SK Geo Centric

SK Geo Centric■ SK Global Chemical joins a partnership to establish a joint venture (JV) with PureCycle Technologies for recycling PP waste

– To partner in building a plant that has the technology that can extract pure PP from synthetic plastics by injecting solvent

■ The construction of the JV plant will follow execution of the JV Agreement, and is expected to start at the end of 2022 to treat 50,000 tons of PP per year, ready for commercial operation from 2025

■ Following execution of this JV with PureCycle, SK Global Chemical will have access to recycle plastic waste with three major chemical recycling technologies: solvent extraction, pyrolysis, and depolymerization

■ CEO of SK Global Chemical Na Kyung-soo says the company will create a virtuous cycle of plastic to break new ground as a green chemical company

On August 12th, SK Global Chemical announced that it has signed an MOU with PureCycle Technologies, Inc., a U.S. waste plastic recycling company, to establish a joint venture (JV).

PureCycle Technologies (PureCycle) is a leading company in recycling polypropylene (PP), a type of plastic widely used for containers and car interiors. Until now, it was challenging to recycle PP as it is made of different materials and additives.

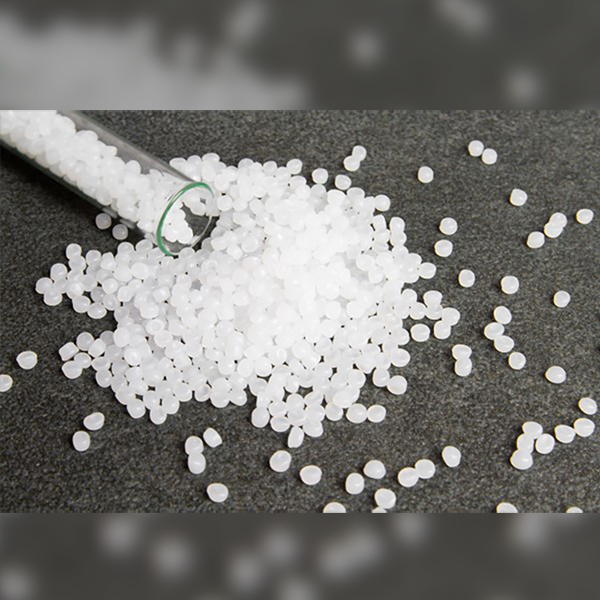

PureCycle solved this problem with a solvent extraction technology, injecting solvent into the plastic waste to dissolve and only extract the PP. This enables the recycling of contaminated food containers, colored plastics, and car interior materials like dashboards made of composite materials.

SK Global Chemical plans to establish a JV with PureCycle and start the JV plant’s construction in South Korea at the end of 2022, and be ready for commercial operation by 2025. According to this plan, the JV plant will process about 50,000 tons of PP plastic waste annually to obtain PP, which was previously only produced through chemical processes, from the waste. In addition, SK Global Chemical plans for the JV to expand the processing capability of the plant.

The high-purity PP extracted through this process will be re-used for manufacturing various PP products. This creates a virtuous cycle of plastic by utilizing plastic waste for plastic manufacturing and prevents further environmental pollution.

SK Global Chemical has its own technological competitiveness, particularly in producing high-value-added materials such as high-stiffness PP, which is widely used as lightweight car interior material. Accordingly, the company expects that recycled PP obtained through this partnership with PureCycle will be used to manufacture automobile parts later. SK Global Chemical believes making products with eco-friendly materials will secure higher competitiveness in the future as it will comply with the growingly strict environmental regulations.

In addition to ▲ pyrolysis technology that obtains raw materials such as naphtha by applying heat to waste vinyl, and ▲ depolymerization technology that chemically decomposes and recycles contaminated waste PET plastic and polyester fiber, this partnership with PureCycle will bring the last piece of the puzzle for SK Global Chemical to complete its “three major advanced recycling technologies”.

Advanced recycling significantly improves environmental problems by recycling plastic waste that had previously been merely incinerated or landfilled. These technologies overcome the limitations of physical recycling, which cannot recycle plastic waste if it is mixed with contaminated or colored plastic because it is only a method of crushing plastic waste.

SK Global Chemical announced its future vision, the company declared that it would use these technology to recycle plastic waste that exceeds the total amount of plastic it produces in a year. One of the company’s actions to reach this target is to invest about KRW 600 billion by 2025 to build a pyrolysis and depolymerization plant on a site of approximately 160,000 square meters in Ulsan Mipo National Industrial Complex. Once completed, this will be biggest plastic waste recycling project in South Korea.

Mike Otworth, CEO of PureCycle, said, “Partnering with the leading recycling waste company in South Korea is a major milestone for PureCycle. We are bringing together a premier team of experts to achieve our goal of recycling one billion pounds of polypropylene waste by 2025. The sad reality is that 91% of plastic waste is not recycled. That is exactly why our work with SK Global Chemical will be incredibly important to reducing plastic waste and helping society view plastic as an infinitely sustainable material.”

CEO of SK Global Chemical Na Kyung-soo said, “The partnership with PureCycle shows our deep commitment to creating a circular economy for plastics and shows that we can collaborate globally to solve plastic waste problem. We are focused on leading circular systems for plastics with top-notch technology, and that is why PureCycle is the perfect partner for us to continue this focus and amplify our goals.” “We will create a virtuous cycle of plastic to break new ground as a green chemical company,” he added.

[Photo]

CEO of SK Global Chemical Na Kyung-soo (left) takes photos with Mike Otworth, CEO of PureCycle Technologies, after signing the MOU through video conference on August 12th (KST).

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin