SK Incheon Petrochem

SK Incheon Petrochem

The very site of green transformation where you can actually eye-witness SK Innovation affiliates’ commitment to decarbonization! As the fourth episode of this series, we present SK Incheon Petrochem’s process heat source recovery project, which involves energy upcycling in which waste heat from processes is recollected to produce cooling and heating energy for local residents.

As fully engaged in its effort to identify eco-friendly business models, SK Incheon Petrochem has established a shared infrastructure for the local community where waste heat generated in the course of producing petrochemical products is recollected and used as an energy source for heating and cooling. Let’s hear about green transformation from Lee Hyo-jin, Head of SHE Tech Office, SK Incheon Petrochem.

▲ Lee Hyo-jin, Head of SHE Tech Office, SK Incheon Petrochemical

| To begin with, could you explain more about this Process Heat Source Recovery Project?

To produce petrochemical products, it is necessary to heat up crude oil at high temperatures to separate it into different types of oils such as diesel, kerosene, and gasoline. It is customary to discard any redundant heat that is not recovered in the process. SK Incheon Petrochem recovers a low-level heat source to supply local residents as a heat source for cooling and heating. In other words, it might be best to put it in this way, what we are doing is ‘energy upcycling.’

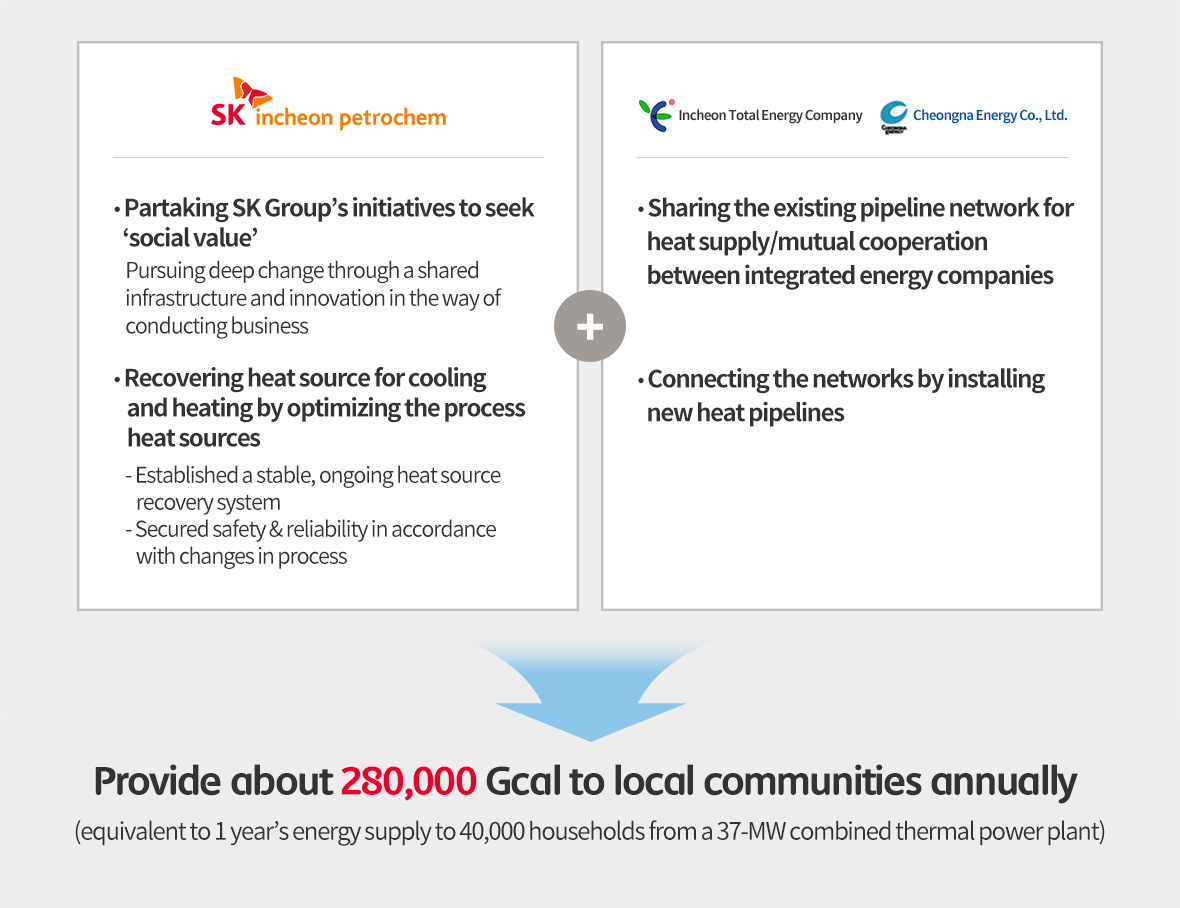

To do so, SK Incheon Petrochem has signed an MOU with local integrated energy companies in 2018 and has been conducting a ‘district cooling and heating energy supply project utilizing heat source of petrochemical process’ as the first company in the domestic industry since 2019.

| In which process do the heat source’s recovery and supply take place?

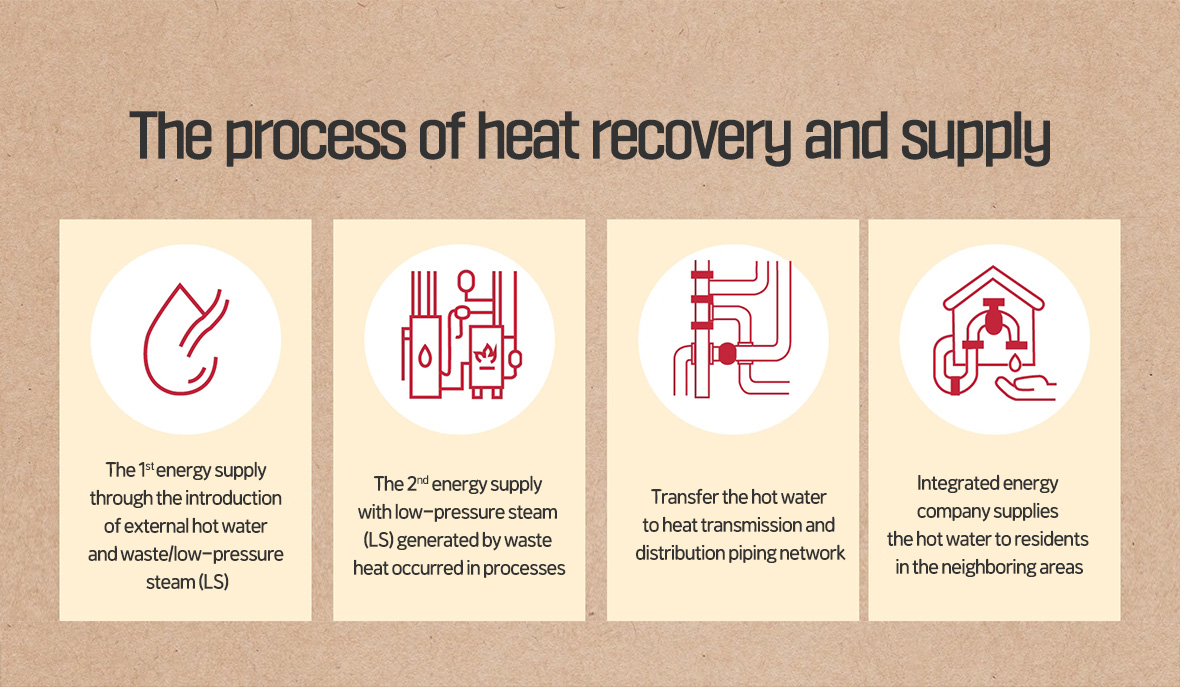

First, we apply heat that is not retrieved after the production process of petrochemical products, or waste heat, to raise the temperature of the external hot water step by step. As the heated water is then delivered through the heat supply pipeline network of an integrated energy company, it obviates the need for additional input of fossil fuels and can be directly used as a cooling and heating energy source for local residents.

| What is the background for implementing the Process Heat Source Recovery Project and its significance?

This project can be best understood as an example of turning what has been conceived as a risk, ‘urban expansion around company’, into a business opportunity. To be exact, discarded energy is recovered to establish a sharing infrastructure for the local community. It can be viewed as a business model that tackles both sustainable social value and economic value at the same time. Furthermore, we have not just obtained the supply source of heat sources necessary for the company in the future, but also established a platform to cultivate a group energy supply business.

| What are the effects of the Process Heat Source Recovery Project?

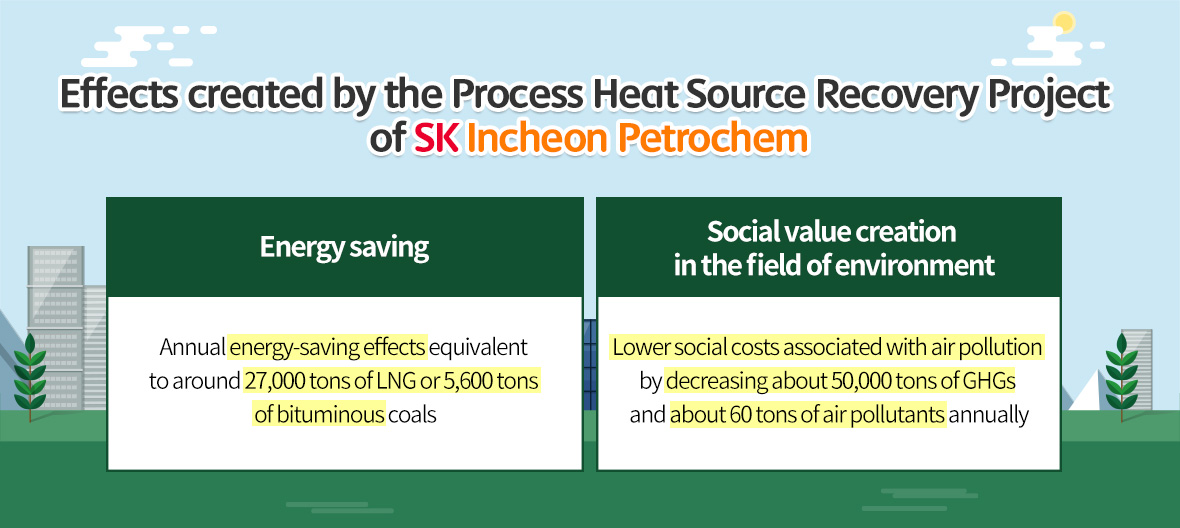

Heat sources provided by SK Incheon Petrochem are currently put to use as cooling and heating energy in large-scale residential complexes in Incheon. The total energy reaches about 280,000 Gcal* per year, which is tantamount to the output of a 37-MW combined thermal power plant. It stands on par with the amount of energy generated by 27,000 tons of LNG or 5,600 tons of bituminous coals. Or to put it differently, it is a year’s supply to 40,000 average households.

(*)Gcal (Giga calorie): A unit of calorie applied to mechanical systems and others. As Giga represents 109, Giga calorie equals 1 billion calories.

Another notable point we should not miss is that as the Process Heat Source Recovery Project serves to reduce about 50,000 tons of GHGs and about 60 tons of air pollutants a year, it has also significant in terms of environmental value.

| Tell us about plans for the Phase-2 Project.

To maximize the effect of the project, SK Incheon Petrochem plans to diversify its endeavors: for instance, it will link the Phase-1 Heat Source Recovery Project with the expansion within the existing processes in order to collect available additional heat sources. Accordingly, the company plans to ensure the Phase-2 Project that explores extra retrievable waste heat in order not just to supply outside but also to use internally. The project is in progress and scheduled to run a pilot operation by late 2022.

When the Phase-2 Project is completed, combined with the Phase 1, it is expected to reduce 75,000 tons of GHGs and 90 tons of air pollutants every year. SK Incheon Petrochem will not be content to stop here but keep on identifying eco-friendly business models to take a lead in practicing ESG management.

The green transformation shaped by SK Incheon Petrochem, a company fully committed to ESG management and creating not just economic but also socio-environmental values with a brilliant paradigm shift.

– SK Innovation’s endeavor to achieve Decarbonization by taking Green Transformation ① SK Innovation Ulsan Complex replaces Bunker-C boiler with eco-friendly LNG

– SK Innovation’s endeavor to achieve Decarbonization by taking Green Transformation ② SK Innovation & SK Energy take the initiative in accomplishing Net Zero with CCS technology

– SK Innovation’s endeavor to achieve Decarbonization by taking Green Transformation ③ SK Geo Centric tackles plastic waste issues with pyrolysis technology

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin