Trends & Reports

Trends & Reports

Following up on the first episode of Secondary Batteries Quick Note, this time we are going to explore the all-solid-state battery. Boasting high safety and energy density, all-solid-state battery has become the most notable next-generation secondary battery, and it is dubbed the “dream battery”. So what exactly is an all-solid-state battery, and why it is called a dream?

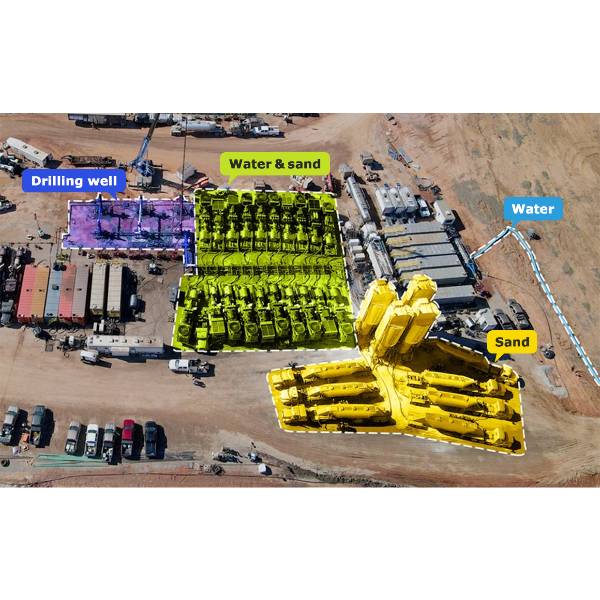

SK On’s all-solid-state battery unveiled at InterBattery 2023.

| What is an all-solid-state battery?

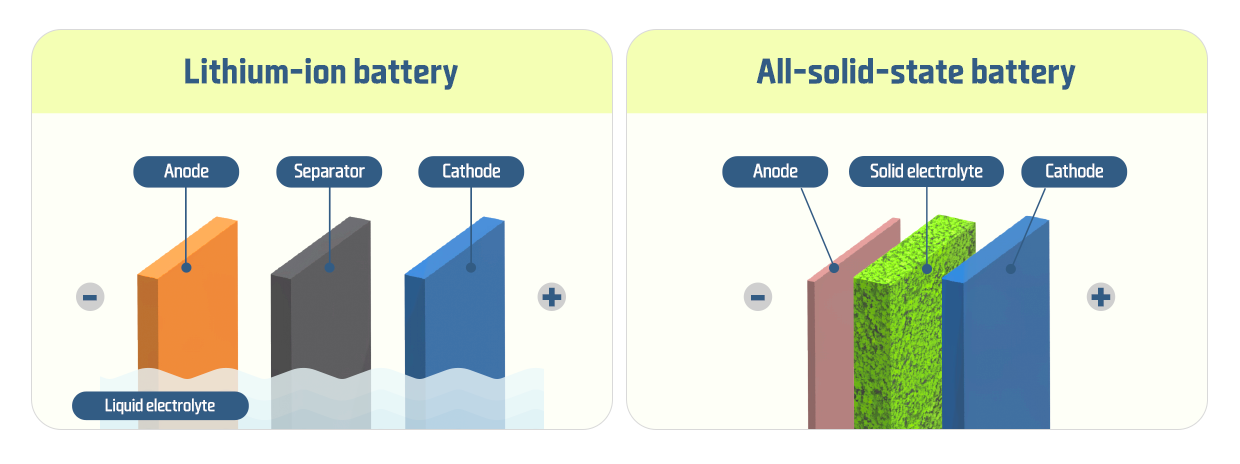

As introduced in the previous post of this series, the basic structure of a secondary battery consists of electrodes (anode and cathode), electrolyte, and separator. Most existing secondary cells, including lithium-ion (Li-ion) batteries use liquid electrolyte that transport ions between the electrodes, so a separator is crucial to prevent physical contact between the anode and cathode. What makes the all-solid-state batteries different from those battery, first of all, lies in the type of electrolyte. The “solid” part in the name of all-solid-state battery indicates that it uses solid electrolyte instead of liquid type, and thus it does not need a separator to prevent short-circuiting between the anode and cathode.

| Advantages of all-solid-state batteries

Li-ion batteries can be prone to the dendrite formation phenomenon. Dendrite means tree-branch-like crystalline structures that accumulate on the surface of the cathode during charging and discharging. If these structures grow enough to penetrate the separator and reach the anode, internal short-circuits can occur, leading to the risk of fire. All-solid-state batteries address this issue by applying a non-flammable solid electrolyte to block lithium dendrite growth, effectively eliminating one of the main causes of fire accident. Therefore, all-solid-state batteries are expected to enhance the stability/safety of secondary cells.

In addition, all-solid-state batteries can improve energy density by packing more active materials into the anode and cathode instead of using a separator or by utilizing high-capacity anode materials. Active materials refer to the active substance in the electrodes of a battery that produces electrical energy through chemical reactions. A battery’s energy storage capacity increases with a higher amount of active material.

| Why all-solid-state is a “dream battery”

With increased safety, higher energy density, and reduced weight and volume, all-solid-state battery is indeed the most anticipated type of next-generation secondary cells, but it is still a “dream” despite of the ideal features due to some certain reasons.

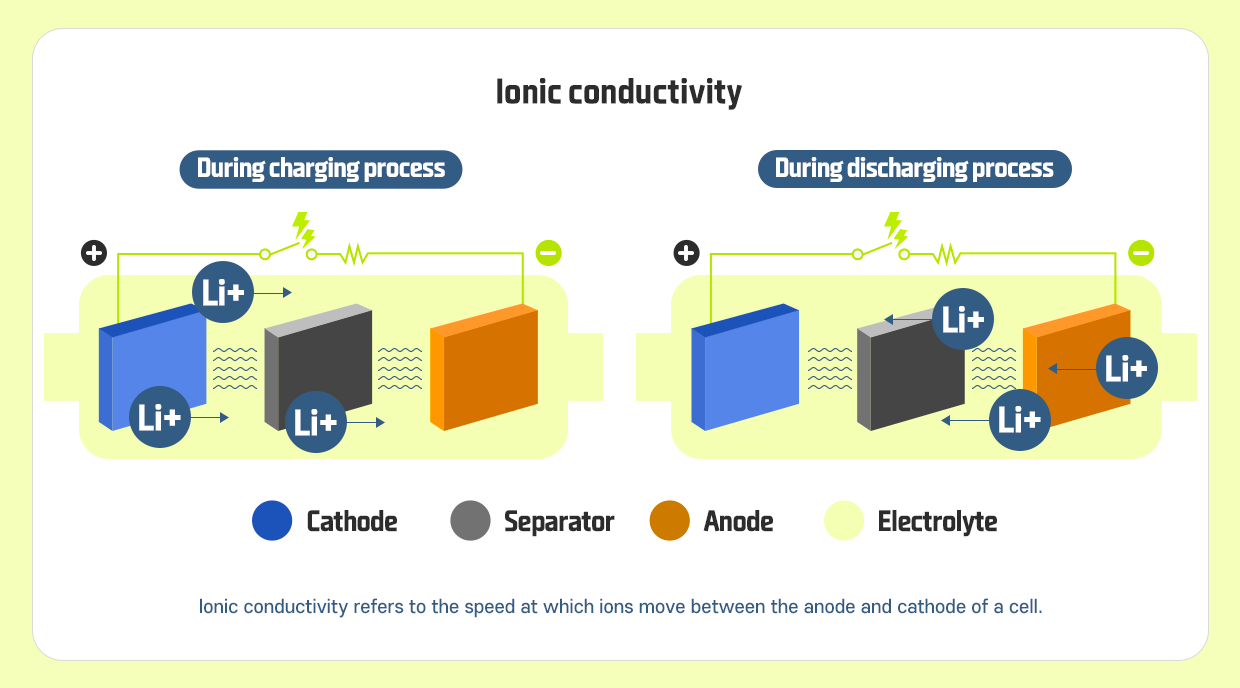

The ionic conductivity of the solid electrolytes used in all-solid-state batteries is lower than that of the liquid electrolytes used in Li-ion batteries. The higher the ionic conductivity, the greater the battery’s output (the amount of electricity a battery can deliver per unit time), and the faster it can be charged. All-solid-state batteries face the issue of interface resistance, which occurs when the solid electrolyte and electrodes are not perfectly in contact, leading to high resistance and thus reducing ionic conductivity. It is just like how it is harder to move through a ball pit (solid) than through a swimming pool (liquid).

Additionally, the production cost of all-solid-state batteries are higher than Li-ion cells. It is because they have more expensive raw materials and complex manufacturing process.

| Types of all-solid-state batteries

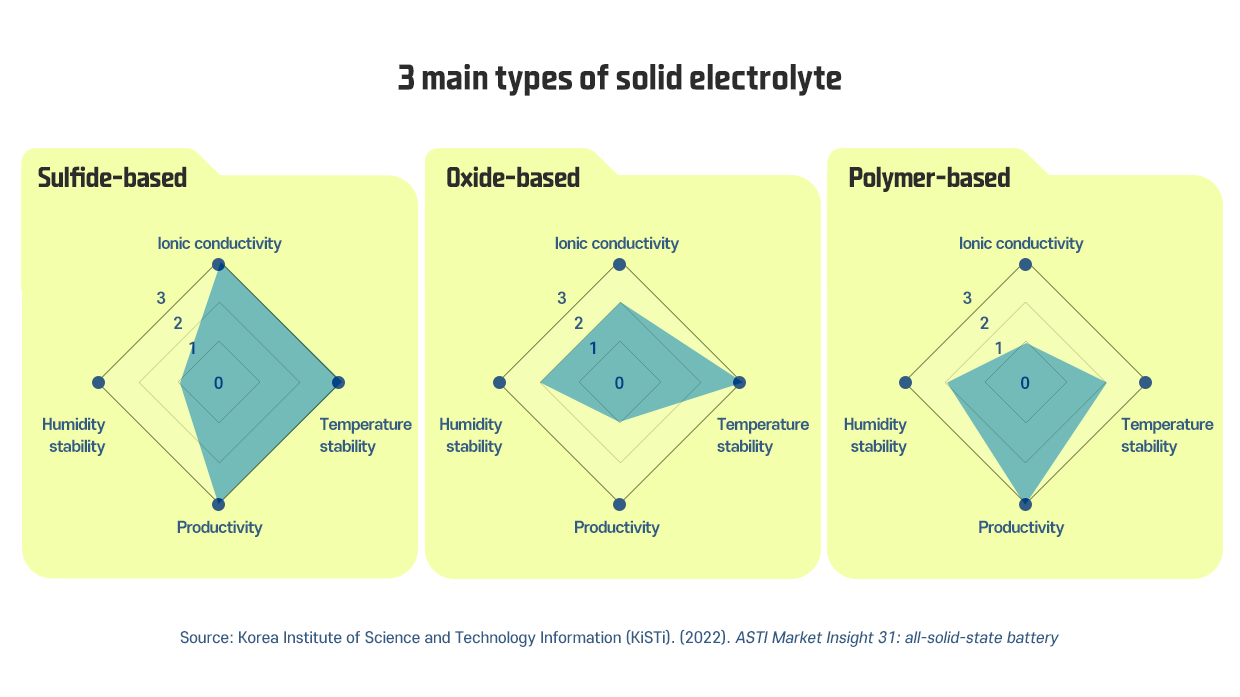

The key to commercializing all-solid-state batteries lies in the development of solid-state electrolytes, which can be classified based on the raw materials into sulfide-based, oxide-based and polymer-based categories.

Sulfide-based all-solid-state batteries, which are lightweight, are anticipated to be used in electric vehicles and for military and space industry. Meanwhile, oxide-based solid-state batteries, known for their high-temperature stability, are expected to be utilized in Energy Storage Systems (ESSs) and similar applications.

| All-solid-state battery market trends

All-solid-state batteries are predicted to account for 10-13% of the total battery market by 2035, with the market size expected to reach 149 GWh (gigawatt hours) by 2030 and 950 GWh by 2035, according to a report released by SNE Research in 2023.

In South Korea, the government is supporting technological research and development for the commercialization of all-solid-state batteries, in collaboration with related manufacturers including SK On.

| SK On’s endeavors in realizing all-solid-state batteries

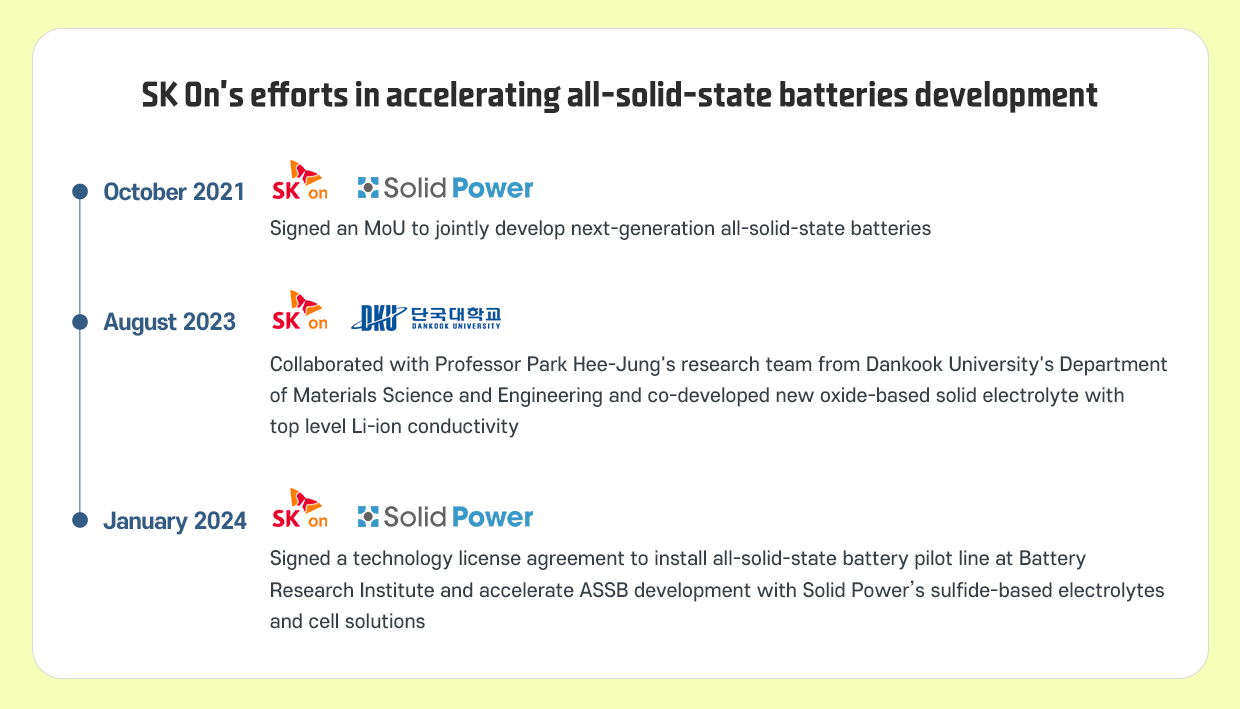

SK On is dedicated to furthering its research and development infrastructure for next-generation batteries, including all-solid-state batteries, through strategic investment and collaborations. In January 2024, SK On signed a research and development technology license agreement with Solid Power, a U.S.-based leading developer of solid-state battery technology. Through this agreement, SK On plans to establish an all-solid-state pilot line at its Battery Research Institute in Daejeon, South Korea, by 2025.

The history of secondary batteries that began in the 19th century will turn to another significant page once the all-solid-state batteries are commercialized, and that day is coming soon.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin