SK Innovation

SK Innovation■ New material to upgrade battery power density, charging speed

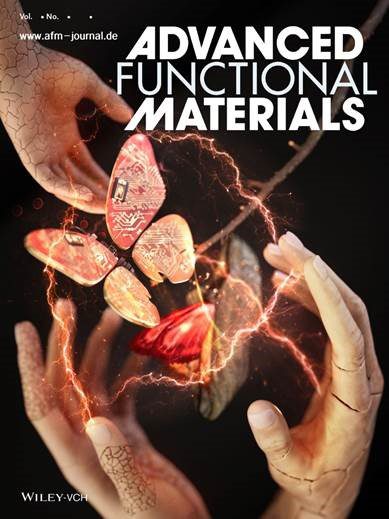

■ Co-development with Dankook University published as cover article in renowned science journal; patent application for technologies completed

On August 31, SK On, a leading electric vehicle (EV) battery manufacturer, announced it has successfully co-developed a new oxide-based solid electrolyte boasting a top-notch lithium-ion conductivity.

Lithium-ion conductivity refers to the movement speed of lithium ions. Faster speed results in greater battery performance and quick charging time. SK On expects the latest development to boost its competitiveness in all-solid-state batteries.

SK On said that the research results related to this oxide-based solid-state electrolyte, co-developed with Professor Park Hee Jung’s research team from Dankook University’s Department of Materials Science and Engineering, were published as a cover article in the globally renowned academic journal “Advanced Functional Materials (IF 19.9).” The joint research team of SK On and Dankook University have also completed the patent application process for this technology both domestically and internationally.

The newly developed solid-state electrolyte not only significantly improves lithium-ion conductivity but also ensures air stability. The joint research team improved the lithium-ion conductivity by 70% to the world’s top level (1.7 mS/cm, millisiemens per centimeter) by adjusting the additive material in the oxide-based solid-state electrolyte material Li-La-Zr-O (Lithium-Lanthanum-Zirconium-Oxygen or LLZO).

An increase in lithium-ion conductivity generally compromises stability, but the research team overcame this issue through good control over the microstructure of LLZO. Typically, solid-state electrolytes are vulnerable to moisture (H2O) and carbon dioxide (CO2). Under prolonged exposure to the atmosphere, their functionality as electrolytes deteriorates. However, this particular solid-state electrolyte exhibited outstanding stability.

Oxide-based solid-state electrolytes have lower ionic conductivity compared to their sulfide-based counterparts, but they offer superior chemical stability. This minimizes reactivity with anode materials and can suppress the lithium dendrite formation*, thereby enabling the replacement of graphite cathodes with high-capacity lithium metal.

(*)Dendrite: Tree-branch-like crystalline structures that accumulate on the surface of the cathode during charging and discharging. If these structures penetrate the separator and reach the anode, internal short-circuits can occur, leading to the risk of fire.

The battery capacity can increase significantly as well. While the maximum operating voltage for lithium-ion batteries (LiB) that use liquid electrolytes is up to 4.3V, that of oxide-based solid-state electrolytes can be extended up to 5.5V. Theoretically, this could result in a 25% increase in battery capacity.

This solid-state electrolyte can be applied to not only NCM cathode-based solid-state batteries, but also to next-generation batteries, such as lithium-sulfur and lithium-air batteries. Like LiB, these next-generation batteries under development currently use liquid electrolytes, but it is expected that the application of this solid-state electrolyte enables them to be made into all-solid-state batteries.

Additionally, the material can also be applied to SK On’s high-molecular-oxide-based composite solid-state batteries that are currently under development. As oxide-based solid-state electrolytes possess mechanical properties that are superior to high-molecular ones, this application can effectively overcome the limitations of high-molecular all-solid-state batteries, such as the dendrite formation.

Therefore, if this new electrolyte is applied to next-generation batteries, it is possible to satisfy needs of both fire safety and extended driving range.

Choi Kyoung-hwan, Head of SK On Next Generation Battery R&D Office, said, “This solid-state electrolyte, which has both ionic conductivity and atmospheric stability, will have a substantial ripple effect as an innovative technology for creating high-quality all-solid-state batteries.” He added, “Based on our superb future technological competitiveness, SK On will continue to forge growth opportunities in the field of next-generation batteries.”

Meanwhile, SK On is in development of two types of all-solid-state batteries, which are high-molecular-oxide composite batteries and sulfide-based batteries. The company targets to produce early prototypes of both types by 2026 while aiming to commercialize them by 2028.

A next-generation battery pilot plant currently under construction at the Daejeon Battery Research Institute is expected to be completed next year.

[Photos]

(Photo 1) The cover of Advanced Functional Materials (AFM), a world-renowned academic journal containing the research results of a new oxide-based solid electrolyte jointly developed by SK On and Dankook University. LLZO, an oxide-based solid electrolyte material with controlled microstructure, is portrayed through the hands. The small skin structure (domain) on the left hand indicates small particles of solid electrolyte and the young skin indicates excellent atmospheric stability. The meaning that solid electrolyte is the core material of all-solid-state batteries was symbolized in the shape of electricity being produced in the hand. The red robot butterfly contains the image of the future in the SK logo.

(Photo 2) SK On’s high-molecular composite all-solid-state battery unveiled at InterBattery exhibition 2023 last march.

(Photo 3) SK On developed all-solid-state battery that was unveiled at InterBattery exhibition 2023 last March. SK On is developing two types of all-solid-state batteries, high-molecular-oxide composite and sulfide-based, with the goal of producing early-stage prototypes in 2026.

– SK On presents next generation technologies under the theme of “Move On” at InterBattery 2023

– SK On to unveil prismatic battery cell model at InterBattery 2023

– [CES 2023] Into the 1nnovation! ② Next-generation EV batteries development and related services expansion with partners

– How Solid State batteries will impact the future of automotive

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin