Trends & Reports

Trends & Reports

You might have bought a sleek, clear phone case that eventually turned dingy yellow, leading you to question if it’s because of your hands. Or maybe you’ve noticed seats at a sports stadium that look trampled on, causing you to wonder if someone stepped on them and feel uneasy about sitting down. Is it really just poor maintenance that causes plastics to fade? The truth is, there’s more to this than meets the eye—a hidden secret about plastics we often overlook.

| The mystery behind yellowed plastics

A clean phone case/mouse vs. a discolored phone case/mouse

Many of us have seen plastic “age” over time, such as when a clear smartphone case gradually turns yellow. This doesn’t happen only with TPU (Thermoplastic Polyurethane), the primary material for “gel” phone cases; it also occurs with ABS (Acrylonitrile Butadiene Styrene), which is used in computer keyboards and mice. A once-white keyboard slowly turning yellow is a familiar sight, as these materials naturally change color over time

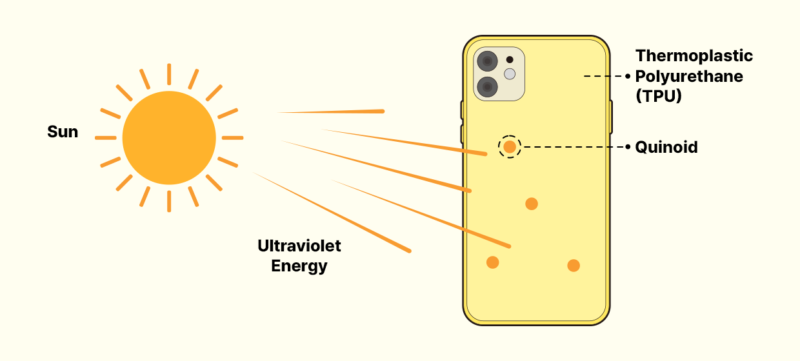

One commonly known cause of yellowing is ultraviolet (UV) rays. When plastics are exposed to sunlight, UV rays can alter existing color molecules or create new pigments, leading to discoloration. TPU, in particular, undergoes changes in its molecular structure when exposed to UV rays for extended periods. This process creates red molecules called quinoids, which gradually build up and turn the case yellow. Besides UV rays, prolonged exposure to high temperatures can weaken plastic’s stability, making it more prone to discoloration. This effect is often seen in electronic devices, where heat breaks down the molecular structure of plastics, causing them to change color over time.

Oxidation and contaminants are also key factors in plastic discoloration. Over time, plastics can react with oxygen in the air, leading to oxidative reactions, especially common in older plastics, resulting in yellowing. Additionally, external contaminants like dust and dirt can accumulate on the surface, causing visible discoloration. While cleaning can partially restore the appearance, it can’t fully bring back the plastic’s original condition.

| Why plastics lose their color: bending, fading, and more

So, do plastics only turn yellow? Not really—they can also turn white. This “whitening” phenomenon is common in thermoplastics*.

*Thermoplastics, also known as thermosoftening plastics, are high polymers that melt when heated and return to a solid state when sufficiently cooled, making them recyclable

When thermoplastics are bent or subjected to repeated pressure, their internal polymer structure shifts. These structural changes affect the material’s density and light refraction, causing the plastic to appear white. Think of a chewed-on plastic straw or an old credit card you bend before discarding—the stressed areas invariably turn white.

In addition to external pressure, weathering or sunlight can also cause plastic to whiten. A typical example can be seen in the seats installed in sports stadiums. These plastic chairs are often exposed to intense sunlight for prolonged periods. As a result, UV rays alter the color molecules in the plastic, causing them to lose their original appearance.

Moreover, moisture and extreme temperature changes can also trigger whitening. Some plastic materials naturally undergo this process over time. For instance, plastics used in products like cars often turn white due to direct sunlight, temperature fluctuations, and exposure to various pollutants that accelerate the aging process. These common scenarios illustrate how a variety of factors contribute to plastic discoloration.

| Techniques to preserve plastic’s original hue

Plastic discoloration isn’t just a cosmetic issue—it can also compromise a product’s performance, making it crucial to preserve and restore the original color of plastics. For instance, in the 1980s, car headlights were primarily made of plastic, but whitening caused by UV exposure reduced light transmission, impairing visibility during night driving and impacting safety. To address this problem, the automotive industry was motivated to improve plastic materials and develop UV-blocking coating technologies. So, what are the current technologies and methods available to prevent or restore plastic discoloration?

Various colors of TPU cases (source: EasyAcc)

Various methods have been developed to prevent plastic discoloration. Recently, efforts have focused on creating plastics with UV-blocking layers or incorporating materials that resist discoloration. For example, transparent smartphone cases often use polycarbonate for the back panel, which is relatively resistant to yellowing, while TPU is used only for the edges. In some cases, color is added to the TPU material to minimize noticeable discoloration. Additionally, “UV-blocking layers” and “overheating prevention layers” can be applied to prevent discoloration caused by UV rays and heat generated by smartphones.

There are also various ways to restore discolored plastics. For example, if a computer keyboard or mouse has yellowed, applying diluted hydrogen peroxide and exposing it to direct sunlight or a UV lamp can restore its original white color. This method works by utilizing the bleaching effect of hydrogen peroxide, which reacts with the stained molecules on the plastic surface.

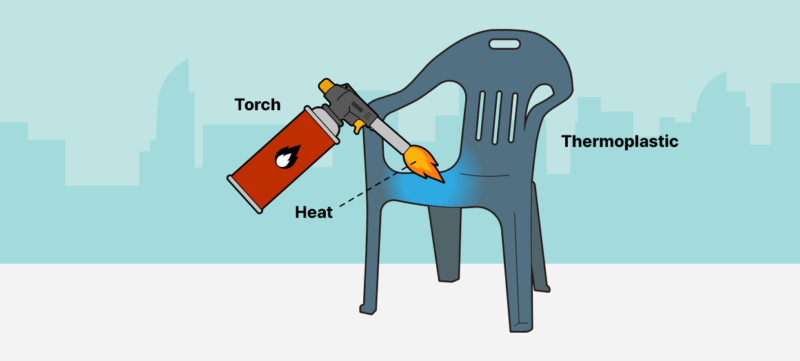

Another method to whiten plastic involves using a torch. This technique is applicable for thermoplastics and is commonly used to restore seats in sports stadiums. By carefully applying a hot flame to the discolored seats, the thin UV-damaged surface layer burns away, revealing the intact layer underneath and making the plastic appear as if it has regained its original color.

Plastic discoloration can occur for various reasons, but there are many ways to address this issue. Because changes in color can affect both product performance and the user experience, the industry is continuously developing technologies to prevent discoloration and searching for more durable materials. These efforts result in the creation of better products. It’s exciting to think that UV-resistant and fade-proof plastics may soon become a standard part of our everyday lives.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin