SK Energy

SK Energy

After receiving much attention at InterBattery 2020, SK Innovation once again got a chance to show its technologies at 2020 Green New Deal Expo, which is taking place at Dongdaemun Design Plaza (DDP), Seoul, Korea from October 28th to 30th.

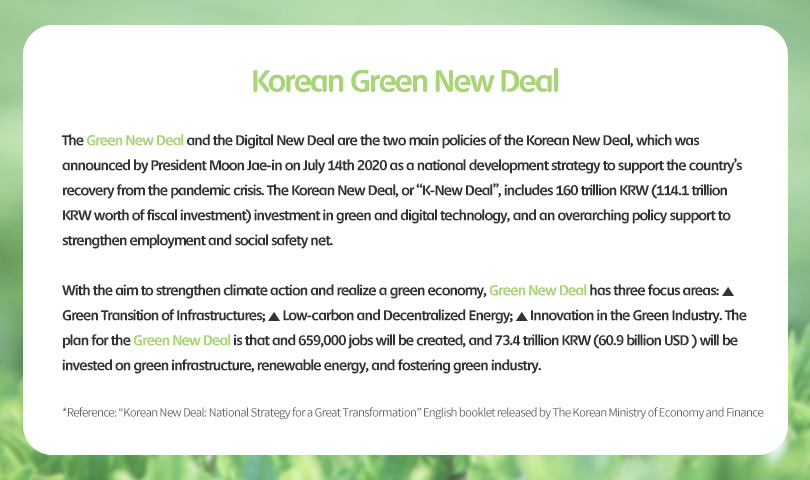

Hosted by the Korean National Assembly Hydrogen Economy Forum, 2020 Green New Deal Expo gathers various major corporates and organizations that are actively making efforts to reach the goal of transitioning to a low-carbon economy through developing green industry and energy conversion, as well as building a hydrogen ecosystem in line with the Korean Government’s Green New Deal policy.

South Korean Prime Minister Chung Sye-kyun, Minister of Trade, Industry and Energy Sung Yun-mo, Minister of Environment Cho Myung-rae and about 20 other key figures attended the opening ceremony of 2020 Green New Deal Expo, toured the exhibition hall and shared opinions regarding the future of clean energy in Korea. President of SK Innovation’s Battery Business Jee Dong-seob is the representative of SK Innovation at this event.

▲ (Left) President of SK Innovation’s Battery Business Jee Dong-seob at SK Innovation booth at 2020 Green New Deal Expo / (Right) Korean Prime Minister Chung Sye-kyun (first from right) and other key figures take a look at SK Innovation booth

SK Innovation booth at this event was designed under the theme of “Green Mobility” that aims to bring a safer and happier life to everyone.

▲ (Left) At the gate of 2020 Green New Deal Expo / (Right) SK Innovation booth at 2020 Green New Deal Expo

| SK Innovation’s Next Battery – “Safer than ever, faster than ever, and longer than ever”

SK Innovation booth has attracted a lot of visitors’ attention for its “Safer than ever, faster than ever, and longer than ever” Next Battery.

“Safer than ever”

The key factor that makes SK Innovation’s battery be recognized for its outstanding safety performance is the Z-folding process and in-house production of separators. Z-folding is a battery manufacturing method in which separation membranes are stacked in zigzag shape, and anode and cathode materials, instead of being folded, are inserted between those zigzag layers to enhance the durability.

Another strength of SK Innovation is that it is the only battery maker that can produce separators in-house. SK IE Technology, a material business subsidiary of SK Innovation, is a global top-tier separator manufacturer with world’s best technology. LiBS(1) products displayed at SK Innovation’s booth are mainly used for batteries of IT devices such as cellphones or laptops. On the surface of the LiBS is the CCS(2) that has a fine ceramic coating. CCS has the characteristics of greatly reinforcing heat resistance and strength to maintain the stability of the battery even at high temperatures and physical shocks, making it possible to create safer EV battery.

(1) LiBS (Lithium-ion Battery Separator, lithium-ion battery separator): A core material for batteries placed between the positive and negative electrodes of the battery in a thin film shape to prevent abnormal operation such as explosion and ignition, also a core high value-added products that affect battery performance and stability.

(2) CCS (Ceramic Coated Separator): A high value-added product reinforcing SK IE Technology’s mixed inorganic layer on one or both sides of a current lithium-ion separator, significantly increasing heat resistance and penetrating performance directly related to battery stability.

▲(Left) The LiBS and CCS displayed at SK Innovation booth / (Right) Visitors take a look around SK Innovation booth at 2020 Green New Deal Expo

“Faster than ever, longer than ever”

SK Innovation’s battery can be charged up to 80% with a quick charge in about 10 minutes, and the EV mounted with SK Innovation’s battery can achieve round trip between Seoul and Busan by charging only twice, each time takes only 10 minutes. It can reach long-range driving with a single charge and the battery can still maintain high efficiency even after thousands times of charges and discharges.

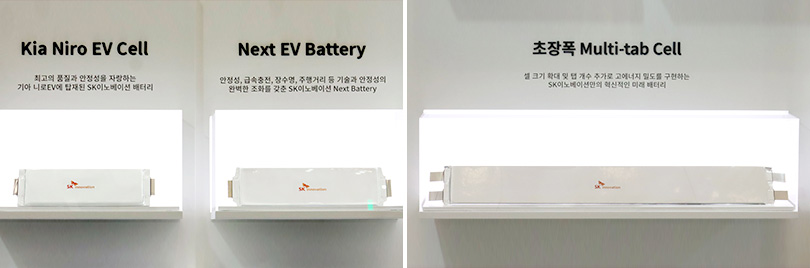

At SK Innovation booth, visitors can check the “Ultra-long multi-tab cell” that is being developed by the company as the next-generation battery. SK innovation is researching technology that increases the cathode material’s nickel content and applies high-capacity silicon to the anode material to realize high energy density.

▲ (Left) SK Innovation battery cell mounted on Kia Nero EV and SK Innovation’s Next EV Battery / (Right) SK Innovation’s “Ultra-long multi-tab cell”

Through the “SK Inside: Evolution for Future Mobility” video, SK Innovation introduces not only its battery technology but also the innovation of green mobility that it aims at. In particular, the video delivered a message to the audience about how our future will evolve with the innovative technologies pursued by SK Group, including battery, semiconductor, artificial intelligence, and lightweight materials.

▲ “SK inside: Evolution for Future Mobility” video played at SK Innovation booth

| SK Innovation’s battery world – Dream to be a “Total Energy Solution Provider”

The nearly 40 years of SK Innovation’s battery history is also shown at the expo. Through the “SK Innovation’s Battery World” exhibition model installed in SK Innovation booth, visitors can check how SK Innovation’s battery business expands beyond electric cars to E-Mobility, and the image of a future when all kinds of mobility have SK Innovation batteries inside.

In addition, visitors can take a look at the future complex charging station model that SK Energy, a subsidiary of SK Innovation majored in oil refining business, is planning to build. SK Energy is continuously expanding its charging infrastructure to keep pace with the increasing demand for hydrogen and EVs.

SK Innovation also introduced its BasS (Battery as a Service) platform business that manages battery lifetime from production to disposal to create a sustainable battery ecosystem. Through this, as a battery manufacturer, SK Innovation does not only produce but also continues research on the 5R (Rental, Recharge, Repair, Reuse, Recycle) that can complete the battery business’s total value chain. Furthermore, SK Innovation is making efforts in taking the lead in building a sustainable battery ecosystem by become the world’s first battery maker that succeeds in developing and commercializing the technology to extract high-purity nickel from waste batteries.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin