SK Energy

SK Energy

The frequent rainfalls during the rainy season tend to ascend the risk of road pavement damage. When rainwater permeates into cracks on the asphalt pavement, it may give rise to potholes*, which are also called “land mines on the road.” It also increases the risk of accidents induced by aquaplaning**. To tackle this recurring problem, we have special products made by SK Energy, a leader in the Korean refinery industry. Let’s find out what it is and how it works through the contents below.

(*) Pothole: refers to a pot-shaped hole caused by partial deterioration or sinking of road surface

(**) Aquaplaning: is a condition in which a water film causes the moving tires of the vehicle to lose grip with the road surface on which it is rolling. If aquaplaning takes place, it is impossible to control the steering wheel, brakes, or accelerator.

ㅣ It is not “asphalt road” but “ascon road”

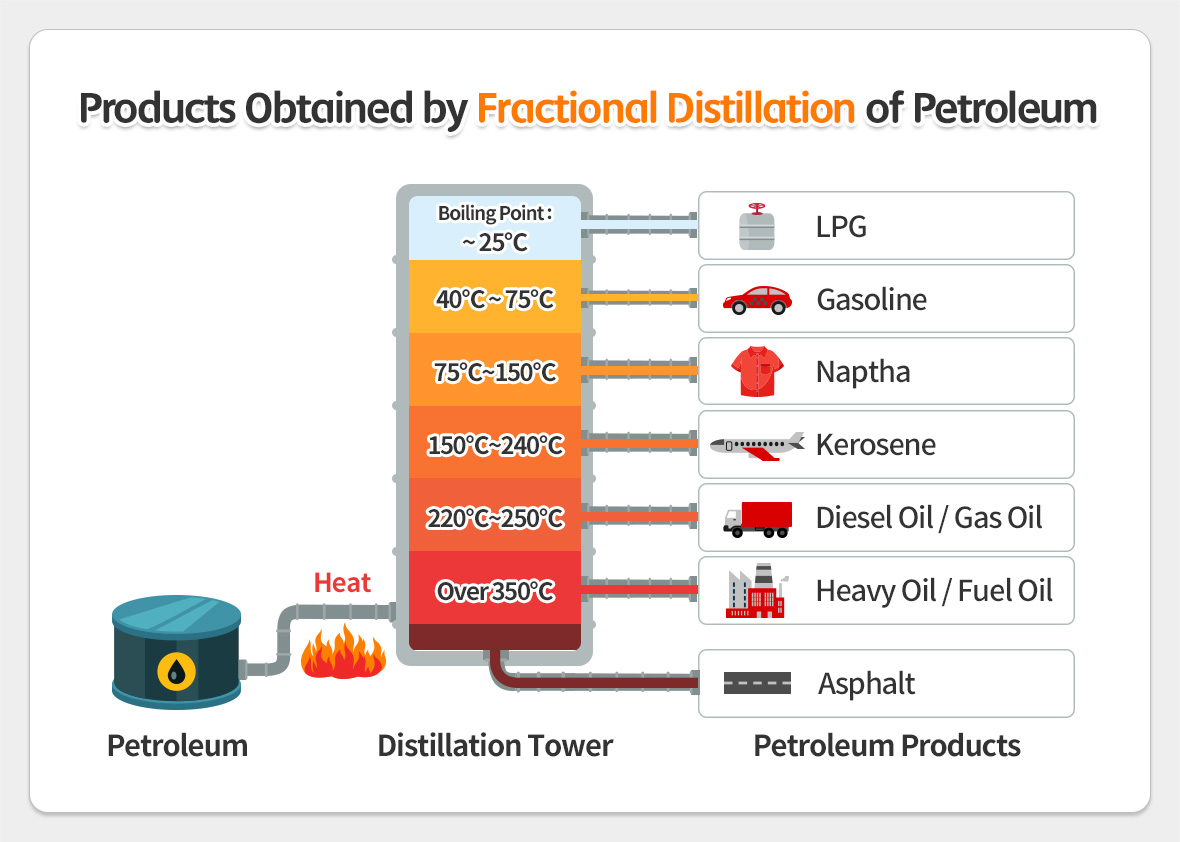

The road that we commonly call asphalt is actually named asphalt-concrete or “ascon” for short. Asphalt refers to the sticky residue obtained after refining crude oil to extract gasoline, diesel, and kerosene, and others.

Asphalt is one of the materials used in paving the road as it serves to bind the aggregates. Usually, asphalt pavement is made by hardening a mixture consisting of 5% of asphalt and 95% of aggregates at room temperature.

ㅣ SK Energy’s Premium Asphalt can solve multiple problems

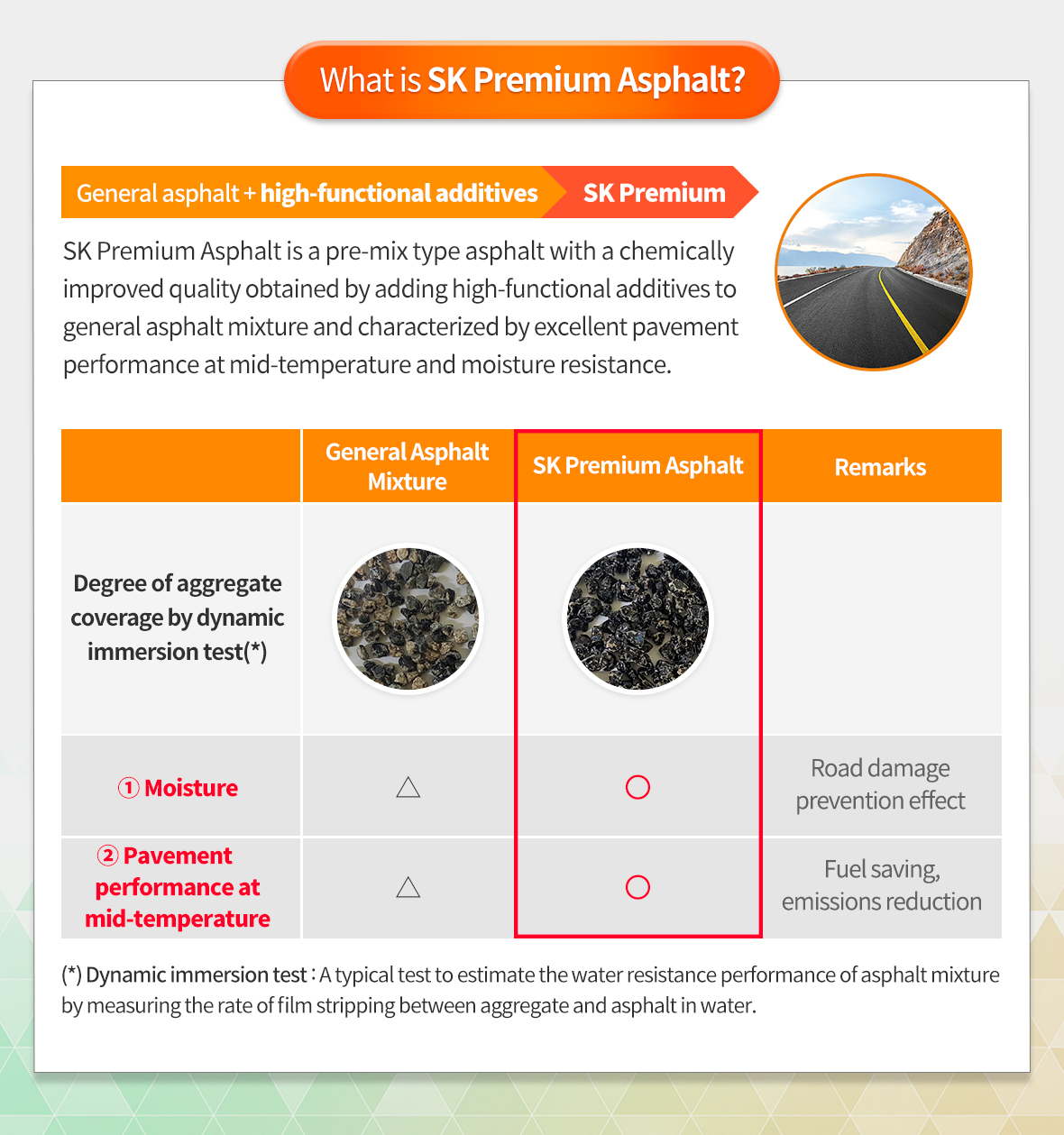

SK Energy, a subsidiary of SK Innovation, takes the lead in establishing an eco-friendly asphalt and road industry ecosystem by developing products that take account of various factors affecting the driving environment such as potholes, road damage, aquaplaning, noise, and more.

In particular, the Premium Asphalt products developed by SK Energy for the first time in Korea in 2018 is characterized by excellent functionality and paving performance at mid-temperature, making it possible to pave the asphalt mixture at about 30℃ lower heat than what is required by ordinary asphalt. It is also advantageous in alleviating road traffic congestion as it reduces not just the typical smell of the ascon and emission gas but also construction costs and the duration. With the upgraded moist resistance feature, the premium asphalt can also help lower the number of accidents associated with vehicle damage and casualties caused by road damage.

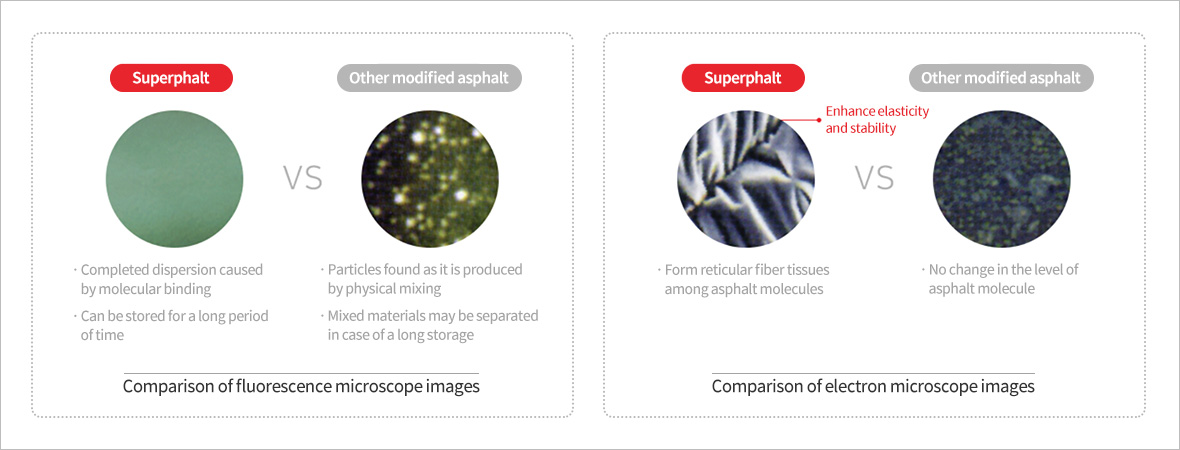

Moreover, SK Energy’s Superphalt and Polymer Modified Asphalt (PMA), which were first localized and developed for commercialization by the company in 1995, are products with high porosity and noise absorption features. As the Superphalt improves road pavement conditions, it serves to minimize vehicle and casualty accidents caused by road damage while decreasing the accident probability during rainfall with its reinforced porosity feature. In addition, as it cuts down noise levels significantly in the urban area, it is applied to locations plagued by noise-related civil complaints.

▲ Comparison between SK Energy’s Superphalt and other Polymer Modified Asphalt – Image Source: Official Website of SK Energy Asphalt

Besides, SK Energy also produces Recycled Asphalt, which is made of recycled ascon waste, thereby considerably reducing costs in treating waste ascon and creating environmental values. This line of product demonstrates the company’s commitment to practice ESG management, which is strongly enforced by all subsidiaries of SK Innovation.

Let’s recap SK Energy’s asphalt that takes care of road safety with “One-minute Innovation” video clip.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin