the ESG Avengers conducted several more tests to finally became ready to dive into actual tests.

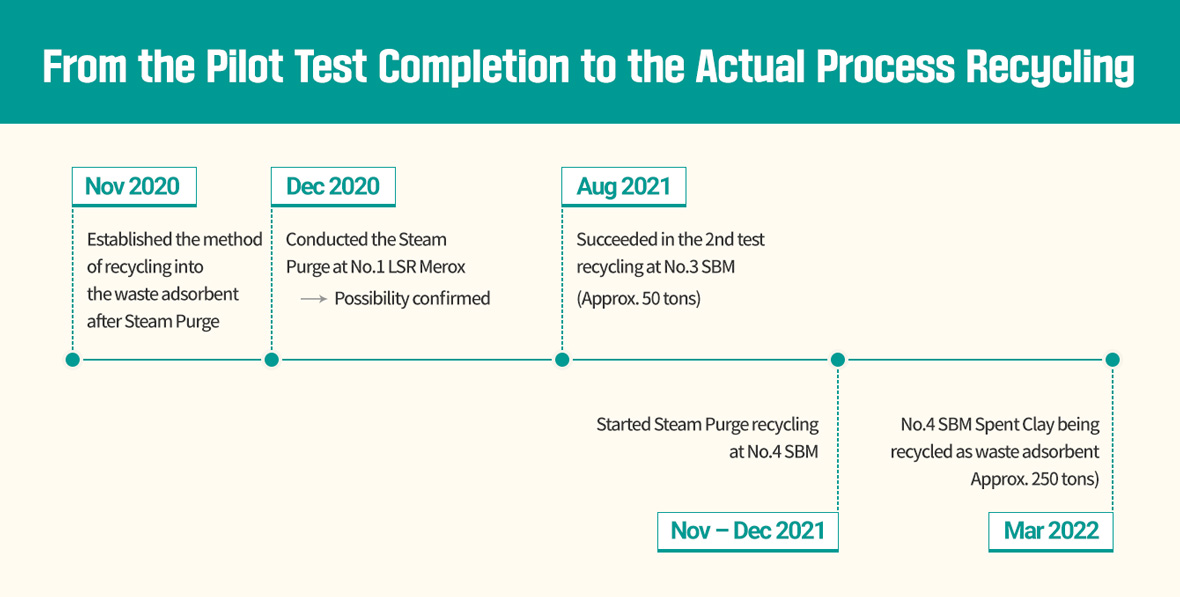

The ESG Avengers then eliminated the obstacles step by step. They made use of the No.1 LSR Merox to take pilot test in a condition similar to the actual process. About 40 tons of clay were utilized for the steam purge test, and they established the procedure simultaneously.

In this process, the remaining H/C and H2S (hydrogen sulfide) emitted out of the Spent Clay Purge Gas was 0 ppm (zero parts per million). And the second test was conducted at the No.3 SBM, the actual test, and it ended in success with over 50 tons of spent clay up for recycling.

About four months later, in November 2021, the tedious yet productive testing came to an end as the main process No.4 SBM successfully conducted the Steam Purge method and recycled the spent clay. As of March 2022, about 250 tons of spent clay have been turned into the waste adsorbents at the No.4 SBM process to be sustainably recycled into cement materials and others.

This case is a proof of how “innovating working method” can bring great results. Just with the members’ competencies, strong determination, and boldness, Ulsan CLX shows how they can achieve Zero Waste without introducing new facilities or changing raw materials.

The ESG Avengers took the courageous choice to do away with the accustomed manner of doing things and strove to achieve 0 (zero) ppm of remaining H/C. Bringing in the Steam Purge method in the clay could be interpreted as the end and beginning because each process was a flight to the future and a step forward the ESG management.

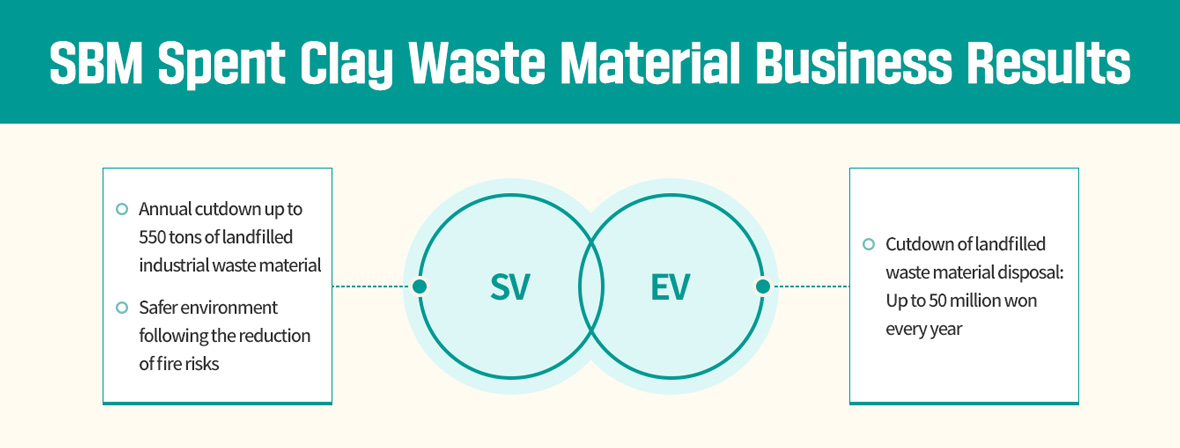

By recycling the SBM spent clay waste, Ulsan CLX succeed in creating social values and economic values at the same time. As the members strive to achieve ESG with a relentless spirit of seeking new ways and never giving up, we are looking forward to other ESG management achievements of Ulsan CLX.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin