SK Geo Centric

SK Geo Centric

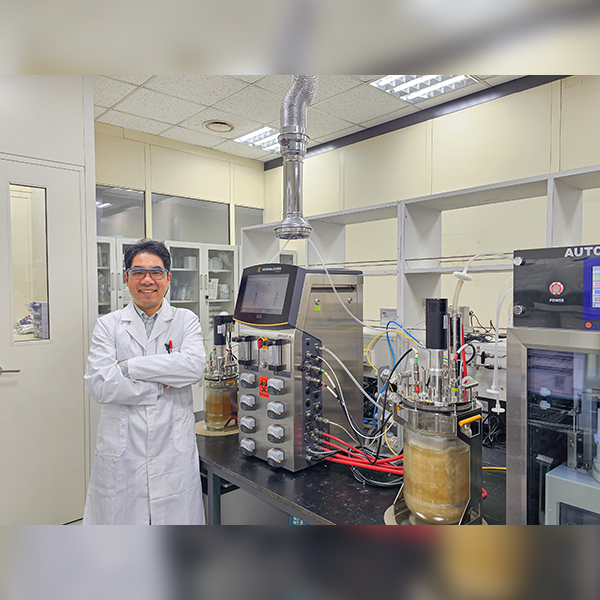

Setting its eyes on building a greener planet, SK Geo Centric (SKGC) completely revamped itself to achieve eco-friendly innovation and is proposing a blueprint for a plastic ecosystem reshaped by pyrolysis technology. Let’s find out how SKGC is taking Green Transformation through this technology through an interview with Lee Jong-hyuk, a leader of SKGC’s Green Business Group.

▲ Lee Jong-hyuk, a leader of SKGC’s Green Business Group.

| What is the direction of SKGC?

In a nutshell, to build the largest ‘urban oil field’ in the world. To be more specific, we would like to apply a differentiated technology to the treatment of plastic wastes with higher quality. At present, these wastes are currently either simply incinerated or being downcycled only to meet the increasing global demand for plastic wastes. With this technology, we would be able to supply high-quality recycled plastics to the market at premium rates. Through this, we can tackle both GHG and plastic waste issues at once, making great contribution to society and the environment.

Among various recycling methods, we are focusing on chemical recycling(1). SKGC is the only enterprise in the world that has secured a full package of three advanced technologies: pyrolysis(2), PET depolymerization(3), and PP solvent extraction(4). We plan to establish the world’s biggest cluster for chemical recycling of solid plastic waste by building three plants on a total area of approximately 214,876m2 in the industrial complex adjacent to SK Innovation Ulsan Complex.

(1) Chemical recycling: Indicating the methods of recycling plastic wastes not in a mechanical way but through chemical reactions. It is done by applying pyrolysis or depolymerization technology. Chemical recycling is superior to mechanical one, which involves mechanical processes such as grinding, washing, re-granulating, and compounding, in that it ensures better quality of the processed product. Products that are chemically recycled have quality equivalent to ordinary plastic product. As the technology offers a fundamental solution to the problem of plastic wastes, it is expected to bring explosive growth.

(2) Pyrolysis technology: A technology to break down plastic waste such as plastic bags with heat to extract raw materials, which can then be used to make petrochemical products.

(3) Depolymerization: A technology to convert the macromolecules consisting of plastics such as colored PET bottles and polyester textiles into smaller basic molecules.

(4) PP (Polypropylene) Solvent Extraction: A recycling method for polypropylene widely applied to various materials including polluted containers, plastic interior materials of an automobile, and others. It first turns a solvent into something in an intermediate state between liquid and gas by applying high pressure and temperature, then injecting it into a polypropylene tissue to extract unadulterated polypropylene in a way to remove pollutants.

▲ (Left photo) Indiscreetly discarded marine waste plastics / (Right photo) From left: Plastic wastes as a raw material for pyrolysis oil, pyrolysis oil, and post-processed pyrolysis oil.

| What is the current state of SKGC’s business regarding pyrolysis technology?

We are simultaneously pursuing the business in two different directions. One is to purchase pyrolysis oil in win-win cooperation with the domestic small-and-medium-sized recycling businesses. Then we will put it into the post-processing process that we are developing to remove foreign substances before using them as the material for a petrochemical process.

Another way is to form a partnership with overseas companies with advanced technology and build a medium or large-sized plant of our own. By achieving the economy of scale, we would then secure cost competitiveness. We are conducting an in-depth feasibility study on the establishment of a pyrolysis plant to treat 100,000 tons of plastic waste in Ulsan in conjunction with Brightmark of the U.S. that is running a pilot for the world’s largest pyrolysis plant with continuous processing technology. Besides, we are also seeking to build a 30,000- or 40,000-ton scale plant in Seoul Metropolitan Area in partnership with a pyrolysis technology provider who passed the verification process for a global commercial plant.

▲ (Left) SKGC and Ulsan Metropolitan City joins an MOU for “Investment in Eco-friendly Urban Oil Field Project for Plastic Waste Recycling” in July 2021

At present, though it is legally restricted to put pyrolysis oil into refined oil or as material for petrochemical plants, we tried to lift the ban through a regulatory sandbox. If the ban is revoked, it will make the first case for pyrolysis oil from plastic wastes to be introduced to oil refinery/petrochemical processes in Korea, and provide SK Innovation Affiliates with an opportunity to consolidate its leading position in the Korean circular economy through plastic waste recycling.

| Is pyrolysis business profitable enough?

Yes, I think it is more than enough. There are three good reasons for that.

First, it is forecasted that the recycling plastic market would be prone to be characterized by a tight demand-supply condition. In other words, demand would be short of supply in the market. We expect that companies in need of high-quality recycled plastics would look all for such providers.

Second, government regulations will expedite the increase in demand. Today, European countries are in pursuit of enacting a policy to make it obligatory for companies to contain 30% of recycled plastic in their products by 2030. And the Korean government requires companies to use 30% of recycled PET by 2030. At the moment, they are focusing on the public sector to require the mandatory use of recycled plastics.

Finally, we are certain that we can lower the costs by realizing the economy of scale by introducing advanced technology, which in turn, further improves profitability.

| What would be SKGC’s dream of the world in future?

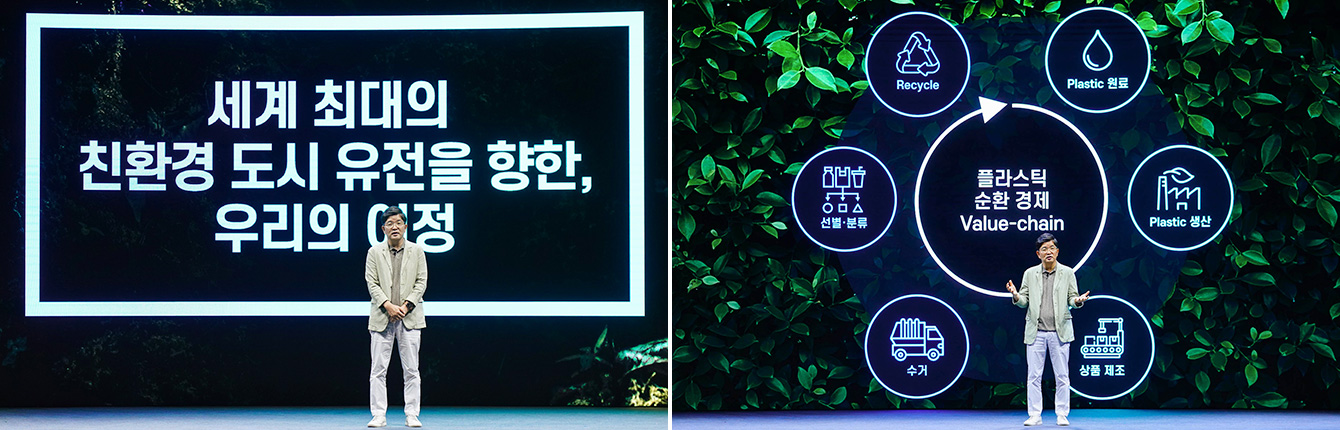

▲ CEO of SKGC Na Kyung-soo at the company’s “Brand New Day” event on August 31st, 2021

SKGC plans to expand its plastic waste recycling business with the production capacity for eco-friendly materials from the present 500,000 tons a year to 1.9 million tons in 2025 and 2.5 million tons by 2027. Capitalizing on the inverse concept of ‘urban oil field’ in which raw materials are extracted from plastic wastes, the company will lead the plastic waste recycling business beyond Korea and in Asia. Its ultimate goal is to leap forward to become a global company that drives a virtuous cycle of plastic waste resources.

We look forward to encountering a brilliant green transformation pictured by SKGC, which is transforming itself into a leading ESG company and aiming to be the world’s larggest ‘urban oil field’.

– SK Innovation’s endeavor to achieve Decarbonization by taking Green Transformation ① SK Innovation Ulsan Complex replaces Bunker-C boiler with eco-friendly LNG

– SK Innovation’s endeavor to achieve Decarbonization by taking Green Transformation ② SK Innovation & SK Energy take the initiative in accomplishing Net Zero with CCS technology

– Circular economy ② Plastic waste problem and example of SK Global Chemical’s responses

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin