SK Geo Centric

SK Geo Centric

SK Global Chemical, a chemical business subsidiary of SK Innovation, and Cleanwrap Co., Ltd, a Korean food packaging company, announced that they have successfully developed eco-friendly wraps for commercial use.

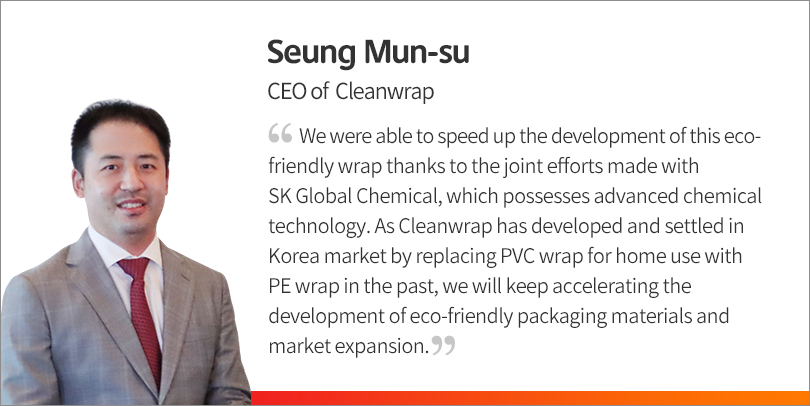

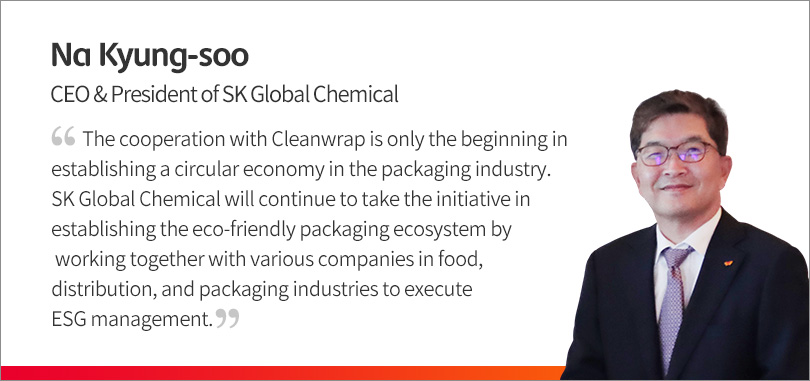

On November 26th, SK Global Chemical and Cleanwrap introduced their jointly developed “Eco-friendly PE (Polyethylene) wrap for commercial use” at the Headquarter of SK office in Seoul, Korea. The event was attended by CEO & President of SK Global Chemical Na Kyung-soo and CEO of Cleanwrap Seung Mun-su. The two companies decided to keep collaborating in the future to strengthen ESG management by further expanding joint development of eco-friendly packaging products.

Cleanwrap is the first Korean company in the food packaging industry that released the harmless to human product – LLDPE (Linear Low Density Polyethylene) Wrap. This product has received patents in five countries and was approved by the US FDA (Food and Drug Administration). Cleanwrap is not only the number 1 food packaging company in Korea but also a familiar name in various foreign markets.

SK Global Chemical, which is taking the lead in establishing a circular economy by solving environmental problems such as waste plastic issues, was the first one to propose this joint development of the “Eco-friendly PE wrap for commercial use” to Cleanwrap, its long-time customer.

▲ CEO & President of SK Global Chemical Na Kyung-soo (first from left) discusses with the other attendees before the event

The increasing demand for eco-friendly packaging materials in Korea is among the major reasons behind this collaboration. In the past, Polyvinyl Chloride (PVC) was the more widely used material in commercial use packaging. PVC has various strong points, such as its resistance to moisture and easy-to-stretch feature. However, when PVC is mixed with other synthetic resins, its intensity decreases and toxic chemical substances are generated, which makes it impossible to recycle. Therefore, wrap products made of PVC are classified as general waste.

In Korea, from last December the Ministry of Environment prohibited the use of PVC wrap, which is difficult to be recycled, with the exception for only some products, such as hams and sausages, which have no substitute material.

It is essential for the packaging industry to develop substitute materials that can be recycled and do not emit harmful substances during the recycling process, while maintaining the strong points of existing PVC wrap products.

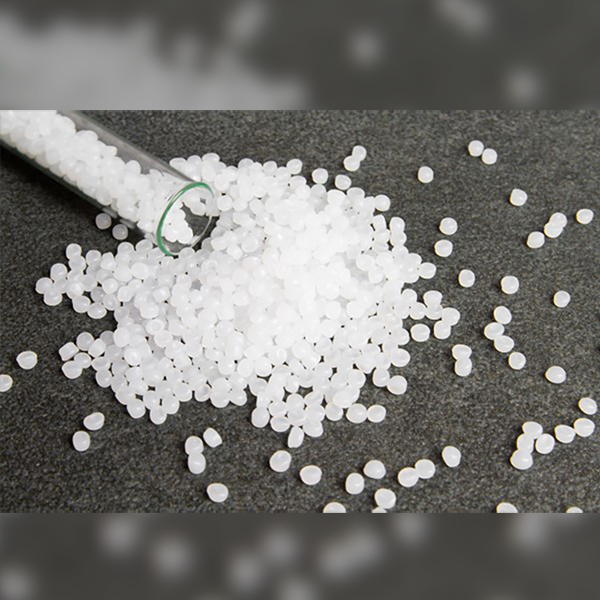

The material of the commercial use eco-friendly wrap jointly developed by SK Global Chemical and Cleanwrap this time is Polyethylene (PE). It was made to replace the PVC wrap mainly used for food packaging, such as meat sold at major supermarkets and delivery food.

▲ (Left photo) CEO & President of SK Global Chemical Na Kyung-soo (right) and CEO of Cleanwrap Seung Mun-su (left) at the event to introduce jointly developed eco-friendly wrap product / ▲ (Right photo) The “Eco-friendly PE wrap for commercial use” product

The eco-friendly PE wrap for commercial use was successfully developed based on SK Global Chemical’s high-functional PE material in-house technology and ultra-thin layer design technology, and Cleanwrap’s accumulated knowledge for home use PE material development. It is harmless to the human body and recyclable. The product also has excellent elasticity for easy packaging. Furthermore, it does not generate harmful substances when incinerated, and can be recycled without separating from the synthetic resins.

Currently, the development of a prototype of “Eco-friendly PE wrap for commercial use” has completed. The finished product is planned to be released and commercialized within the first half of next year.

The successful development of this eco-friendly product attracts great attention from the packaging industry, which is in urgent need for materials that can substitute commercial use PVC wrap. Industry insiders are anticipating a more rapidly change to eco-friendly PE wrap from the existing PVC one in the market.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin