Trends & Reports

Trends & Reports

Petroleum was discovered by chance in human history. However, its role as a significant energy source driving the development of human civilization is a result of technological advancements. How could humanity extract the petroleum stored in the ground? Among the numerous hypotheses, the prevailing opinion is that it likely originated from the method used to extract salt.

| From digging the ground to find salt

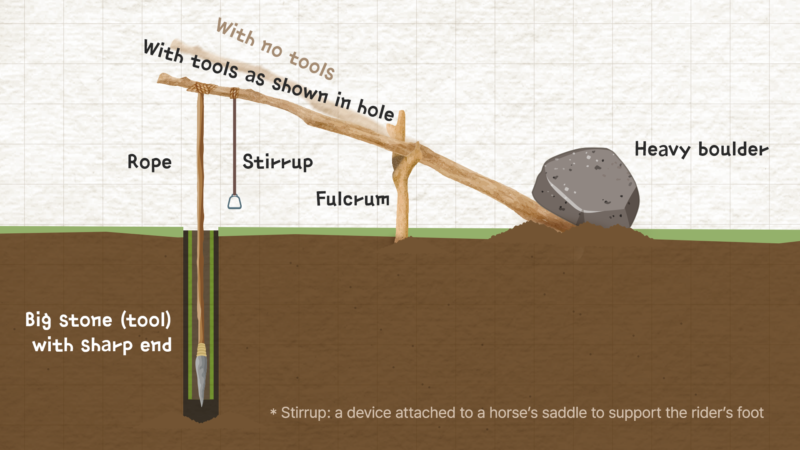

A long time ago, in Sichuan (四川), a province in Southwestern China, salt was difficult to obtain due to the rugged mountains. The most viable method for retrieval was to draw up high-salinity groundwater from wells and evaporate it. People used a percussion drilling method by attaching a sharp large stone to a pole with a rope, pulling it up using a lever principle, and then striking it down to the ground. As technology advances, it has been possible to drill up to a depth of 1 kilometer by using iron instead of a sharp stone and inserting bamboo to prevent a hole from collapsing.

Excerpt from the Tiangong Kaiwu Encyclopedia, written by Song Yingxing in 1637. Drilling for salt (Source: Wikipedia)

| How did China’s drilling technology spread widely?

In the late 1820s, French missionary Laurent Imbert visited China and first encountered Chinese drilling technology. He was captivated by the astonishing innovations and wrote detailed letters back to French scientists to introduce the methods, but was only met with strong doubt. Undeterred, Imbert conducted numerous experiments and ultimately succeeded in replicating the drilling technology, proving its feasibility and opening new horizons in the field. This achievement became a sensation in the French science community and spread throughout Europe. Meanwhile, this drilling technology was also introduced to the United States, primarily due to the Chinese laborers employed in railroad construction.

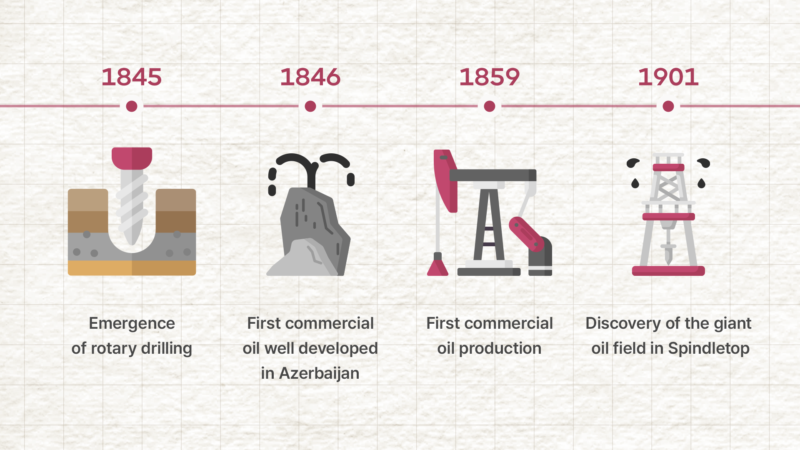

| The evolution and commercialization of oil drilling technology: A historical timeline

□ 1845: Emergence of the modern rotary drilling system

In 1845, with the ongoing advancement of drilling technology, British engineer Robert Beart created the modern form of rotary drilling. This method involved rotating a drill bit attached to the end of a rod, which required the use of drilling mud* to remove cuttings generated inside the borehole. Moreover, Beart developed the mud circulation system to enhance efficiency.

(*) Drilling mud: a water-based slurry used in rotary drilling, primarily for the removal of cuttings, maintaining well pressure, and keeping the drill bit from overheating.

□ 1846: World’s first commercial oil well, Bibi-Heybat

The world’s first commercial oil well was located near Baku, the capital of Azerbaijan, on the coast of the Caspian Sea. At the Bibi-Heybat oil field, the first drilling operation to develop an oil well was conducted in 1846, laying the foundation for commercial crude oil production. Remarkably, 178 years later, the Bibi-Heybat oilfield still contains crude oil.

□ 1859: Beginning of commercial oil production

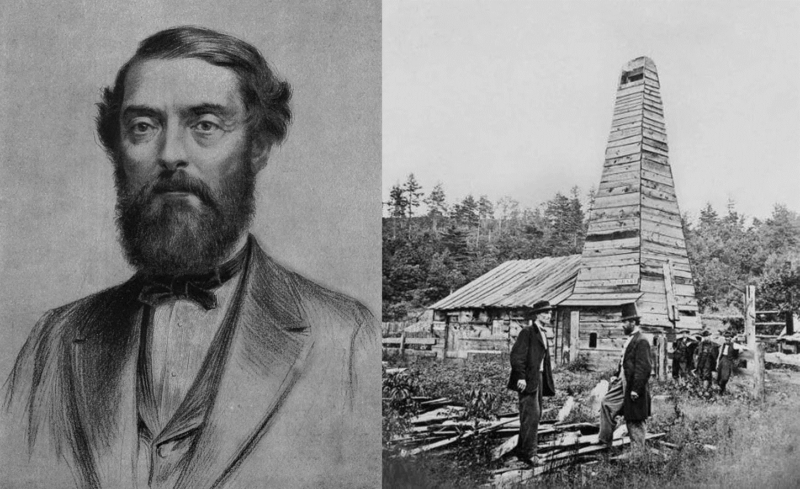

In 1852, Polish pharmacist Ignacy Łukasiewicz made a groundbreaking discovery by successfully separating kerosene from crude oil for the first time in history. A year later, while visiting his alma mater, Dartmouth College, American lawyer George Bissell stumbled upon crude oil samples in Professor Dixi Crosby’s lab. Realizing the potential to profit from using oil as lamp fuel, he first began to search for salt mines as he was inspired by the fact that salt miners often discovered oil while drilling for brine. He recruited investors and founded the Seneca Oil Company (later renamed the Pennsylvania Oil Company). This marked the transition from expensive candles and whale oil to kerosene for lighting. The person hired to take charge of drilling at that time was none other than Edwin Drake, an indispensable figure in the history of oil.

(Left) Edwin Drake / (Right) Drake Well in Titusville, Pennsylvania (Source: Wikipedia)

Edwin Drake spent a year and a half drilling in Titusville, Pennsylvania, using the salt-mining technology. Finally, on August 27, 1859, he struck oil at a depth of 69.5 feet (21.18 meters). This event signifies a major milestone in the history of oil as it was the first successful use of a steam engine-powered vertical drilling technique, akin to pounding the ground with a giant mortar and pestle. Within a year of this breakthrough, over 300 wells were drilled in Titusville alone, igniting an oil boom across the United States. The era of commercial oil production had officially begun.

□ 1901: Start of the Texas oil boom – Discovery of Spindletop oil field

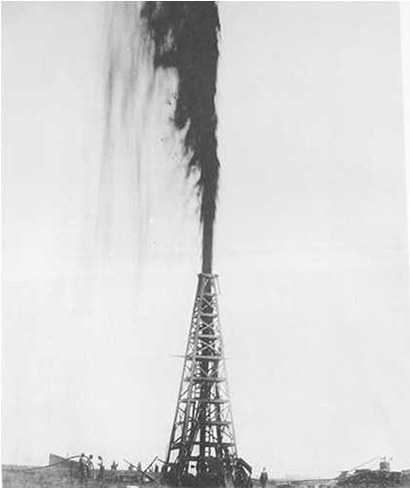

On January 10, 1901, a thunderous explosion erupted in the oil fields south of Beaumont, Texas, followed by a massive geyser of black liquid shooting into the sky. This spectacular sight was oil, marking the discovery of the Spindletop oil field, a landmark moment in the history of the modern oil industry. This event also signaled the beginning of the Texas oil boom.

The first successful large-scale oil drilling at Spindletop in Texas (Source: Wikipedia)

The Spindletop oil field produced an astounding 80,000 to 100,000 barrels of oil per day. This was a remarkable achievement, especially considering that typical oil fields at the time only produced 50 to 100 barrels per day. Such impressive output was achieved thanks to the rotary drilling method powered by Anthony Francis Lucas’s steam engine. Consequently, rotary drilling quickly became a standard practice worldwide.

| Understanding modern oil drilling techniques

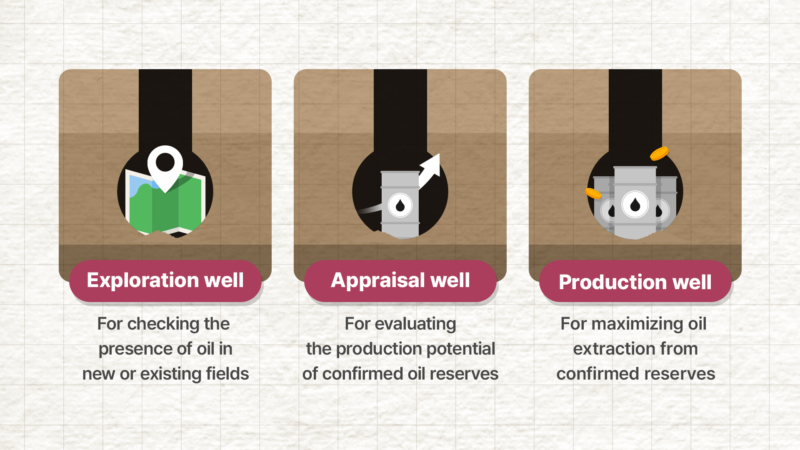

Today, we drill for oil using a variety of methods and techniques. Drilling can be divided into three types based on its purpose: exploration, appraisal, and production drilling.

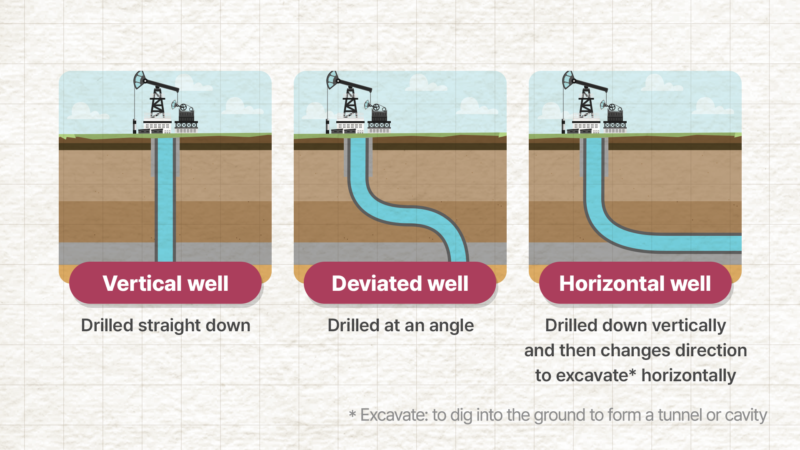

The orientation of the well depends on the location and characteristics of the reservoir, resulting in classifications such as vertical wells, deviated wells, and horizontal wells.

So how can we drill down to reach oil?

First of all, the drilling process for a basic vertical well involves penetrating the ground with a drill bit and bottomhole assembly attached to the end of a drill pipe. This continues until the required depth to install the first casing** is reached. At this stage, cuttings created during this process are carried to the surface and removed along with the drilling mud according to the mud circulation system.

(**) Casing: a metal casing inserted into the borehole with cement to prevent collapse due to increased pressure in the rock layers during oil drilling

Drilling mud, a mixture of fluids and various additives, is crucial for maintaining pressure and cooling the equipment. During exploration drilling, the rock cuttings brought up by the drilling mud are analyzed to determine the presence of oil.

After cleaning the borehole by the circulation of drilling mud, casings will be run in hole and cemented to secure the wellbore integrity against the formation pressure, allowing the well structure from the wellbore collapse. The size of the metal casing is gradually reduced in 2-3 stages until the desired depth is reached. This method allows the well to withstand high pressures at great depths and safely produce oil, eliminating potential risks.

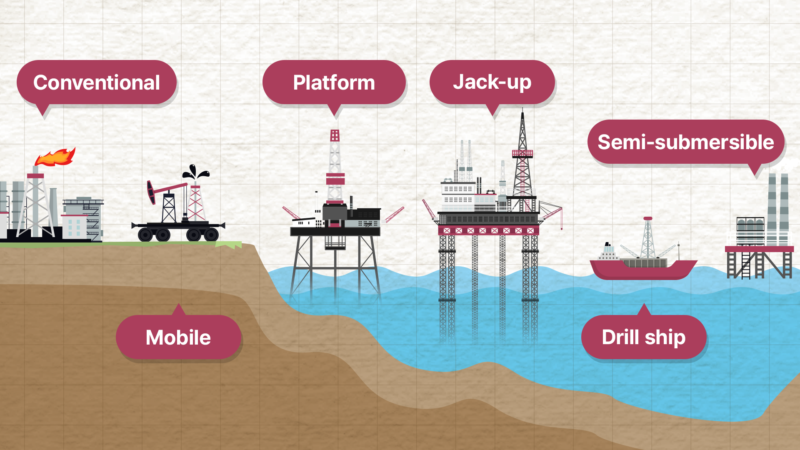

There are different types of drilling rigs depending on the application. Land rigs are divided into the Conventional Rig that are fixed to the surface and the Mobile Rig that are movable. Offshore rigs are divided into the Fixed Platform built on the seabed, the Jack-Up used in shallow waters less than 100 meters deep, the Semi-submersible used at deeper depths, and the Drill Ship that can sail on their own.

Three phases are implemented to recover oil. In the first phase, known as primary recovery, oil is initially extracted using the pressure difference between the surface and the underground reservoir or by using pumps. As the amount of oil in the ground decreases and production slows, high-pressure water is injected to enhance recovery, a method referred to as secondary recovery or water flooding. The last phase is called tertiary recovery, in which steam, gas, or chemical solutions are used to extract any remaining oil and maximize production.

Futuristic rendering of oil drilling on Mars (AI-generated image)

The upstream petroleum industry has made continuous progress. Since the 20th century, the predictions that oil would run out within a few decades have been made several times. However, advances in exploration, drilling, and production technologies have led to the discovery of new oil fields deeper underground and underwater. Additionally, unconventional resources like shale have been developed, resulting in an increase in the world’s proven oil reserves each year. In the future, if technological innovations in artificial intelligence (AI) and robotics, along with development in new areas such as Antarctica and the Arctic, advance further, wouldn’t the concerns about oil depletion be further alleviated?

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin