SK On

SK On■ SK On joined a quadrilateral MOU with KESCO, SK Eco Plant, and KD Power

■ To operate and verify temporary power at the construction site using an ESS built with recycled batteries

■ To construct a BaaS model for an eco-friendly virtuous cycle of resources that will expand the ecosystem while lowering electricity prices

SK On is devoted to creating an “eco-friendly ESS” by repurposing EV batteries. On Nov. 29, 2021, SK On signed a quadrilateral MOU with the Korea Electrical Safety Corporation (KESCO), SK Eco Plant, KD Power Co., Ltd. in SK Seorin Building, Jongno-gu, Seoul to develop an energy storage system (ESS) in a construction site.

SK On will build an ESS with scrapped electric vehicle batteries in collaboration with KD Power, and SK Eco Plant will install it in a temporary power facility at Anyang apartment complex in Gyeonggi-do where SK Eco Plant is constructing for the next two years, and jointly operate the ESS with SK On to verify its applicability. KESCO will monitor the safety of recycled ESS on a regular basis and create relevant technological standards to encourage ESS manufacturers to employ recycled batteries.

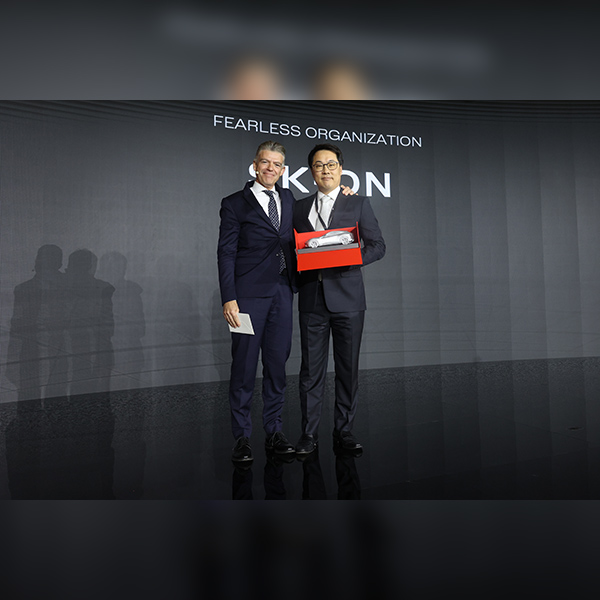

The MOU ceremony was attended by Head of KESCO’s Renewable Safety Division Ki Han-sang, Project Director of SK Eco Plant’s Ecospace Project Lee Tae-hee, CEO of KD Power Lee Yang-soo, Head of SK On’s E-Mobility Office Sohn Hawk, among others.

SK On and SK Eco Plant agreed that an ESS made of recycled batteries would not only contribute to an environmentally friendly virtuous resource cycle, but would also be useful on a construction site where the electricity bill is high and the Peak Electricity Time Zone System, which imposes a surcharge for temporary high electricity loads, is in effect.

The Korean Ministry of Trade, Industry, and Energy has granted SK On and SK Eco Plant a regulation special case clearance for an ESS utilizing used batteries, allowing them to conduct a trial ESS.

During the test period, SK On will gather and analyze real-time ESS operation data alongside the other three partners in order to verify its performance and safety features. Its goal is to build the framework for a BaaS (Battery as a Service) business model based on ESS from recycled batteries.

This activity demonstrates SK On’s endeavor to realize Carbon to Green strategy, which was announced by its mother company SK Innovation earlier this year to take shift from traditional petrochemical-centered portfolio to eco-friendly energy. Moreover, since it is built from batteries gathered from abandoned cars, the recycled ESS is projected to generate differentiated eco-friendly qualities from conventional ESS.

“This quadrilateral cooperation allows us to establish a BaaS model in the battery recycling business sector where eco-friendly values can be gathered from a virtuous cycle of resources,” said Sohn Hawk, Head of E-Mobility Office, SK On. “Next year, we will undertake various eco-friendly ESS oriented pilot services with global partners as well,” he added.

[Photos] From left: Head of KESCO’s Renewable Safety Division Ki Han-sang, Head of SK On’s E-Mobility Office Sohn Hawk, Project Director of SK Eco Plant’s Ecospace Project Lee Tae-hee, and CEO of KD Power Lee Yang-soo take commemorative photos after the MOU signing ceremony at SK Seorin Building, Seoul, Korea, on November 29, 2021.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin