SK Geo Centric

SK Geo Centric

01ㅣ Used bale silage to up-cycled bags!

Have you ever seen multiple large cylindrical white objects that look like “giant marshmallows” lying in the fields and wondered what they are? Those huge, white bales that many of us have seen while passing a field are actually bale silages, stacks of straws wrapped in multiple layers of white plastic film to be fermented and used as feed.

▲ Bale silages that look like giant marshmallows

The plastic film used for baling is highly adhesive, which makes it easily contaminated. For this reason, it is rarely recycled and rather incinerated on the field, which sometimes may lead fire accidents. The amount of plastic film waste generated from baling is almost 1,200 tons only in Korea, and it is a major cause of environmental pollution.

To solve this problem, Dongmin Industrial Cooperative, a partner of SK Global Chemical, collects about 50% of the plastic film waste from the farms and SK Global Chemical uses them to create new products.

Dongmin Industrial Cooperative and SK Global Chemical mix the post-consumer recycled (PCR) Resin from the plastic film waste and virgin plastic to manufacture upcycled films and fabrics. Unpleasant odor inevitably occurs in this process; however, Dongmin Industrial Cooperative managed to use its technology to eliminate the odor and achieve a quality almost similar to virgin plastic. The upcycled films will be used for making the sacks to hold SK Global Chemical’s high-performance polyethylene, Nexlene™.

Existing sacks were originally made with 100% virgin m-LLDPE(1), but the upcycled sacks to be used in the future are composed of 65% m-LLDPE and 35% PCR resin and can reduce the carbon emission by 25%. Their physical properties are equivalent to virgin plastic that can be used in any logistics settings.

(1) m-LLDPE (Linear Low-Density Polyethylene): Uses a new metallocene catalyst instead of a Ziegler-Natta catalyst for better transparency and impulse strength

Moreover, the fabric made out of plastic film waste will be used to make the giveaways for the “Rest-cycle” campaign that SK Innovation, SK Global Chemical, and the Korea Expressway Corporation will launch together this summer at 199 expressway rest areas around the country. The eco-friendly social ventures including Montsenu, Right Route, and Usisan, which are supported by SK Innovation, are also developing products using this upcycled fabric and will launch them in August.

▲ Products made with the upcycled fabric: Montsenu (left), Right Route (center), Usisan (right)

02ㅣ Korea’s first recycling of aseptic cartons – the grand transformation of poly-aluminum!

In May, SK Global Chemical, Maeil Dairies, Tetra Pak Korea, and Jushin Trading signed an MOU to be the first case in Korea to recycle aseptic cartons by extracting plastics and aluminum composite materials (hereinafter composite material).

As aseptic cartons are made from paper and composite material, it has been difficult to separate each material for recycling. The paper materials from aseptic carton waste have been recycled and used as paper towels. However, the composite materials were all incinerated or landfilled.

The MOU will assign different responsibilities to each party. Maeil Dairies will develop and operate an aseptic carton collection program and consider introducing boxes made up of composite materials for food and beverage delivery. Tetra Pak Korea will provide recycling facilities for the selection and separation of aseptic cartons. Jushin Trading will recycle paper extracted from aseptic cartons and collect and supply the by-product, composite material, to SK Global Chemical. SK Global Chemical will use the supplied composite material to develop recycled plastic products for daily and industrial use such as pallets and delivery boxes for food and beverages.

▲ (Left) SK Global Chemical using pallet samples made from recycled aseptic cartons to transport products

(Right) Hangers made by SK Global Chemical using poly-aluminum (PolyAl) from aseptic cartons

This project is expected to recycle 3,000 tons of composite material and reduce 19,000 tons of CO₂ per year when it is completed. These figures are equivalent to planting 250,000 trees.

Currently, SK Global Chemical is producing visible achievements by upcycling aseptic cartons to produce pallets for logistics and hangers. In particular, the hangers made by PolyAl, a component of aseptic cartons that is difficult to recycle, will be supplied to domestic and global fashion brands and Walkerhill Hotels & Resorts in Seoul, Korea.

03ㅣ Plastic waste’s revival into eco-friendly crates

SK Global Chemical is working with a hiking and camping brand MinimialWorks to upcycle plastic waste into plastic crates.

MinimalWork uses recycled polypropylene (R-PP) developed by SK Global Chemical, which has the same properties as existing plastic, to make its upcycled product Folding Box Eco.

▲(Left) MinimalWork’s upcycled product Folding Box Eco made from SK Global Chemical’s R-PP / (Right) Folding Box Eco used as a container for firewood at a camping ground

Polypropylene (PP) is used to make disposable food containers and storage boxes. As more and more people started ordering food delivery services with COVID-19, the use of PP material has increased. PP has a lower recycling rate compared to other plastic materials, and even if recycled, the existing R-PP was hard to clean. Due to its smell and poor durability, it has been used only for low value-added purposes.

In a bid to solve this problem, SK Global Chemical used its original formulation technology to develop a new type of R-PP. By removing unpleasant odors and strictly managing the quality, the company was able to make properties equivalent to that of existing plastic. And it was first used to make camping equipment. SK Global Chemical’s R-PP boasts a great quality, which is by no means inferior to existing PP.

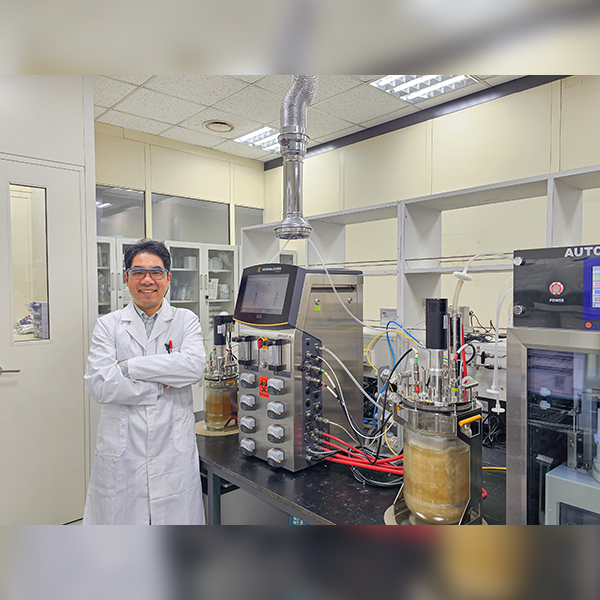

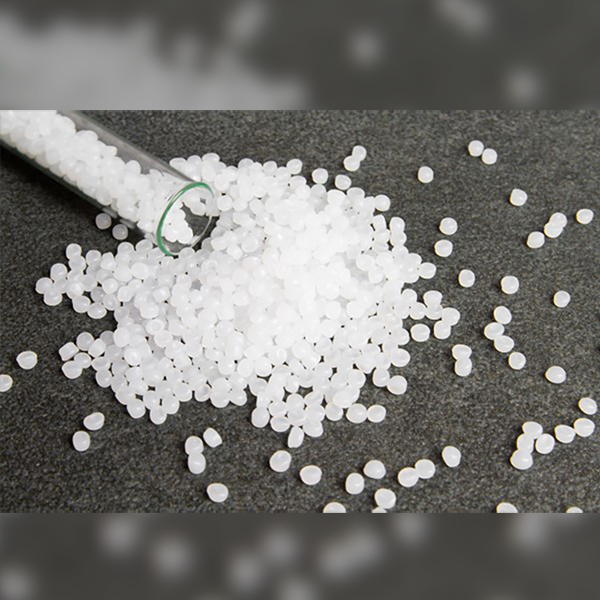

▲ (Left) A researcher at SK Global Chemical experimenting to improve the quality of R-PP / (Right) The sample of R-PP developed by SK Global Chemical

▲ (Left) A researcher at SK Global Chemical experimenting to improve the quality of R-PP / (Right) The sample of R-PP developed by SK Global Chemical

MinimalWork’s Folding Box Eco, made by using SK Global Chemical’s R-PP material, is the first camping equipment to use recycled plastic. Since a crate needs to be foldable and stackable, it has been difficult to use recycled plastic material with lower durability compared to regular plastic. However, with SK Global Chemical’s stronger R-PP material, manufacturing plastic crates with recycled plastic materials became possible.

In addition, recycled plastic materials such as SK Global Chemical’s R-PP can reduce CO₂ emission by 50 to 80% compared to general plastic materials. SK Global Chemical’s technology made it possible to recycle more plastics and to reduce the amount of plastic waste and CO₂.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin