SK Geo Centric

SK Geo CentricSK Geo Centric will combine efforts with the domestic pyrolysis company to reach its goal of being the world’s largest urban oil field corporation based on plastic waste recycling.

SK Geo Centric disclosed its heart of green transformation, SK Innovation Institute of Environmental Science & Technology, and a factory that adopts pyrolysis oil technology of Eco Creation, a partner of the company.

SK Geo Centric has made a new start in September under a new corporate name signifying eco-friendly innovation centered on the earth and shared the financial story, revolving around the evolution to become the world’s largest eco-friendly urban oil field company that extracts oils from recycling plastic wastes.

Especially, the cooperation among three partners: Eco Creation, a South Korean company specializing in pyrolysis; SK Geo Centric, which is equipped with know-hows from its traditional chemical business; and SK Innovation’s Institute of Environmental Science & Technology, drew particular attention in that it will make a significant contribution to the establishment of the plastic waste circular economy by advancing pyrolysis technology and the achievement of the goal of establishing urban oil field company.

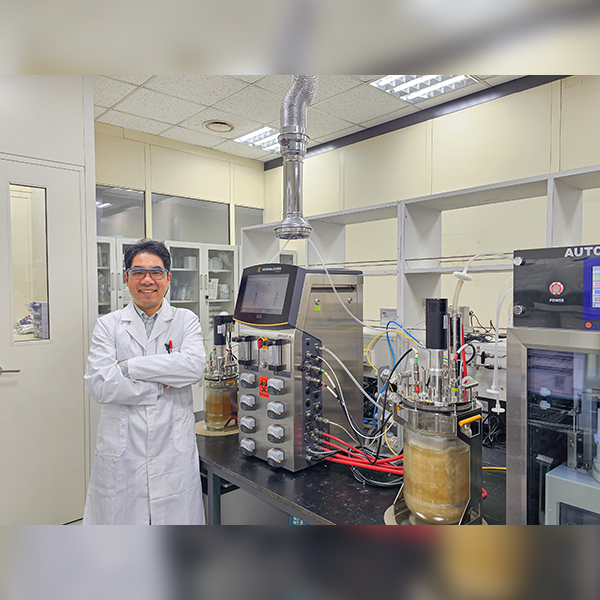

ㅣ SK Innovation’s Institute of Environmental Science & Technology’s various R&D activities to realize SK Geo Centric’s Green Transformation.

SK Innovation’s Institute of Environmental Science & Technology is the center of eco-friendly R&Ds for SK Geo Centric’s green transformation, which includes recycling technologies, 3R (Reduce, Replace, Recycle) solution, eco-friendly material development, etc. It offers eco-friendly energy and material-based solutions to support the conversion from Carbon to Green business, which is the gist of SK Geo Centric’s financial story, as well as all subsidiaries of SK Innovation.

To cite one primary endeavor made by the Institute of Environmental Science & Technology for establishing a plastic circular economy, there is chemical recycling technology development and application.

Concerning pyrolysis technology, one of the chemical recycling technologies, SK Geo Centric applied pyrolysis oil produced from the domestic SMEs specializing in plastic waste pyrolysis for the purpose of co-prosperity and win-win cooperation with SMEs, and employed the pyrolysis oil as the process fuel for its refinery and petrochemical processes for the first time in Korea and continues to engage in research for pyrolysis oil quality improvement.

In considering the gravity of the issue associated with plastic wastes, in addition, SK Geo Centric determined to secure a core pyrolysis technology on its own and consequently pursues a two-track strategy by seeking to construct a large-scale pyrolysis plant that combines SK’s own impurity removal technology through a global technology partnering.

So far, pyrolysis oil has not been considered as a feedstock oil due to concerns over air pollutant emission and facility corrosions caused by impurities such as chlorine. In cooperation with SK Geo Centric, the Institute of Environmental Science & Technology developed and applied post-treatment technology that eliminates impurities in pyrolysis oil, thereby turning it into eco-friendly feedstock oil.

In business partnership with a U.S. pyrolysis oil manufacturer, Brightmark LLC, SK Geo Centric is going to construct a large-scale pyrolysis plant, which embodies the combined global with SK Geo Centric’s own pyrolysis technologies and is scheduled to make a commercial operation in 2024. It marks the genuine birth of urban oil field where annual 200,000 tons of plastic wastes are recycled and produce about 1,080 thousand pyrolysis oil/year.

Besides, the Institute of Environmental Science & Technology seeks to introduce and develop depolymerization technology, one of the advanced chemical recycling technologies while focusing on high-value-added mechanical recycling technology and product development to minimize CO2 generation.

On the other hand, the Institute of Environmental Science & Technology also strives to establish a circular economy model where plastic wastes used for packaging materials are collected and separated for the production of recycled resins then molded into finished packaging products based on the tailor-made solution for customers for sales. The crux of technology lies in the ability to produce high-quality recycled resins based on solvent extracting technology thereby and to eventually convert plastic wastes to high purity plastic close to pure resin.

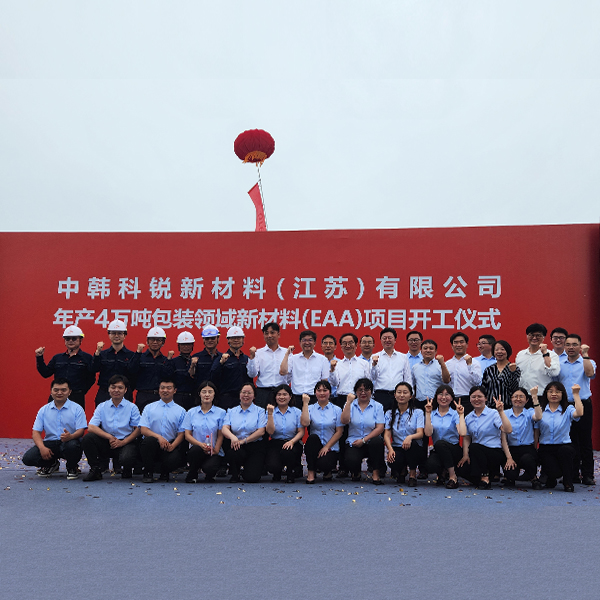

ㅣ Eco Creation, a Korean company that is taking lead in establishing the plastic circular economy and ESG management based on partnership with SK Geo Centric

In August, SK Geo Centric has acquired a 25% stake in Eco Creation, a South Korea-based pyrolysis company after joining an MOU together for plastic pyrolysis business in March. Newly introduced to the reporters this time, the New Eco One is a pyrolysis oil production plant that employs Eco Creation’s pyrolysis technology. The plant is running test operation at the moment, and expected to start commercial production in November this year.

Regarding pyrolysis oil technology, one of the next generation recycling technologies, SK Geo Centric employs and improves pyrolysis oil from SMEs with a view to ensure co-prosperity and win-win cooperation with SMEs and has been used as feedstock oils for its refinery and petrochemical processes from late last month for the first time in Korea. Pyrolysis oil to be produced by the New Eco One will be applied to SK’s oil refinery and petrochemical plants.

Eco Creation is the Ministry of Environment certified domestic pyrolysis technology holder and facility engineering company. The company obtained the New Excellent Technology(NET) certificate for its successful development of a pyrolysis plant based on key processes including its independent technology such as ‘catalyst control technology using catalyst towers.’

New Excellent Technology (NET) certification by the Korea Environmental Industry & Technology Institute under the Ministry of Environment is a system to promote the commercialization and market penetration of new technologies. As it mostly spans across other fields such as health, medical, and IT, it is highly rare for a manufacturing facility to get the certificate as in the case of Eco Creation.

With the commercialization of pyrolysis technology, Eco Creation is transforming plastic wastes into clean pyrolysis oil under the banner of the containment of environmental pollution encompassing GHG emission reduction and the blockage of the secondary pollutants such as dioxin by the incineration of plastic wastes, the mitigation of soil pollution by landfilling, and others.

Eco Creation’s pyrolysis technology applied to plastic wastes is about producing high-quality pyrolysis oil through thermal degradation of low-quality plastic wastes and comparing with the existing technologies, as it removes more than 80% hydrogen chloride generated from the thermal degradation process, it helps reducing air pollution.

Furthermore, it removes organic matters such as wax commonly found in ordinary pyrolysis oil to upgrade product quality, while it is possible to separate and produce naphtha, the main material for petrochemical production in a stable manner. As output yield is extraordinarily higher than other pyrolysis companies, it can be put in the field right away.

The cooperation between Eco Creation and SK Geo Centric has drawn much anticipation as the representative model for the win-win cooperation of eco-friendly ESG between SME and large companies as it can offer a fundamental solution to plastic waste issues based on the advancement of pyrolysis technology.

“We expect that the synergetic effect from both companies in the areas of environmentally-friendly and ESG management as the cooperation achieves the commercialization of plastic waste recycling technology and the production of high-purity pyrolysis oil,” said Kim Ji-yeon, Director of Eco Creation. “We will take the lead in contributing to the acceleration of carbon-neutral and establishing the waste plastic circular economy by working together to designate and register pyrolysis oil as an innovative product in the field of environment*,” Director Kim added.

* Only national projects or NET-certified products can be registered, and private contracts are possible in ‘”contracts with the state as a party’ as a system to support initial market entry and activate procurement linkage.

[Note] Explanation of key terms and technologies

|

※ Chemical recycling: A method of recycling waste plastics through a chemical reaction rather than a mechanical method through technologies such as pyrolysis and depolymerization. This method provides recycled plastic products that have quality as good as general plastic products, and better than the mechanically recycled (a method of crushing, washing, and melting waste plastics with a machine) one. This method is expected to grow fast in the future in that it provides a fundamental solution for plastic problem.

1) Pyrolysis: A technology that decomposes waste plastics such as waste vinyl with heat to extract raw materials, particularly naphtha, a raw material for petrochemical products. SK Geo Centric succeeded in developing a prototype of pyrolysis oil last year, and signed an MOU with Brightmark, a U.S. company, for cooperation in pyrolysis oil business in January this year.

2) Depolymerization: A technology that decomposes the polymerization of large molecular masses that make up plastics (PET, polyethylene terephthalate) such as colored PET bottles and polyester fabrics and returns them to the basic raw materials of plastics. In June this year, SK Geo Centric acquired a 10% stake in Loop Industries, a Canada-based company that owns methanol-based depolymerization technology.

|

[Photos]

Photo 1: Ham Hyeong-taek, CTO of Green Product Solutions Center, SK Innovation Institute of Environmental Science & Technology, explains about lightweight plastic materials for automobiles.

Photo 2: Ham Hyeong-taek, CTO of Green Product Solutions Center, SK Innovation Institute of Environmental Science & Technology, explains about eco-friendly single-material plastic containers.

Photo 3: Park Min-gyoo, Leader of Plastic CR (Chemical Recycle) Task, SK Innovation Institute of Environmental Science & Technology, describes the properties in each stage of waste plastic pyrolysis oil

Photo 4: Park Min-gyoo, Leader of Plastic CR (Chemical Recycle) Task, SK Innovation Institute of Environmental Science & Technology, explains about the post-treatment technology for waste plastic pyrolysis oil

Photo 5~8: An engineer at the New Eco One plant that applied Eco Creation’s pyrolysis technology tests the production facility.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin