SK Geo Centric

SK Geo Centric– The rise of sustainable fashion, a.k.a. “conscious fashion” 👀

– Turning waste plastic into clothing? SK Geo Centric’s PET depolymerization technology 👕👖

– The world’s first plastic recycling cluster, SK Geo Centric’s Ulsan ARC 👍

As the weather becomes much colder during this winter season, the fashion choices of consumers are becoming thicker, warmer, and cozier.

Fashion is almost as important as food in our daily lives. It’s a topic that’s always at the center of attention, no matter the season. Padded jackets and boots are the undisputed must haves in the fall/winter seasons, while the “old money look” becomes a new trend as it gives off that neat and classy look without having to splurge on flashy clothes.

However, the underdog in the fashion industry that is worth noting is sustainable fashion. Also known as “conscious fashion,” the trend emerged as a mainstay of the fashion industry in opposition to fast fashion, which has been cited as a cause of environmental pollution. Conscious fashion is a compound word of conscious, which means doing or acting with critical awareness, and fashion. It is usually referred to the consumer trend of products being produced ethically and eco-consciously throughout the entire process, including clothing materials, manufacturing process, transportation, and storage.

In line with this, clothing brands domestically and abroad, are also introducing clothing that are produced with eco-friendly plastic fibers. For example, waste PET bottles are being broken down to make clothing and marine waste is collected and upcycled to make clothing. But how is it possible to turn waste plastic into clothes?

The answer can be found in advanced recycling*. Advanced recycling is a technology that turns waste plastic into its pure raw material state. It is superior to the level of general plastic products compared to mechanical recycling, which consists of crushing, washing, and then melting plastic with a machine. In addition, it is expected that advanced recycling will substantially expand as it provides a fundamental solution to the waste plastic pollution issue as it enables repeated recycling.

(*)Three key advanced recycling technologies for waste plastic: pyrolysis, high-purity polypropylene (PP) extraction, and depolymerization.

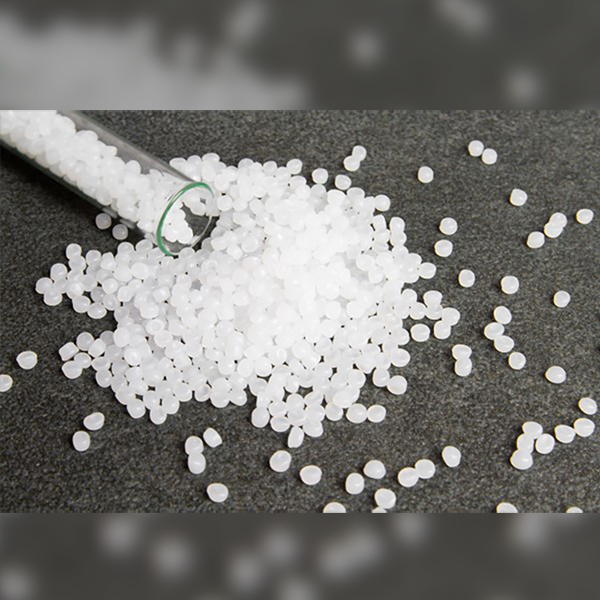

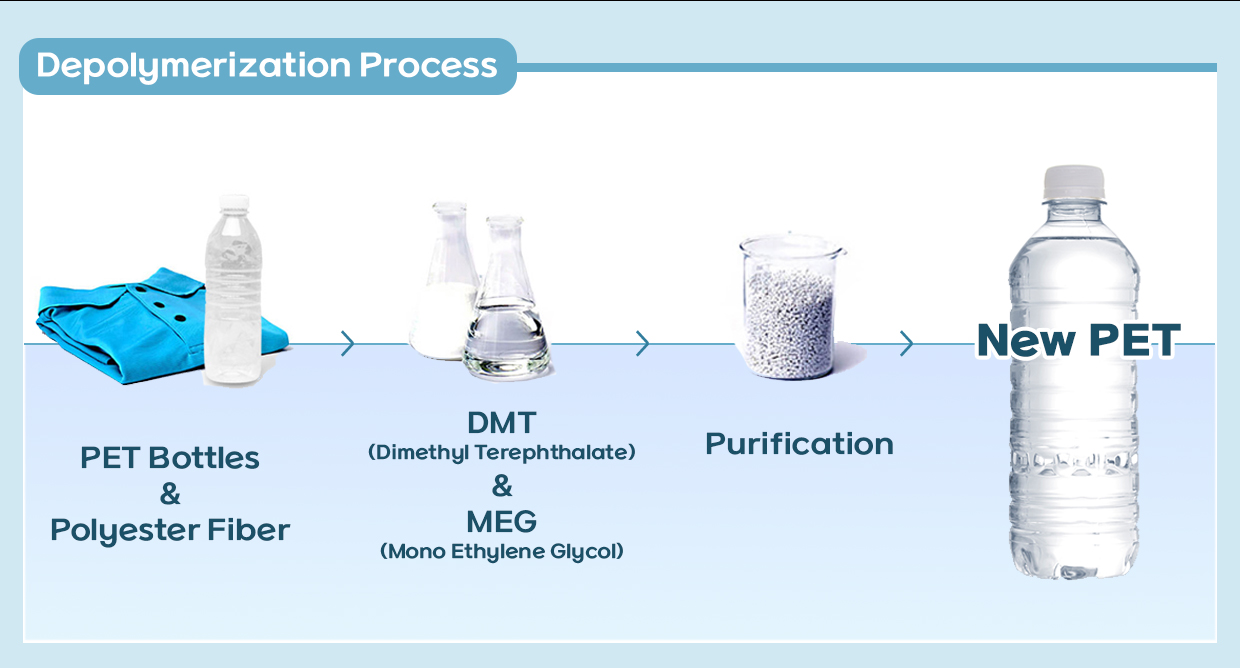

PET depolymerization technology, also called the “flower of advanced recycling,” dismantles polymerized PET polymers, turns them back into raw materials, and recombines them to create high quality PET. As for colored PET bottles, polyester (PE) fibers, etc., they are first treated, placed into a reactor, crushed into small pieces, and made transparent (purified) through a multiple-step process to produce PET that is comparable to pure PET extracted from crude oil.

To secure this depolymerization technology, SK Geo Centric, a subsidiary of SK Innovation, made an equity investment in Loop Industries, a Canadian company that focuses on innovative waste PET bottle/waste fiber recycling technology, in 2021 and acquired exclusive rights in the Asian region.

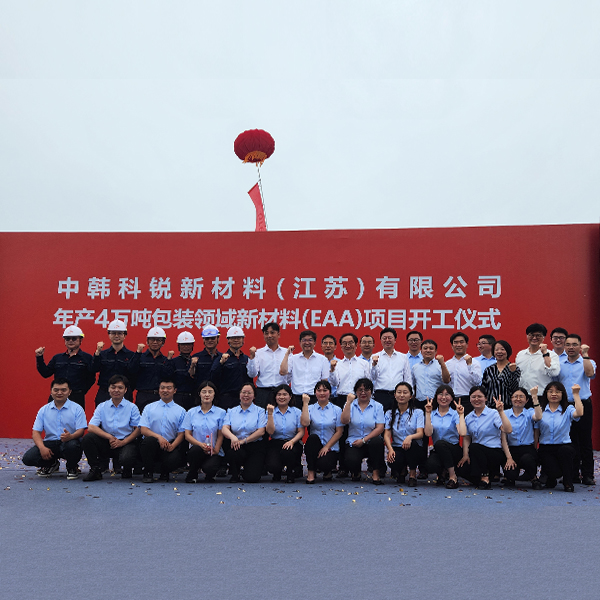

SK Geo Centric held a groundbreaking ceremony to celebrate the Ulsan ARC at the SK Innovation Ulsan Complex on November 15 (local time).

On November 15 of this year, SK Geo Centric held a groundbreaking ceremony to celebrate the establishment of the world’s first plastic recycling cluster, Ulsan ARC (Advanced Recycling Cluster), located within the 215,000 ㎡ area of SK Innovation’s refining and petrochemical complex “Ulsan CLX” in Nam-gu, Ulsan, South Korea. The complex is equivalent to the size of about 22 international standard soccer fields, with 320,000 tons of waste plastic to be recycled every year from 2026 when the Ulsan ARC commercial production begins in earnest after completion. This amounts to approximately 10% of waste plastic (3.5 million tons) that is incinerated or landfilled in Korea every year.

Asia is a global manufacturing hub and is one of the largest producing regions for PET and polyester fibers. In particular, sports clothing, sewing fabric, and banners made of polyester are difficult to recycle, so most of them are incinerated or end up in the landfill. Through SK Geo Centric’s advanced recycling technology, polyester fibers can also be recycled, and is expected to contribute as a solution to solving the global waste plastic problem in addition to reducing waste from clothing production.

SK Geo Centric will not only lead the plastic circular economy through the Ulsan ARC, but it will also do its best to achieve its goal of becoming the world’s best recycling material company.

Via the video below, let’s take closer look at the era of infinite waste plastic resources SK Geo Centric dreams of.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin