SK On

SK On■ The two signed an MoU to cooperate in establishing a digital twin for battery manufacturing factories

■ SK On aims to solidify its smart factory strategy, improving operation cost efficiency while further innovating manufacturing

SK On is collaborating with the global tech company, Siemens Digital Industries Software (Siemens DISW), to establish a smart factory system. The partnership is expected to enhance its manufacturing competitiveness by innovating the battery cell manufacturing process and reducing costs.

SK On announced that it has signed a memorandum of understanding (MOU) on cooperation in developing digital twin for battery manufacturing factories with Siemens DISW on the 12th at the SK Seorin Building in Jongno, Seoul, South Korea.

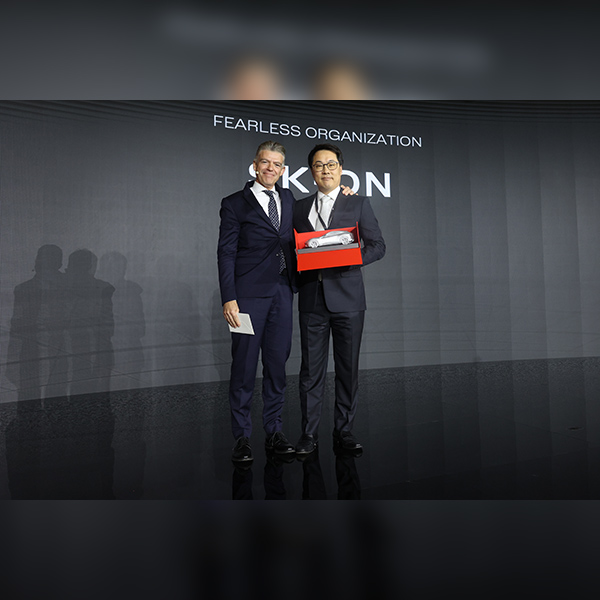

Lee Seok-hee, CEO of SK On, Oh Ki-young, Head of SK On Factory Innovation Office, Tony Hemmelgarn, CEO of Siemens DISW, and Oh Byung-joon, Siemens DISW Korea Managing Director, attended the signing ceremony.

A “digital twin” is a technology that replicates a factory in a virtual environment for simulation before and after its design and operation. Siemens is renowned for its unparalleled expertise in this field.

SK On plans to utilize the digital twin software and simulation technology included in Siemens DISW’s Xcelerator* product line. The company expects significant reductions in equipment maintenance time** or operation costs through real-time monitoring between the virtual factory and the actual site.

* Xcelerator: an open digital business platform by Siemens

** Equipment maintenance time: the time during which operations are halted for routine inspections or repairs of equipment

Applying digital twin technology to new factories will enable rapid verification of optimized manufacturing lines, thereby shortening the time required to build factories.

SK On plans to establish a digital twin factory in Korea first and then expand this model to other global factories in the United States and Europe to solidify its smart factory strategy.

SK On is currently actively pursuing its smart factory strategy. Last year, the company signed multiple MOUs with Korean and international partners for battery production equipment intellectualization. Controllers that oversee equipment control, smart sensors for monitoring, communication networks, and power devices are among the targeted equipment.

“SK On will expand cooperation with leading global partners, including Siemens, to strengthen our manufacturing competitiveness,” said Lee Seok-hee, CEO of SK On.

Tony Hemmelgarn, CEO of Siemens DISW added, “I am very pleased that we can cooperate with SK On by providing the Siemens Xcelerator portfolio to help bringing digital production innovations and creating a sustainable battery industry.”

[Photo] Lee Seok-hee, CEO of SK On, (left) and Tony Hemmelgarn, CEO of Siemens DISW, are taking a photo after signing a memorandum of understanding (MOU) on cooperation in developing digital twin for battery manufacturing factories at the SK Seorin office building in Jongno, Seoul on April 12th.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin