SK Geo Centric

SK Geo Centric

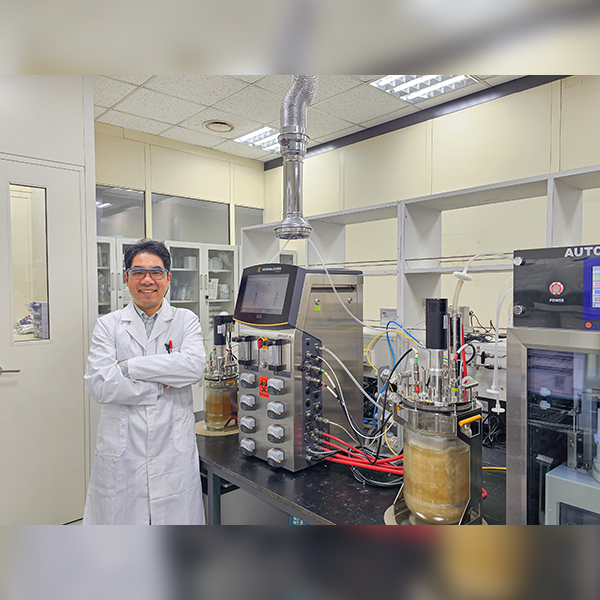

▲ Park So-young, Leader of Packaging Green Solution Squad, Packaging Division, SK Geo Centric

SK Geo Centric has recently launched an ice pack made up of recycled resin through joint development with “Market Kurly”, a Korean online shopping mall for fresh food distribution, which is famous for early morning delivery, for environmentally-friendly packaging materials. With the introduction of the recycled resin ice pack, which marks the first of its kind in the e-commerce industry, SK Geo Centric and Market Kurly expect that it will save 104 tons of plastic packaging and 230 tons of CO2 generated in the production of those by the end of this year. It brings about the same effect as planting 82,800 saplings of pine trees.

We invited Park So-young, Leader of Packaging Green Solution Squad, Packaging Division, SK Geo Centric, to learn about SK Geo Centric’s heartfelt dedication, including the collaboration with Market Kurly, to creating an ecosystem for a virtuous resource cycle.

▲(Left) Eco-friendly ice pack using a recycled resin, jointly developed by Market Kurly and SK Geo Centric / (Right) Existing ice pack (right) & The eco-friendly ice pack using a recycled resin jointly developed by Market Kurly and SK Geo Centric (left)

Q1. As the waste plastic crisis worsened, SK Geo Centric took the lead in building the circular economy for plastics by collaborating with Market Kurly to jointly develop recycled resin-based ice packs to reduce plastic wastes. Could you please go into further detail about this?

Following the COVID-19, there has been a significant increase in the volume of plastic waste. While recycling rates are increasing every year, the actual recycling rate that leads to practical recycling remains low. In other words, the rate of recycling plastics that turns into raw materials or resources is expected to be 12 percent at most, which is significantly lower than the rates of recycling of papers, steel, glass, and other materials.

SK Geo Centric is spurring to push forward with its 3R(Reduce/Replace/Recycle) solution product development with various stakeholders in order to implement its “Plastic Wastes & Carbon Zero” strategy, and we also consider methods to boost the plastic recycling rates.

As a part of its 3R efforts, SK Geo Centric has been conducting a collaboration project to develop eco-friendly subsidiary materials since 2019. In terms of ice packs, after a year and a half of our efforts, the company commercialized and released the product in 2020 by changing the difficult-to-recycle materials into a mono-PE(Polyethylene) material while introducing ice packs made from plastic wastes to the market in April of this year. It is an environmentally friendly ice pack packaging material composed of recycled resin that can be recycled for a virtuous resource cycle. Furthermore, by expanding the use of the mono-PE material, SK Geo Centric launched a commercialized packaging material for a refill product of Aekyung Industrial’s detergent brand “Spark.” Concerning the recycled resin, SK Geo Centric’s Packaging Division is also aggressively seeking to upcycle plastic wastes that were previously used for low-value-added purposes and explore more diverse uses such as detergent containers, bags made of alternatives to faux leather, and external packaging, as well as commercialize and launch these products.

Q2. According to what I’ve heard, the ice pack co-oped/developed with Market Kurly is formed of a mono-material packaging. What distinguishes it from existing packing materials, and what are its strengths?

While most packaging materials are quite thin, they are composed of a variety of composite materials to perform diverse functions. PET film for printing, nylon film to endure exterior shocks, and PE film to enhance concealment are all glued together, and they are typically incinerated since they are difficult to be separated from one another in a plastic waste stream. Therefore, the composite-material packaging makes recycling nearly impossible. The mono-PE material produced by SK Geo Centric, on the other hand, encompasses all of the characteristics of other materials as PE properties by combining a variety of PEs ranging from ultra-low density to high density. As the ice pack’s packaging is changed to the mono-PE one, its PE film becomes softer compared to the PET film, which was previously used for the external layer of the composite material. Therefore, it enables less friction coefficient and enhances the leaking issue of the ice pack. Since Market Kurly’s ice packs are made of the mono-material packaging, they can be recycled, and if it earns a higher separation& disposal class in the future, it will result in tax savings once the EPR(Extended Producer Responsibility) system becomes enhanced.

Q3. Are there any more SK Geo Centric’s examples of converting old packaging materials to the mono-material ones, so contributing to a virtuous resource cycle?

Our first product commercialized and released on the market was the container of SK Lubricants’ SK ZIC ZERO. Originally, the container was made out multiple materials, including an HDPE (High Density Polyethylene) container, a PP (Polypropylene) lid, a PP label, and an AI and paper stopper. All parts were converted to the mono-PE material. At the same time, recycled lubricant containers were used for manufacturing new ones. This container was commercially released in 2020. SK Geo Centric had a successful launch of its products in the areas of industrial containers and e-commerce. In order to further expand to various fields, with the successful mono-PE material in our hand, we collaborated with Aekyung Industrial, the daily supplies company.

The refill product of Aekyung Industrial’s flagship detergent brand “Spark” uses composite materials for packaging, and as its PET film is transparent and glossy, it is aesthetically more appealing. Moreover, the mono-PE material enhanced the product’s recyclability, and, at the same time, SK Geo Centric worked on improving the transparency of the PE material. Therefore, the mono-PE material could have similar properties to existing packaging materials. To improve the concealment of Spark, our company cooperated with Aekyung Industrial and DL Chemical for various tests, including a drop test, and various film production. After two years of endeavor for the research and development, this March, the packaging material was commercially introduced to Spark’s refill product packaging.

Other than this case, SK Geo Centric strives to actively research and develop products to make success cases for the virtuous resource circle in various fields inside and outside Korea.

▲(Left) SK Lubricants’ “SK ZIC ZERO” in the mono-material container developed/produced by SK Geo Centric / (Right) Aekyung Industrial’s “Spark” that adopted the mono-material packaging developed/produced by SK Geo Centric

Q4. Is there any memorable episode while you were in charge of the mono-material development?

There was a point in the early stages of eco-friendly ice pack material development when SK Geo Centric’s mono-material PE development was put on pause for a while due to the temporary popularity of paper ice packs caused by the plastic waste issue. Fortunately, it was soon widely recognized that, while a paper ice pack was covered by paper, its material was actually made out of plastic, so it was required to be separated as “plastic packaging- OTHER,” which is difficult to recycle; as a result, the mono-PE development was put back on track, and we eventually released our product on the market. Also, I’d like to take this opportunity to express my deepest gratitude once again to Hong Dae-sig, Leader of the MR PE Sourcing Squad, Packaging Division, SK Geo Centric for leading and carrying out the overall project for the rapid commercialization of the mono-material products, researchers who devoted themselves to analysis and film structure development, and DL Chemical for manufacturing film samples day and night.

Q5. Aside from the mono-material packaging projects such as Market Kurly and Spark that you’ve mentioned earlier, is there any other project on eco-friendly material development SK Geo Centric is pushing forward in and out of Korea?

We have commercialized the mono-PE material packaging for pet food products, and we are working with various brand owners to apply the mono-PE material to diverse food products and daily supplies. For another axis for the virtuous resource circle, which is to solve the waste plastic issue, we are pushing forward with recycling waste plastics and transforming them into new plastic materials (Stretch Wrap Closed Loop), and we have undertaken a pilot production in collaboration with one of Korea’s major retailers. In addition, we are also on a task to utilize plastic containers generated from our daily activities and apply them to daily supplies. Furthermore, we cooperate with MONTSENU, an upcycling social venture incubated and supported by SK Innovation, to produce environmentally friendly bags made from waste plastic bags rather than faux leathers.

▲ Park So-young, Leader of Packaging Green Solution Squad, Packaging Division, SK Geo Centric

Q6. Finally, what is the ultimate goal of SK Geo Centric for developing environmentally-friendly materials such as the mono-material?

SK Geo Centric is working on several projects with SK Innovations’ Institute of Environmental Science & Technology to provide diverse stakeholders with a total solution for the virtuous resource cycle system that includes the development of recyclable materials for a virtuous cycle system for plastics, the development of the use of waste plastics, improved recycling rates, the replacement of harmful substances, the reduction of the amount of polymer used, and more. SK Geo Centric is making a concerted effort to reach Net-Zero while also providing stakeholders with carbon reduction values. We will not be satisfied with these objectives and will strive to achieve greater synergy by integrating SK Geo Centric’s high performance-products with eco-friendly materials.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin