Expert Voices

Expert VoicesThe decade of the battery is just getting started

For a while, we here at Vision Mobility have been calling the 2020’s the decade of the battery. It’s taking over cars, electricity grids, home electricity storage, industrial vehicles and many other areas that weren’t considered practical just 10 years ago.

There’s also a lot of talk about what the future of the battery might look, and while to some cynical observers, the phrase “if it’s not in cell phones, it won’t be in cars for a long time” may hold true in some aspects, the reality is far more complicated.

What we are seeing is a huge expansion and diversification into the research and development of batteries into more focused applications. No longer does “one size fits all”, there will be many different options that best fit the requirements of energy density, C rate, safety, cycle life and other factors that are balanced and optimized by each design for the particular application at hand. In other words, batteries that might be optimal for phones may not be optimal for cars.

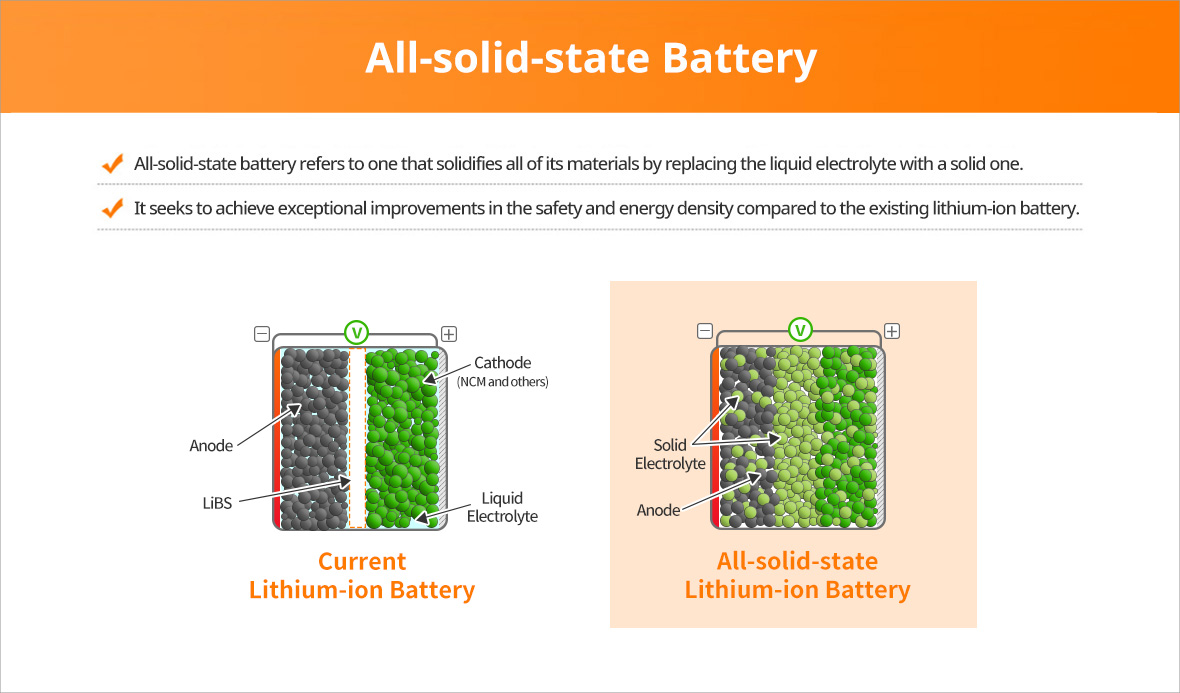

SK On (a subsidiary of SK Innovation), along with Ford and BMW, recently invested in solid state battery developer Solid Power. According to Jon Jacobs, CMO of Solid Power, solid state batteries have 3 big advantages over conventional liquid electrolyte-based batteries, which they call their “3-legged stool” value proposition: Energy Density, Safety and Calendar life benefits; the latter of which can enable cost savings and performance improvements.

The first is that energy density is significantly higher. Instead of requiring large separators between liquid cells, solid state batteries require only very thin separators to prevent a short circuit condition between the solid electrolyte layers. While this difference may be measured in microns per cell, across many thousands of cells, like in a car battery pack, it makes a big difference.

Another enabler to increased energy density is that solid state batteries can use higher silicon content anodes. Compared to graphite anodes, they have much higher energy density (as much as 10 times higher), however, they suffer degradation when working with liquid electrolytes. Using solid state electrolytes allows the silicon content to rise from 10-15% in liquid electrolyte batteries to greater than 50%, resulting in a proportionally higher energy density.

In total, this has the potential to reduce size and weight by between a third and a half of typical NCM batteries per kilowatt of storage capacity.

▲ A graphic introduction of all solid-state battery. ⓒ 2022. SK Innovation Co., Ltd. all rights reserved. This image cannot be edited.

The second is safety. Solid state electrolytes are less reactive than liquid electrolytes, which means there is less heat build up and less potential for thermal runaway. When punctured, many batteries with liquid electrolyte can create a short circuit condition, giving off energy, typically creating a fire. In this condition, most punctured solid state batteries remain much safer.

The third is improved calendar life and the potential to eliminate thermal cooling of cells. Liquid electrolyte cells don’t like being hot, and so thermal management solutions, such as active liquid cooling systems, are imperative to keep the battery within its designed operating parameters. For solid-state batteries, this is much less of a problem, which means that the requirement for expensive battery management system hardware can be reduced.

Solid state batteries do though have some disadvantages. The first is C rate, which is the maximum electricity rate the battery can charge at or produce power, is reduced versus NCM chemistry batteries. Put another way, a solid state battery has an ability to hold more energy per a given size, but its ability to take in or expend the charge at a rapid rate is worse.

The second disadvantage is cycle life, which is how many charges and discharges the battery can handle before reaching a predetermined reduction in maximum charge capacity, typically 70% to 80% of when it was new. For solid state batteries this tends to be significantly lower compared to NCM batteries and particularly vs LFP batteries. However, all batteries also degrade with time, called calendar degradation. As solid state batteries resist heat much better than NCM batteries, their application in hot climates is significantly expanded.

In other words, an NCM battery may be more suitable for a truck in Canada, which regularly sees temperatures dip below -20ºC, while in Australia, which often sees summer temperatures above 40ºC, a solid state battery may work better.

These characteristics make solid state batteries extremely important where weight, volume and safety really matters. This includes aircraft and drones especially.

However, for trucks and light vehicles you and I drive every day, the reduced weight, volume and much-improved safety from resistance to thermal runaway is also a significant factor, particularly in a large accident. It’s likely why OEMs, like Ford and BMW, have such a strong interest and have thus invested in Solid Power. For them, it offers different battery options for different vehicle use cases, and for a full range automotive manufacturer, this is an important factor.

Interestingly, the commercialization strategy that Solid Power has taken to the roll out solid state batteries is also important.

Solid Power realized that they were a small company and would always have difficulty competing with the big global battery players for production. In my discussion with Jon Jacobs, he didn’t focus so much on the technology, but the pathway to scale from lab testing a single cell, to successful demonstrating a large EV sized battery, to producing the battery in a competitive and cost-effective way.

To accomplish this, Solid Power adopted a strategy of easy manufacturability, using production processes that battery companies already use. Working jointly with SK On throughout the Research and Development phase, Solid Power has now launched its pilot plant and is on track to achieve scaled up production to OEMs by late 2022.

Through this, Solid Power then becomes one of the leading suppliers of sulfides for the electrolytes, their “secret sauce”, while companies like SK On use their commercial size to scale up production and roll out the battery onto the market. For Solid Power, this enables them to carve out a niche where they leverage their deep intellectual property, yet do not have to compete with the giants.

So, when should we expect to see solid state batteries in production vehicles? The answer also is “it depends”. Likely we’ll see them being fitted to higher end cars, where weight reduction and range is a priority. This will likely be followed by mainstream vehicles, where OEMs can leverage cost down into a more compact design. High performance sports cars, which require high current (high C rates) to extract maximum performance, may stay with NCM batteries.

While these are our forecasts in which direction solid state batteries will go, one thing I know is that the rapid pace of battery development and progress will continue in the industry through out the 2020s. It’s likely that solid state batteries will significantly improve in cycle life and maximum C rate, while NCM batteries will improve in safety and cost competitiveness, resulting in even more possibilities for new industries to electrify. One thing is for certain, the battery story has many more pages to be written this decade, and there will be several chapters about the contribution that solid state will make to our future.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin