Press Releases

Press Releases■ Recruitment of development personnel for next-generation batteries such as solid state and lithium metal will begin on the 4th.

■ SK Innovation will keep making efforts to lead the lithium-ion battery market with its cutting-edge technology.

– Aiming to ensure safety in next-generation batteries based on the technology that has made zero cases of battery fire so far

■Lee Seong-jun, Head of SK innovation of SK Innovation Institute of Technology Innovation, emphasize, “We will continue to lead the global battery market by continuing the technical predominance of battery that has already been secured in the safest, fastest charging, and longest-lasting battery market while contributing to the development of the battery-related industry ecosystem.”

SK Innovation will start hiring next-generation battery development personnel from the 4th to the end of the year to accelerate its move to take the lead in the future battery market.

SK Innovation will hire personnel to develop solid electrolyte and lithium cathode technologies, which are in the limelight as the next-generation battery technologies. Through this, the company aims to use its unrivaled technology to dominate the lithium-ion battery market, which is the mainstream of the current market.

The recruitment areas include the developments of ▲ solid material; ▲ solid battery cells; ▲ lithium metal cathode. These will cover from developing materials for next-generation batteries to performance, life, and safety testing. Those with relevant work experience are preferred, while new researchers with master’s and doctoral degrees in related fields will also be recruited through a public announcement from November 9th to 22nd.

The next-generation battery is expected to be able to realize 1,000Wh/L or more, far beyond 800Wh/L – the limit of current lithium-ion batteries. The higher the energy density, the smaller the volume, and thus the less space it will take. Therefore, with the next-generation technology, it is possible to increase the mileage by installing more battery cells in the EVs. Besides, when a solid electrolyte is applied to complete a highly secured solid-state battery system with excellency in safety, safety-related components can be reduced, and various types of batteries can be manufactured. In short, the next-generation battery can dramatically increase the marketability for EVs, and this is why it is attracting much attention.

SK Innovation is evaluated as having the highest level of technology in producing batteries that are ternary compounds comprising nickel-cobalt-manganese (NCM), which is currently considered a trend in the EV battery market. The company has developed the world’s first batterries with a high nickel anode such as NCM622 (anode mixed with 60% nickel, 20% cobalt, 20% manganese), NCM811 (80%, 10%, and 10%, respectively), and NCM9½½ (90%, 5%, and 5% respectively).

In particular, while manufacturing such high-performance batteries, SK Innovation has secured high safety, recorded zero fire accidents among all EVs mounted with its batteries. Based on such technology, SK Innovation plans to lead the future market by securing safety, which is considered a challenging factor in developing next-generation batteries.

One of the most noticeable activities that manifests SK Innovation’s effort in developing next-generation battery is its joint work with the 2019 Nobel laureate John B. Goodenough. Since July, the company has been collaborating with Professor Goodenough and The University of Texas at Austin in hope of opening the next-generation battery area together.

“We will continue with the safest, fastest charging, and longest-lasting battery technology that we already have, take it to the next-generation battery and lead the global battery market. Meanwhile, we will keep contributing to the development of the battery-related industry ecosystem, including EVs,” said Lee Seong-jun, Head of SK Innovation Institute of Technology Innovation.

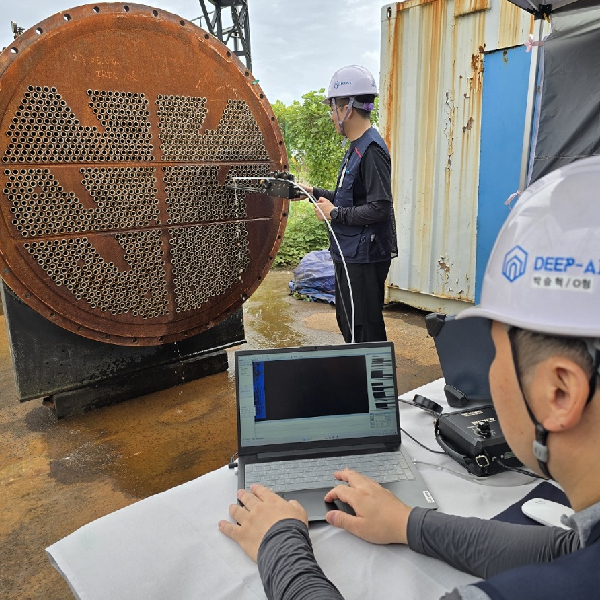

[Photo]

Researchers at SK Innovation Institute of Technology Innovation in Daejeon, Korea are developing next-generation battery technology.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin