SK Geo Centric

SK Geo Centric■ SK Geo Centric obtains certifications on polymer production using recycled plastic raw materials and certification

■ Contributes to reducing plastic by making packaging materials and household goods with polymers made from renewable raw materials

■ SK Geo Centric will “increase the production of eco-friendly products that reduce plastic and its fields of application”

SK Geo Centric announced on January 30 that it has obtained the “Global Recycled Standard (GRS)” from Control Union, an international certification body.

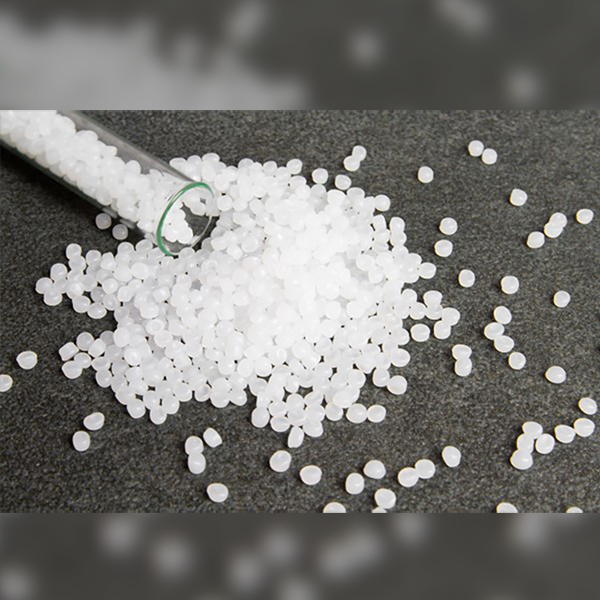

SK Geo Centric received its GRS certification for polymers made with renewable raw materials. Usually, polymers are made using Naptha, but SK Geo Centric also produces polymers that recycle waste plastic. Polymers are used to make various plastic products, such as vinyl, packaging containers, home appliances, and automotive products.

The GRS certification issued by Control Union, which has its bases in the Netherlands, is an international regeneration standard certification given to products that include 20% or more recycled materials with a traceable usage history. GRS is a credible certification that checks the content of renewable raw materials as well as the compliance with social, environmental, and chemical standards. Certain global consumer goods companies require GRS certification as its standards for transaction. As SK Geo Centric’s polymer has met global standards, increased exports are expected in the future.

With the heightened interest in recycled packaging materials in Korea, SK Geo Centric has been continuously collaborating with domestic companies. SPC Pack, a packaging material manufacturing company of the SPC Group, plans to make packaging materials for household goods using SK Geo Centric’s polymers that were GRS certified. This is the first time that all companies in the process, ranging from manufacturing renewable raw materials (SK Geo Centric) to the processing production (SPC Pack) have obtained the GRS certification.

The packaging material will be used for the “Daily Kitchen Towel” product by KleanNara, a comprehensive paper manufacturer. The company aims to increase the portion of renewable raw materials for packaging materials from 20% to up to 50% within this year. When a product uses renewable raw materials for 50% or more, the final product can display the GRS certification mark. The three companies plan to collaborate in increasing the number of products using eco-friendly packaging materials to seven products in the near future.

SK Geo Centric’s Head of Solution Business Division Choi Woo-hyuk said, “We are pleased to be recognized for the excellence of our products by receiving GRS certification for polymer products using renewable plastic raw materials.” He added, “We plan to increase production and exports, ranging from household goods to home appliances and automobile materials, to strengthen our capabilities on developing eco-friendly packaging materials and expand its scopes of application.”

[Photo]

SK Geo Centric members introduce the Daily Kitchen Towel product that uses renewable packaging materials certified by GRS

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin