Expert Voices

Expert Voices

There doesn’t seem to be a day go by without Vision Mobility hearing of companies developing cutting edge technology in electric transportation. While many are focused on passenger cars, there’s a huge range of both new and established firms designing and developing battery electric vehicles (EVs) for many different use cases – where there’s a vehicle, you can be sure someone is thinking about how to electrify it.

The allure of EVs in forms other than cars is no different: zero emissions at vehicle, very low operating costs and instant torque make them very desirable in many different operating environments.

However, the challenges are also similar – weight and range from lower power densities of batteries compared to liquid fuel technology mean that in some areas there is a way to go to ensure suitability, particularly where a vehicle requires light weight and/or long range. However, the proliferation of new battery technologies, ever improving power density and reduced cost opens up doors and creates new opportunities.

So, let’s explore 8 companies that are working hard to make new use cases a reality, with 4 start-ups and 4 from long standing corporations. We’ll also take a look at the types of batteries that are likely most suitable for this type of application.

| START-UP

Medium and Heavy Duty Trucks

The only truck I have ever seen that could be called ‘beautiful’ is the Astheimer designed Volta Zero, which has just commenced production. Built from the ground up as an electric truck, it is designed for urban deliveries, and features a very low cabin, almost completely enclosed by glass for awesome visibility and enhanced safety.

Of course, no future trucking conversation is complete without mentioning the Tesla Semi. Tesla has said this truck will have 500+ miles of range with an 80,000lb gross vehicle mass, and that weight will be not more than a diesel truck. It also uses Megawatt capable chargers, which is likely to enable this truck to charge to 80% in under half an hour – the typical duration of a driver rest break. These specs have the potential to transform electric trucking from low mileage, day hauling only, to long haul capable, as the charging infrastructure rolls out.

As freight and logistics is an industry that has a very wide variety of use cases, different battery types can be used, depending on the requirement. Companies seeking to carry maximum loads or drive long distances should adopt Lithium Ion (Li-ion) NMC cells (e.g. Tesla Semi) that maximise energy density and therefore offer the best possible outcome when being paid by tonne-mile.

For use cases that require less range, or aren’t likely to need full weight carrying capacity, operators should consider trucks fitted with Li-ion batteries with Iron cathode, which trades higher weight for lower cost and greater stability.

▲ Left: The Volta Zero truck by Volta Trucks / Right: The Semi truck by Tesla

(Source: Volta Trucks’s homepage, Tesla’s homepage)

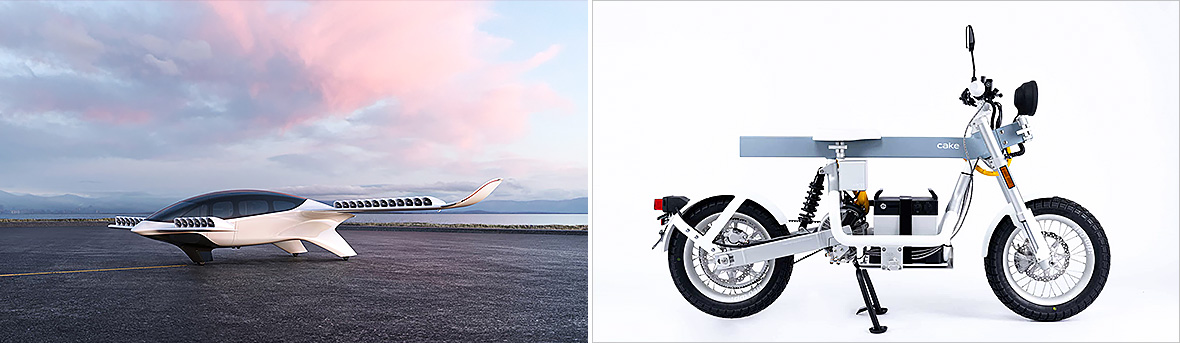

Short trip e-VTOL

The German aviation start-up Lilium has been hard at work creating a 5 to 7 electric fan jet powered VTOL aircraft. Target range is 250 kilometers with a cruise speed of 280km/h. As opposed to competitor rotor-based VTOL designs, the Lilium Jet can generate significant lift from its wings when in stable flight, adding safety, reducing noise and increasing range. Interestingly, Lilium has partnered with Swiss industrial giant and charging specialist ABB to design charging systems based around the CharIN Megawatt Charging Standard system.

e-VTOL craft need the lightest, most power dense batteries available, with Li-ion NMC cells the most obvious choice. However, it is likely that they will move to solid state batteries as the technology develops to improve power density and safety.

Motorcycles

Cake is a start-up Swedish electric motorcycle company, with a very cool industrial design look. The Makka and Osa models are targeted for both urban commuting and deliveries, while the Kalk is for recreational off-road users and racing.

These motorcycles feature exceptional off the line torque and extremely low running costs, though the purchase price point is much higher than comparable petrol powered bikes. Like other smaller vehicles, motorcycles will benefit most from lighter Li-ion NMC batteries.

▲ (Left) The Lilium Jet by Lilium / (Right) The Ösa+ electric motorbike by Cake

(Source: Lilium’s homepage, Cake’s homepage)

Recreational vehicles

Taiga Motors is a Quebec based start up OEM that will begin producing recreational vehicles, like snowmobiles and personal watercraft, (jet skis) in 2022. These vehicles are often used in environmentally sensitive areas, so reducing the pollution footprint is very important. However, the electric drive offers excellent performance, with the snowmobile capable of reaching 100 km/h in just 2.9 seconds!

The company went through a SPAC merger in early 2021 which raised over $185m to bring the vehicles to market. Such vehicles need to cram a lot of energy into a small area for decent performance and range and therefore lighter, more compact Li-ion NMC batteries are likely to be most suitable for these types of applications.

▲ The Orca electric personal watercraft (left) and the Okko electric snowmobile (right) by Taiga Motors (Source: Taiga Motor’s homepage)

| TRADITIONAL

Medium and Heavy Duty Trucks

Here in North America, the leading shuttle bus OEM by sales is Forest River Bus, a company owned by Warren Buffett’s well know investment firm Berkshire Hathaway. What sets them apart is their recent partnership with Lightning eMotors to fit electric drivetrains to the Ford F-450 bus chassis. This has enabled customers to buy new, off the shelf electric buses.

In the US, municipal transit authorities, one of the biggest purchasers of shuttle buses, are subsidized by the federal government, offsetting up to 80% of the capital cost of the bus, plus any associated equipment. Transit authorities are responsible for the remaining 20%, plus operational costs. As electric buses have a high capital cost, and low operational cost, municipalities can save tens of thousands of dollars annually by going EV.

Typically, in North America, shuttle buses are built on a medium duty truck chassis, like the Ford F450. Compared to trucks carrying freight, buses tend not to come as close to maximum load capacity, and most duty cycles are under 150 miles per day. While companies today are using Li-ion NMC batteries, the opportunity to use Li-ion Iron cathode may be appropriate for short distance applications. Buses that travel longer distances are likely to be best served with NMC chemistry batteries.

▲ The Glaval Primetime bus by Forest River

(Source: Lightning eMotors’ homepage)

Trains

Battery electric trains offer huge potential in several use cases. The first is to replace diesel power where lines are only partially electrified, and Siemens, a long-time leader in rail technology, is at the forefront of this charge. When operating with overhead electrified wires, these trains draw current to both power the train and charge the battery. When the electric line ends, the train switches to battery power. In Germany, Niederbarnimer Railway will introduce 31 new two car electric passenger trains, supplied by Siemens, in 2024; and in 2025 Amtrak will introduce 15 engines that primarily use battery electric power, but also have a diesel engine as a back up.

For freight routes, recent analysis by Nature Energy has shown that many large, long haul freight trains can be electrified by adopting dedicated large battery boxcars, with batteries as large as 14MW. This is enough to power a four engine, 100 freight car train for 240 kilometers, about the distance that many routes would typically go before requiring a stop. At this point, depleted battery box cars can be swapped out for another fully charged example.

Another opportunity with rail is to electrify shunting or switching locomotives that operate only in railway yards. When not in use, these can either be fast or slow charged, depending on upcoming requirements. Since these are typically in urban or greater urban areas, the opportunity and benefit to lower pollution is very significant.

As added weight is often an added benefit to trains, the heavier Li-ion Iron cathode batteries have great potential.

▲ Velaro Novo electric train (left) and Mireo Plus B electric train (right) produced by Siemens

(Source: Siemens’ homepage)

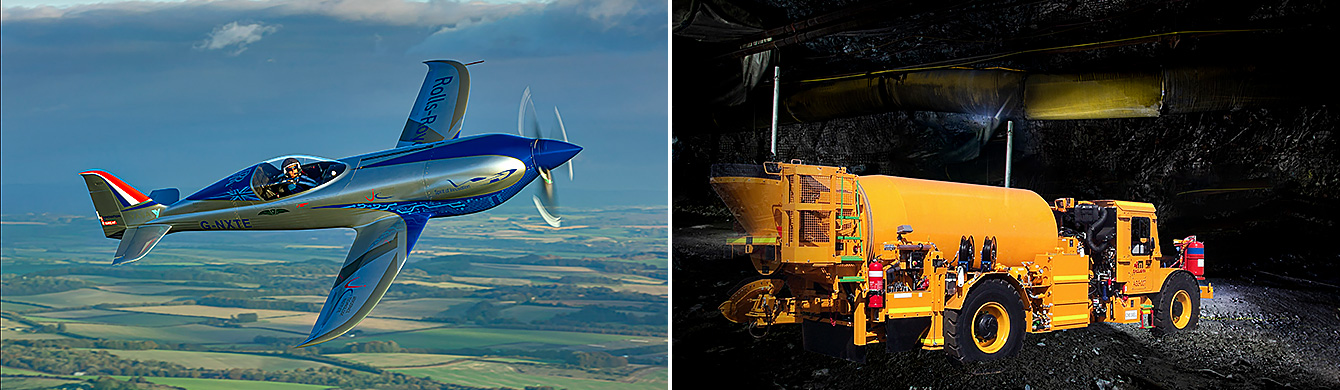

Aviation

Rolls-Royce has been a company associated with cutting edge aviation for nearly a century. Famously, many of the Allied planes during World War Two, from fighters through to bombers, were powered by Rolls-Royce Merlin V12 aero engines.

Today, Rolls-Royce is on the cutting edge of clean aviation with its Spirit of Innovation experimental electric aeroplane. This plane has just set electric aero records for top speed and climb performance of electric aircraft – with numbers right around the similarly sized Rolls-Royce powered warbird fighters like the Spitfire and P51 Mustang.

Just like e-VTOL, aircrafts need the lightest, most power dense batteries available. Again, Lithium Ion NMC cells are used today, with a movement towards solid state batteries down the road.

Mining Equipment

MacLean Engineering, based in Collingwood, Canada, has been making industrial machines for underground mining operations for nearly 50 years. In the past, underground mines have needed exceptionally large ventilation systems for diesel vehicles to operate in enclosed conditions, sometimes miles below the surface. By electrifying vehicles, mines can reduce the size of their ventilation systems by up to 90%, generating huge cost savings. This is a use case where adopting EVs greatly reduces the cost of infrastructure outside of the vehicle, and it’s a key reason why mining operations are at the forefront of the EV revolution.

As weight is typically not an issue in mining applications, Li-ion batteries with Iron cathode, will likely best balance cost and performance in these applications, while battery swapping is also a technology which is currently being used in this industry.

▲ (Left) The electric aircraft “Spirit of Innovation” by Rolls Royce / (Right) Mine-Mate™ AG3 EV Agitato by MacLean Engineering

(Source: Rolls Royce’s homepage, MacLean Engineering’s homepage)

| What does all this mean?

What is really apparent is that the “Electrify Everything!” mandate is spreading to almost every transportation application that one can think of. The promise of zero emissions, high torque and low operating costs make for a compelling business case in almost all applications. Not only do vehicles cost less to run, they often do the job much better.

As Li-ion battery technology continues to improve, and new chemistries target specific niches, more opportunities are opened up. Applications that were seen as difficult 5 years ago are today being researched and trialled in depth.

An interesting factor is that this progress is not just centred around new start-ups. Long established companies also understand that their future is in battery electric vehicle (BEV) and are making heavy investments in bringing products to market. For Siemens, Forest River Bus, Rolls-Royce and MacLean Engineering, this means electrifying a transportation business that they are already experts in.

For new companies, opportunities to establish a foothold in well established markets is rare. The electrification of transportation is a disruption that many are taking advantage of, no doubt motivated by the extraordinary success of Tesla, and relatively slow-moving incumbents.

As stricter government mandates, changing consumer preference and stronger company ESG policies accelerate the shift to vehicle electrification, the opportunity for any battery supplier with strong product and safety track record, like SK On (a subsidiary of SK Innovation), is immense.

The Head of SK On’s Cell Development Center, Lee Jon-ha, added some further comments, “SK On are experts NCM technology that is currently leading the battery industry through continuous R&D. We are the first in the world to have successfully developed NCM6, NCM8, and most recently the NCM9 battery, which will be mass supplied to Ford’s F-150 Lightning model next year. While SK On continues to develop NCM technology to gain a competitive edge in the market, in the near future we will introduce a more diversified product portfolio with more advanced batteries that can be used in various types of vehicles.”

Just like the best internet companies of 10 years ago, the best battery companies are on track to become economic powerhouses as they provide the energy for our global transportation needs in almost every use case you can think of. What that means is a cleaner environment aligns with an economic opportunity that we haven’t seen in transportation for over 100 years, and that’s something to be very excited about.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin