SK Geo Centric

SK Geo CentricSK Global Chemical claims “to take the lead in creating environmental social value as a chemical company through strong innovation’ and “to solve chemical products problems such as plastic and vinyl waste with 3R”

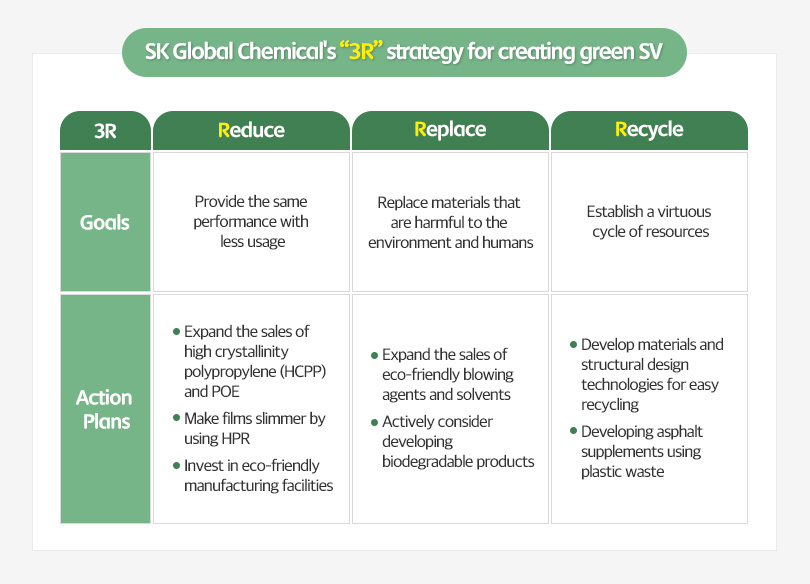

■ Taking the lead in creating green social values with the 3R strategy based on technology capabilities and the cooperation in the value chain

– Reduce (minimization): Develop materials that have the same performance with reduced plastic usage and expand the market

– Replace (substitution): Replace materials that harm the environment and humans; Expand the freon replacement market and low-toxic solvent market

– Recycle (recycling): Focus on developing single-material products that can be easily recycled as well as technologies to recycle plastic and vinyl waste through cooperation within the value chain

■ President & CEO Na Kyung-soo says, “We, a chemical company, will form a consortium with stakeholders to create an ecosystem for eco-friendly chemical products”

SK Global Chemical will take the lead in creating green social values (SV) through business-oriented “3R (Reduce/Replace/Recycle).” SK Global Chemical (CEO Na Kyung-soo, www.SKglobalchemical.com), Korea’s leading petrochemical company, has announced that it will actively implement its 3R strategy in an effort to proactively solve global environmental issues such as plastic and vinyl waste based on the company’s technology, R&D capabilities, and cooperation within the value chain.

This can be interpreted as the company’s willingness to actively implement SK Innovation’s green balance strategy (a strategy to increase social values in the environmental sector) with strong innovation. SK Global Chemical, which has emphasized SV management, created social values worth KRW 51.8 billion last year through the sale of eco-friendly products. And it plans to continue to increase the amount by specifying and sophisticating its goals with the 3R strategy.

To this end, SK Global Chemical formed an eco-friendly SV creation TF at the beginning of the year, met with 40 companies and organizations in the value chain to listen to the voices from the field on pain points and joint solutions, and specified 3R implementation strategies.

Based on this, the company held a workshop for green SV executives on June 4, and examined its strategies with the attendance of all the executives of SK Global Chemical, including CEO Na Kyung-soo. This came only a week after SK Innovation announced that it would practice green balance management with strong innovation.

Among 3Rs, “Reduce” means minimization and aims to reduce plastic usage by developing and selling materials which can provide equivalent performance but less usage in comparison with plastics. The representatives of such materials are high crystallinity polypropylene (HCPP(1)) and POE(2), and SK Global Chemical plans to develop new uses for these products and continue to increase their sales.

(1) High crystallinity polypropylene (HCPP): A high crystalline plastic used for automotive interior and exterior materials and various electric and electronic parts. SK Global Chemical’s HCPP products currently have the largest market share in Korea and China.

(2) Polyolefin elastomer (POE): A product with high crystalline rubber and plastic properties used for automobile interior and exterior materials as well as components and adhesives for various home and industrial products

High crystalline plastics, also known as eco-friendly plastics, are green products that can reduce the amount of use by about 10% compared to general-purpose polypropylene (PP). They can reduce the weight of a mid-size sedan by up to 10 kg, thereby improving fuel efficiency and reducing air pollutant emissions. In 2018, social value creation effects, such as reducing carbon dioxide emissions and car scrapping costs generated by sales of HCPP and POE for automobiles, are estimated at KRW 4.5 billion.

Furthermore, SK Global Chemical will reduce plastic consumption by sliming existing multi-layer packaging films with high-performance resins (HPR) while expanding investment in eco-friendly manufacturing facilities aimed at reducing energy consumption and pollutant emissions.

“Replace” means substitution, and the strategy is to replace existing products with eco-friendly products. SK Global Chemical primarily aims to expand the production and sale of eco-friendly blowing agents and solvents. In particular, sales of eco-friendly blowing agents, which can replace freon gas, a well-known greenhouse gas component, created KRW 44.2 billion worth of social value in 2018 alone.

Besides, the company plans to devise ways to replace materials that harm the environment and humans by actively considering the development of biodegradable products that can replace disposable vinyl and plastics, such as plastic bags, which have been banned at supermarkets since April 1, as well as eco-friendly low-toxic solvents.

“Recycle” literally means recycling. The aim is to create a virtuous cycle of resources by developing easy-to-recycle materials as well as technologies that can recycle plastic and vinyl waste.

SK Global Chemical will first take the lead in creating a recycling ecosystem for vinyl and plastic waste by developing materials and structural design technologies for easy recycling jointly with food and distribution companies as well as developing asphalt supplements using plastic waste that is difficult to recycle.

SK Global Chemical CEO Na Kyung-soo said, “Anti-environmental problems caused by chemical products such as plastic and vinyl waste is a supranational task that various stakeholders in the value chain must cooperate to cope with. SK Global Chemical will continue to develop 3R-related products and technologies based on its R&D capabilities as well as take the lead in creating an eco-friendly ecosystem across the chemical industry by forming a consortium with various companies and organizations in the value chain.”

[Photo Description]

1. SK Global Chemical CEO Na Kyung-soo explains the direction of the 3R strategy at the ‘SK Global Chemical Green SV Executive Workshop’ held on June 4.

2. Infographic of SK Global Chemical’s ‘3R’ strategy for creating green SV

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin