Press Releases

Press Releases■ Cooperates with Professor Lee Seung-woo, whose thesis was introduced in the world-renowned academic journal, ‘Nature,’ on January 13, 2022

– Solid electrolyte with excellent ionic conductivity and elasticity, which secures both performance and safety

■ SK Innovation accelerates the development of all-solid-state-batteries backed by the cooperation with Nobel Prize Winner Professor Goodenough, and Solid Power

■ Lee Seong-jun, head of the Institute of Environmental Science and Technology, said, “We will move up the era of all-solid-state-batteries, which are also called ‘dream batteries’, by cooperating with Professor Lee Seung-woo’s research team who achieved a remarkable research result to build up our technological competitiveness and contribute to a greater convenience for humanity”

On January 16 (KST), 2022, SK Innovation disclosed that it had committed to collaborating with a research team led by Professor Lee Seung-woo of Georgia Tech in the United States to advance the era of next-generation all-solid-state batteries.

All-solid-state battery is a battery that uses solid electrolyte instead of the liquid electrolyte that is currently used. It is in the spotlight as a future battery since it has the potential to dramatically reduce the weight, volume, and risk of fire while increasing battery capacity. It is called a ‘dream battery’ because there are still many challenges to overcome until development, but SK Innovation and Professor Lee’s research team have established a cooperative system in the all-solid-state-battery field, which can be a ‘game changer’ in the EV market.

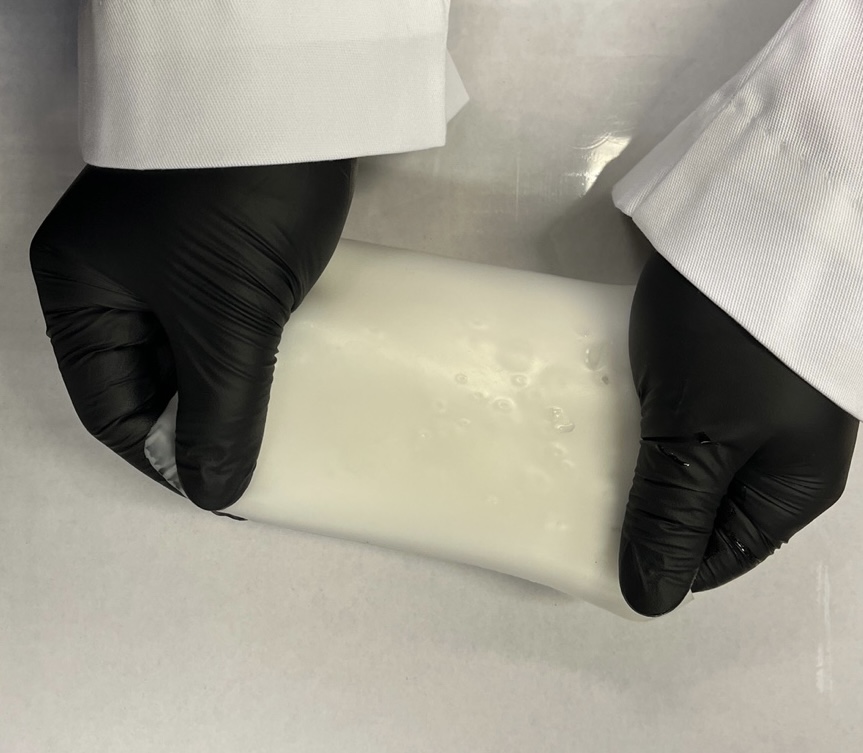

Professor Lee Seung-woo is a great scholar in the field whose thesis was introduced in the world-renowned academic journal, ‘Nature’ on January 13 (local time), 2022, for his pioneering rubber-type high polymer solid electrolyte developed jointly with KAIST.

The solid electrolyte developed by Professor Lee boosts the ionic conductivity 100 times, which was considered a drawback of the existing solid electrolyte while securing rubber-like elasticity and being operable at room temperature. The ionic conductivity refers to how well ions can move inside a battery.

If the ionic conductivity is increased, lithium ions can be rapidly transferred inside the battery, which results in better battery performance. Furthermore, the great elasticity of solid electrolytes contributes to securing safety since it protects the electrolyte from dendrites, a phenomenon in which lithium forms inside the battery cell in the shape of sharp-ended tree branches.

Realizing a solid electrolyte that simultaneously ensures ionic conductivity and safety while functioning at room temperature has been regarded as the most demanding challenge, Professor Lee’s solid electrolyte is evaluated as a groundbreaking achievement. If the technology is introduced, it is expected that the driving range of an electronic vehicle, which is currently about 500km, will be enhanced by 800km on a single charge.

SK Innovation expects to accelerate the development of all-solid-state batteries by adding the existing all-solid-state battery technology that it has independently secured and Professor Lee’s research results.

SK Innovation is not only conducting its own research but putting efforts to develop all-solid-state batteries actively cooperating with various groups. Last October, it has started to work with Solid Power, USA, to develop all-solid-state batteries that can be made in the current lithium-ion battery production facilities. Since 2020, it has been working in collaboration with the Nobel laureate Professor John B. Goodenough.

Lee Seong-jun, Head of SK Innovation’s Institute of Environmental Science and Technology, said, “In collaboration with Professor Lee Seung-woo’s research team who achieved a remarkable research result, we will move up the era of all-solid-state-batteries, which are also called ‘dream batteries’ to build up our technological competitiveness while contributing to a greater convenience for humanity.”

[Photo]

A researcher stretches the large-scale rubber material. (Photo credit: Georgia Tech)

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin