Trends & Reports

Trends & Reports

The world is locked in ice. Skyscrapers in New York City and the Statue of Liberty are buried waist-deep in snow, as if the Ice Age has returned. With the power out, people struggle to survive. This eerie scene from the 2004 disaster film The Day After Tomorrow felt almost prophetic when the devastating blizzards of 2022 hit the U.S. and Canada, bringing the movie’s chilling vision to mind for many.

Imaginary drawing of an electric vehicle on a snowy New York street (AI-generated image)

| The rise of electric vehicles and secondary batteries

Twenty years ago, there was something absent from the 2004 movie: electric vehicles (EVs), as there were not many on the roads at that time. However, things have changed. At the end of 2022, amid the chaos of a historic winter storm in North America that caused massive power outages affecting nearly 1 million homes and offices across Canada, a post on the major U.S. online community Reddit caught people’s attention. A Canadian shared how his Ford F-150 Lightning, equipped with SK On’s NCM9* battery—developed in 2020 as the world’s first—powered his fridge, Wi-Fi, lights, and TV for 44 hours during the blackout, and still had 65% of its battery left. His EV turned out to be a true lifesaver.

*NCM9: a high-performance, high-nickel battery containing approximately 90% of nickel, along with cobalt and manganese

In the past, we could only access electricity within the limits of power lines. Now, with the leap in secondary battery technology, we can use electricity freely, anytime and anywhere. As seen during the North American blizzard, these batteries kept life running smoothly despite power outages. They’re also becoming essential backup power sources for critical facilities like hospitals and data centers. As technology advances, the usage of secondary batteries is set to expand even further.

| Secondary batteries – beyond smartphones and EVs, also inside our bodies?

Clockwise from the top left: EVs, wireless earphones, and logistics industry robots powered by secondary batteries

🔍 [Electric Vehicles] Breaking the stereotype of just being a “mode of transport”

Secondary batteries are the “heart” of electric vehicles, providing the power stored in large-capacity cells to run the motors. Unlike conventional cars that rely on burning fossil fuels such as gasoline, diesel, or LPG to drive their engines, electric vehicles depend on these batteries. According to the International Energy Agency’s Global EV Outlook 2024, electric vehicles sold in 2023 will emit roughly half the carbon dioxide of traditional internal combustion engine vehicles over their lifetime. This makes electric vehicles a cutting-edge solution for tackling climate change and accelerating the transition to clean energy.

Based on their energy sources and operation, electric vehicles are typically classified into three main types: BEV (Battery Electric Vehicle), HEV (Hybrid Electric Vehicle), and PHEV (Plug-in Hybrid Electric Vehicle). BEVs operate their motors solely by electricity stored in their batteries and do not use internal combustion engines. This means they’re equipped with high-capacity batteries that provide impressive energy density and output. HEVs combine internal combustion engines with electric motors and typically use nickel-metal hydride (NiMH) or lithium-ion (Li-ion) batteries, which are known for their durability and performance. PHEVs have larger battery capacities than HEVs and can be charged using external plugs.

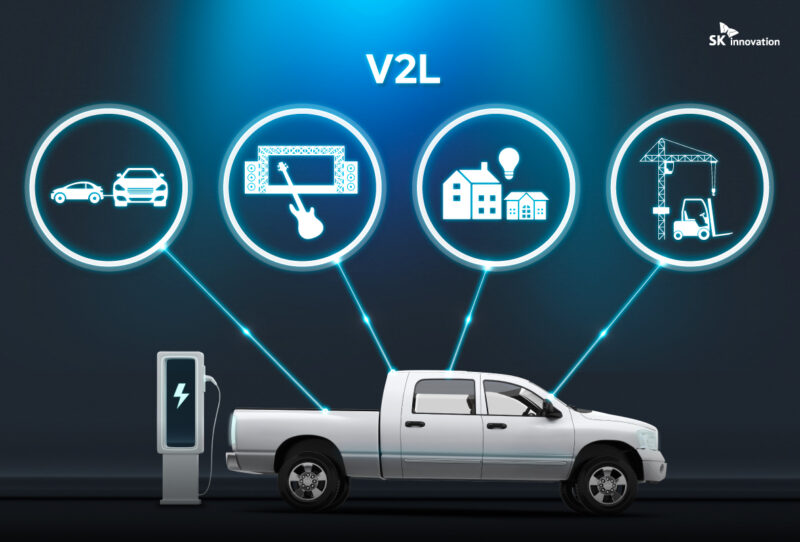

Electric vehicles are making headlines for their ability to act as portable power sources, thanks to their V2L** function, which allows them to supply power externally, ideal for camping and other situations where reliable electricity is less accessible.

**V2L (Vehicle-to-Load): the ability of an EV to supply power to external devices and appliances using its battery

Recently, Canadian freelance journalist, Benjamin Hunting, shared his story on the Candian automotive news site Driving.ca, which quickly gained attention. He hosted his wedding in a forest outside the city, where the biggest challenge was the lack of electricity. The catering service needed ample power for cooking and lighting, and the guests needed to navigate the dark, wooded area safely. The solution? The Ford F-150 Lightning electric pickup truck. Its SK On’s NCM9 battery provided more than enough power to keep the event running smoothly, despite the limited electricity and plug availability at the venue, much to the journalist’s amazement.

Benjamin Hunting praised the truck, calling it “a battery with a truck attached.” He added, “Even more impressive? After putting in a full 13 hours of work, the F-150’s battery was still at 94% capacity. ” He also noted, “We could have immediately slipped behind the wheel and driven off on our honeymoon without having to hit up a charger on our way out of town.”

🔍 [ESS] Tackling power uncertainty with “this” solution

Energy Storage Systems (ESS) not only alleviate peak load during high-demand periods by supplying stored power, but also act as critical backup during power outages, providing emergency support to essential facilities like communication centers and data hubs. Additionally, ESS optimizes energy consumption by efficiently storing and releasing excess energy from variable renewable sources such as solar and wind.

SK On is currently developing commercial ESS batteries, prioritizing safety and offering comprehensive battery solutions, including optimized management systems for cells, modules, and racks. At InterBattery 2024, Korea’s largest battery exhibition held in March, SK On unveiled high-nickel and LFP (lithium iron phosphate) ESS modules, along with a next-generation DC block model that connects modules in series and parallel, capturing the attention of attendees. At the event, SK On also showcased its thermal propagation prevention solutions, certified for fire safety in North America, and a liquid cooling system designed to minimize cell temperature differences and enhance charging and discharging efficiency.

🔍 [Wearable Device] Small and lightweight batteries

Secondary batteries are at the core of advancing everyday electronic devices like wireless earphones, smartwatches, and smart glasses. The latest smart devices are compact yet feature high-performance and other functions such as noise cancelling and AI, which drive up power demands and, in turn, increase the need for batteries with higher energy density. Consequently, the demand for higher energy density in the batteries used in these devices keeps growing. Recent innovations have led to the development of flexible batteries that can bend or even attach like stickers, thereby improving the comfort and usability of wearable devices.

🔍 [Medical Device] Batteries operating inside the human body

The development of miniature secondary batteries is expected to revolutionize modern healthcare. The batteries used in devices implanted inside the human body are directly linked to the patient’s life, making reliability and safety a top priority. Recently, secondary batteries are powering advanced medical devices such as pacemakers, which replace the heart’s natural sinoatrial node***, and nerve stimulators. The application of secondary batteries in implantable medical devices is gradually becoming a reality. However, current limitations in battery capacity mean that replacement surgeries are still necessary after a certain period. Ongoing efforts are focused on addressing these power supply challenges.

***Sinoatrial node: generates electrical impulses that spread across the heart, causing the heart to contract and thereby regulating the rhythm of the heartbeat in mammals

🔍 [Robot Industry] Cutting the cords

Secondary batteries have brought game-changing advancements to the field of factory automation and industrial robotics. Now, robots are liberated from power outlets and cables, granting them enhanced mobility. In particular, the logistics sector has seen a skyrocketing demand for robots equipped with secondary batteries. These robots include those used in warehouses and ports for unloading, locating, and packaging goods, as well as those utilizing tracking functions to deliver food to restaurant patrons, known as AMRs (Autonomous Mobile Robots). Additionally, there are last-mile delivery robots that use AI to autonomously detect and respond to their surroundings, delivering items right to the customer’s doorstep. Thanks to advancements in secondary batteries, robots have been liberated from the constraints of power outlets, injecting new vitality into the industrial robot market.

| Transforming shapes for every need with versatile form factors

While both tiny batteries in wireless earphones and those powering large vehicles fall under the “secondary batteries” category, their shapes and properties vary significantly. This is because size and shape of the battery depend on the available space in the device, the battery’s energy density, and its capacity. For EVs, multiple cells are often combined into a single pack, with manufacturers adopting different designs. So, what are the features of different secondary battery form factors?

■ Classic battery form – Cylindrical batteries

Cylindrical batteries, resembling common household cells, are a classic choice in battery design. They use a jellyroll structure, with the cathode, anode, and separator rolled into a metal cylinder, filled with electrolytes, and then sealed. These batteries are cost-effective, easy to mass-produce, and offer a reliable supply. Although they feature high volumetric energy density, they have lower capacity and shorter lifespans compared to other types. This means multiple units must be bundled together for use in EVs, which drives up system costs.

■ Power in a box – Prismatic batteries

Shaped like a sleek rectangular box, prismatic batteries pack their cathode, anode, and separator layers inside an aluminum can. Although the round jellyroll structure inside the square case slightly reduces space efficiency, the aluminum shell enhances durability and resistance to external impacts. SK On unveiled a life-size model of the prototype of its prismatic battery at InterBattery 2023, highlighting its rapid charging capabilities.

Life-sized model of the prototype of prismatic battery, unveiled by SK On at InterBattery 2023

■ Batteries in a flexible film pouch – Pouch Batteries

Pouch batteries, encased in a flexible film pouch, offer versatility in size and shape compared to cylindrical and prismatic batteries. Instead of using jellyroll structure, the anode, cathode, and separator layers are stacked, maximizing internal space and boosting energy density. This efficient design, combined with ease of processing, allows for a variety of shapes, making them ideal for thin and wide design. These qualities meet the diverse needs of EV manufacturers seeking customized battery solutions for different models.

At InterBattery 2024, SK On, known for its expertise in pouch batteries, captivated the audience by unveiling its Advanced SF (Super Fast) battery, featuring impressive rapid charging capabilities. First introduced in 2021, the original SF battery, a high-nickel battery, can charge from 10% to 80% in just 18 minutes. The new Advanced SF model enhances this process further, increasing energy density by 9% while maintaining the same quick charging time. This increase in energy density results in longer driving ranges for EVs on a single charge.

Advanced SF (Super Fast) battery, one of the pouch batteries produced by SK On

■ Flat and round like a coin – Coin cell batteries

Coin cells, small coin-shaped batteries, are essential components for small electronic devices such as wireless earphones or medical devices. Their compact size means all essential battery components must fit into a very limited space while ensuring reliable performance. As wearable devices become more sophisticated, their power needs grow as well, driving efforts to boost the energy density of coin cells.

What’s next for secondary batteries, the unsung heroes that have revolutionized our quality of life? It might be towards batteries with even higher safety and energy density. Beyond mere convenience, the innovation in our modes of transportation, lifestyle patterns, and infrastructure, coupled with global efforts to tackle climate change, leads to the development of next-generation batteries such as solid-state batteries. These technological advancements will be more than just performance improvements; they will be the key to a sustainable future!

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin