SK Innovation

SK Innovation

Lee Seong-jun, CTO of SK Innovation and the Head of Institute of Environmental Science & Technology made a presentation on SK Innovation’s breakthrough technology and efforts for solving environmental problems at the International Conference on Carbon Dioxide Utilization (ICCDU) hosted on the 21st at the Korea Advanced Institute of Science and Technology (KAIST).

Founded in 1991, ICCDU is the largest international conference on the utilization of carbon dioxide where world-class scholars present and share their research on new uses of carbon dioxide.

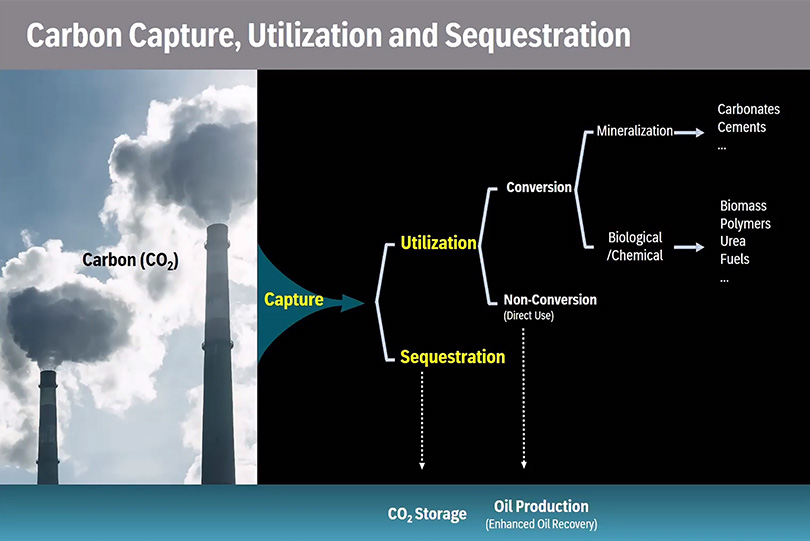

At the conference, Lee Seong-jun presented the areas of research and development that SK Innovation is currently focusing on. The presentation particularly emphasized ▲ the carbon capture utilization storage (CCUS) technology that captures and sequesters CO2 underground or on the seafloor, ▲ the pyrolysis and depolymerization technology for plastic waste recycling, and ▲ the battery metal recycling (BMR) technology to extract key minerals from waste batteries. These technologies play a key role in SK Innovation’s “from carbon to green” corporate structural transformation.

| CCUS

The CCUS technology, in particular, is considered an indispensable technology for CO2 emission reduction. SK Innovation is already utilizing its original technology to participate in various CCUS projects at home and abroad. And the industry expects SKI to solve the CO2 problem.

Since this May, SK Energy, a subsidiary of SK Innovation, has been promoting the national CCS project using the Korea National Oil Corporation’s West Sea Gas Field. The goal is to store 400,000 tons of CO2 in the West Sea Gas Field annually from June 2022, when the natural gas production is set to be shut down.

The company also participates in the EU-funded REALISE project, aiming to make a new-generation absorbent to capture CO2 in oil refineries, develop tools to verify and utilize CO2 capture technology, and secure the capability to evaluate the economic feasibility of CCS technology. This project will continue until April 2023 together with other industrial, academic, and research organizations from China and the EU.

| Plastic Recycling

Regarding the plastic waste issue, SK Global Chemical, another subsidiary of SK Innovation is developing relevant products and technologies based on 3R (Reduce/Replace/Recycle) strategy.

SK Global Chemical and SK Innovation Institute of Environmental Science & Technology have developed an original technology to replace its existing chemical materials with green materials. It has already released the eco-friendly PE wrap that can replace PVC, and PE-based one material that can replace PE/PET/NY multilayer packaging.

In addition, the company is developing a plastic-reducing technology to make packaging that uses less plastic and lighter automobile parts.

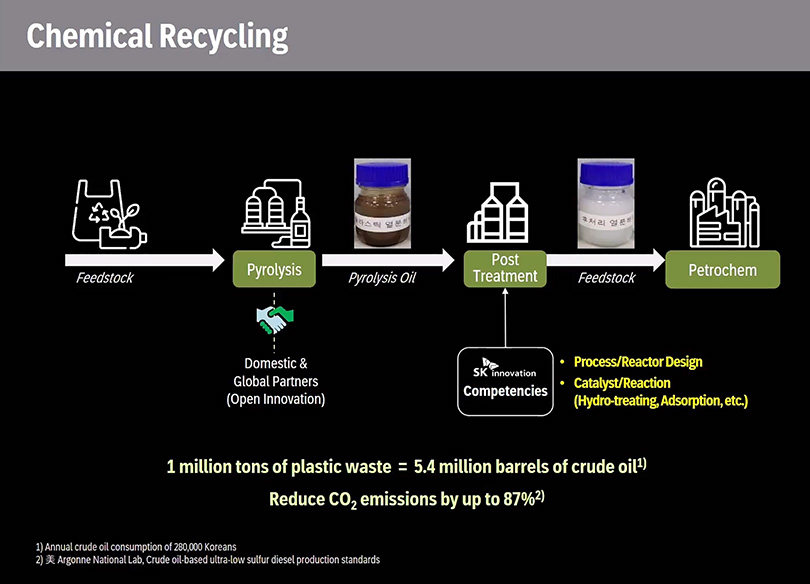

As for recycle, it is developing the pyrolysis technology, which uses heat to convert plastic waste into energy, and plans to improve the quality of pyrolysis oil, which is currently only used as fuel for industrial boilers, so that it can be used as feedstock at petrochemical plants. Moreover, it is actively working on depolymerization technology to recycle contaminated PET bottles and clothing that end up being incinerated or in landfills.

| Battery Metal Recycling

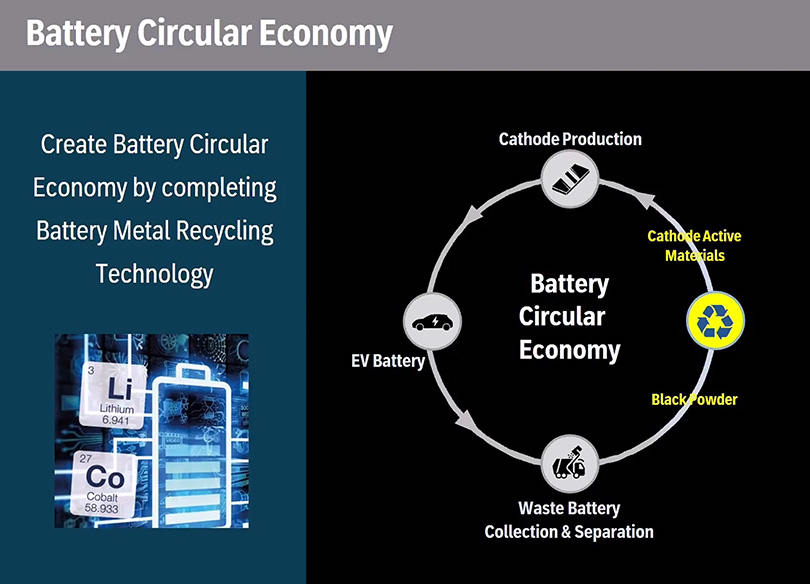

Lee Seong-jun also mentioned that SK Innovation has secured the technology to extract lithium hydroxide (LiOH) from waste batteries, explaining that extracting lithium first makes the extraction of other key minerals – nickel, cobalt, and manages – easier. Lee emphasized that this technology is more eco-friendly as it requires a smaller amount of chemicals used as solvents.

SK Innovation’s waste battery recycling technology has been verified for its eco-friendliness by Argonne National Lab, a national research institute under the US Department of Energy, as it can reduce CO2 emissions by 72% and 37%, respectively, compared to extraction of lithium from mines or salt lakes.

With this battery metal recycling technology, SK Innovation plans to establish a battery circular economy to solve social problems while also securing raw materials for batteries.

At the end of his presentation, Lee Seong-jun concluded, “SK innovation is transforming its biz portfolio from hydrocarbon to “Green Energy and Materials” based on ESG management for sustainable survival and growth. We plan to develop breakthrough technologies to accomplish this and cooperate with global industry and academia to solve environmental issues.”

– SK Innovation and SK Energy joined REALISE CCUS project for CO2 capture technology research cooperation

– CEO of SK Global Chemical proposes plan to recycle 100% plastic products at 2021 P4G Seoul Summit

– SK Innovation’s battery recycling technology recognized by U.S. Argonne National Laboratory

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin