SK Geo Centric

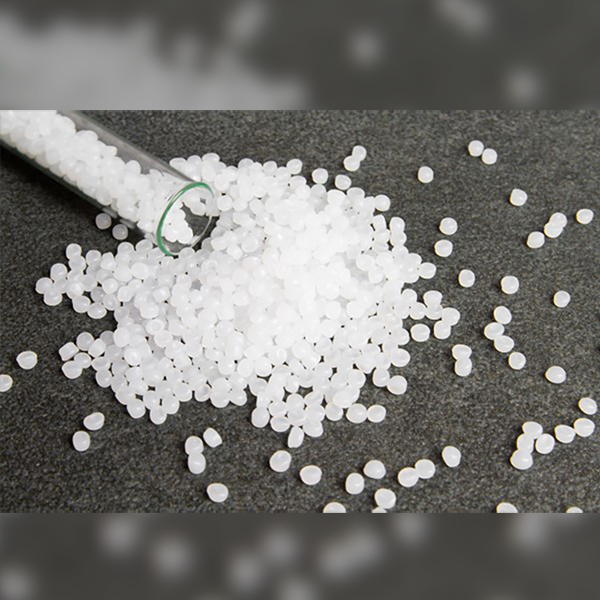

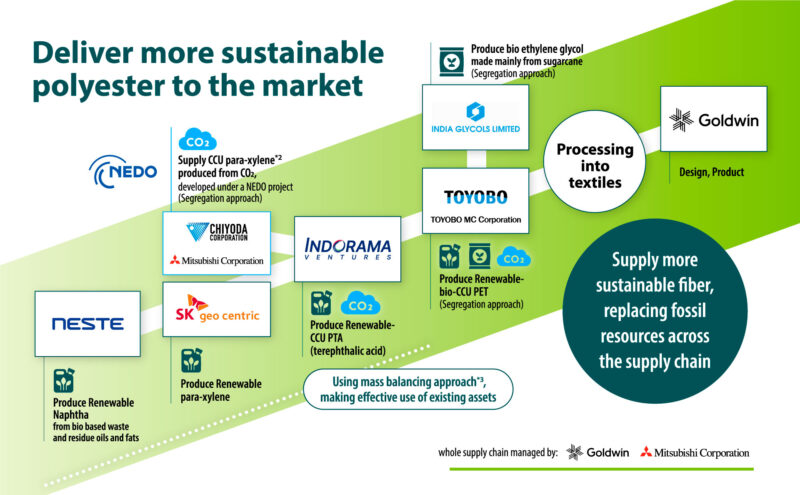

SK Geo CentricA consortium of seven companies across five countries has jointly established a supply chain for more sustainable polyester fiber. Instead of fossil materials, renewable and bio-based materials as well as materials produced via carbon capture and utilization (CCU para-xylene)** will be used in the manufacturing of polyester fibers for THE NORTH FACE brand in Japan. The project parties are Goldwin, in the role of the Project Owner, Mitsubishi Corporation, Chiyoda Corporation (all three from Japan), SK Geo Centric (South Korea), Indorama Ventures (Thailand), India Glycols (India) and Neste (Finland).

The polyester fiber produced from the project is planned to be used by Goldwin for a part of THE NORTH FACE products including sports uniforms in July 2024. After that, the launch of further products and brands of Goldwin will be considered.

The seven companies apply a mass balancing approach*** to ensure credible traceability of material streams throughout the supply chain and will jointly continue to proactively promote the de-fossilization of materials to contribute to a more sustainable society.

“This consortium has great significance as it is the first case where multiple companies gather under the same of reducing carbon by making sustainable polyester that will eventually be used in clothing products in the final stage,” said an official from SK Geo Centric. “This is just the beginning. We will strive to keep creating greater synergy through cooperation with global companies.”

*World’s first: This refers to the first time CCU para-xylene (direct synthesis from CO) is applied and also to the first time a polyester is made without the use of fossil materials in collaboration among upstream material companies and a downstream apparel company through mass balancing, according to the companies’ research.

**CCU para-xylene: Regarding the production of para-xylene derived from CO2 as a raw material, the University of Toyama, HighChem Company Limited, Nippon Steel Engineering Co. Ltd., Nippon Steel Corporation, Chiyoda Corporation and Mitsubishi Corporation were awarded in 2020 as a NEDO‘s project (New Energy and Industrial Technology Development Organization) “Technology Development for Carbon Recycling and Next Generation Thermal Power Generation/Technology Development for CO2 Emission Reduction and Effective Utilization” and are conducting the joint research and development. This project is to supply CO2-derived para-xylene as a trial, which was produced during the operation process of a pilot plant installed in Chiyoda Corporation’s Koyasu Research Park since March 2022.

***Mass balance / Mass balancing approach: A process that tracks the amount and sustainability characteristics of materials and enables allocation of such to a specific portion of the product in proportion to the input of the raw materials with sustainability characteristics, when they are mixed with other materials in the process of manufacturing and distribution of products.

[Photo] The establishment of a sustainable polyester supply chain by the consortium formed by SK Geo Centric in collaboration with global petrochemical, fiber, and clothing companies

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin