SK Energy

SK Energy■ Commencing commercial production next month with a dedicated SAF production line using co-processing methods; utilizing bio-feedstocks such as used cooking oil and animal fat to continuously produce SAF and other low-carbon products

■ Achieved multiple certifications including ISCC CORSIA/EU/PLUS for SAF sales in June

■ Said to continue to monitor both domestic and international SAF policies and market conditions closely to explore further expansion of SAF production capabilities

On September 11 (KST), SK Energy, the largest refiner in South Korea and a subsidiary of SK Innovation, announced today the completion of the nation’s first dedicated Sustainable Aviation Fuel (SAF) production line. The new facility, which leverages advanced co-processing technology, is set to commence commercial production next month. This marks a significant milestone in the company’s ongoing efforts to lead the rapidly expanding SAF market, a burgeoning field within the refining industry.

SAF is a type of aviation biofuel with similar chemical properties to jet fuels but a smaller carbon footprint. The co-processing method-based SAF production line integrates bio-feedstocks with traditional oil production processes, allowing simultaneous production of petroleum and low-carbon products. A dedicated five-kilometer pipeline is installed to feed bio-feedstocks continuously into the oil product manufacturing process, enabling continuous SAF production.

Once commercial production starts, SK Energy will complete a value chain encompassing raw material procurement, production, and sales for the SAF business. Last year, SK Trading International, another SK Innovation subsidiary, invested in waste-based raw material suppliers to ensure a consistent supply of bio-feedstocks. Furthermore, SK Energy is collaborating with Infinium to develop e-fuel technologies that utilize green hydrogen and carbon dioxide.

In June, SK Energy achieved multiple critical certifications to support SAF production and sales, including ISCC CORSIA, which officially recognizes SAF production for the international aviation sector. The company also secured ISCC EU certification under the European Union’s Renewable Energy Directive (RED) and ISCC PLUS certification for environmentally friendly products in the voluntary market.

Starting early next year, SK Energy will supply SAF to Korean Air passenger flights, a pivotal move that aligns with the company’s broader strategy for market expansion. This initiative follows a recent event on August 30 at Incheon International Airport where SK Energy, the Ministry of Trade, Industry and Energy, the Ministry of Land, Infrastructure and Transport, Incheon International Airport Corporation, and Korean Air celebrated the commercial operation of domestically produced SAF.

The global SAF market is poised for tremendous growth. According to the International Air Transport Association (IATA), global SAF demand is projected to increase nearly 70-fold, from 240,000 tons in 2022 to 18.35 million tons by 2030. Domestically, the Korean government plans to mandate SAF blending in all international flights departing from Korea starting in 2027.

“As the first company in Korea to achieve continuous SAF production through co-processing, we are well-prepared to meet the upcoming mandatory SAF blending requirements,” said Hong Kwang-pyo, Head of Strategy Division at SK Energy. “We will continue to monitor both domestic and international SAF policies and market conditions closely to explore further expansion of our SAF production capabilities.”

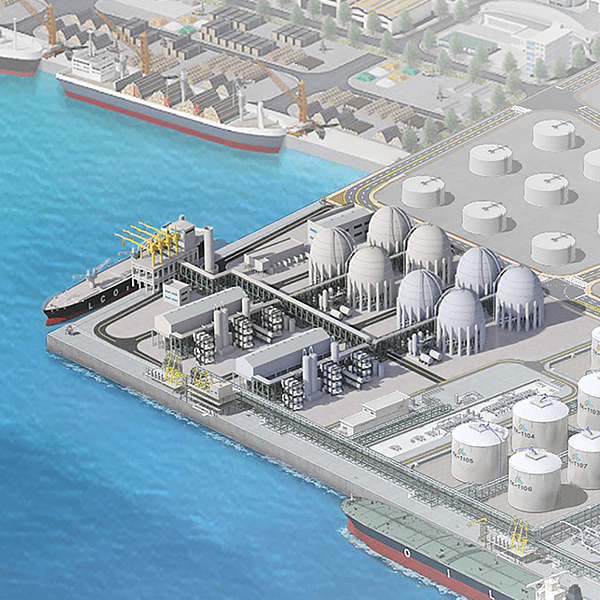

[Photo 1,2] Panoramic view of SK Energy’s facility for continuous SAF production via co-processing, using bio-feedstocks delivered through newly invested dedicated tanks and pipelines

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin