SK On

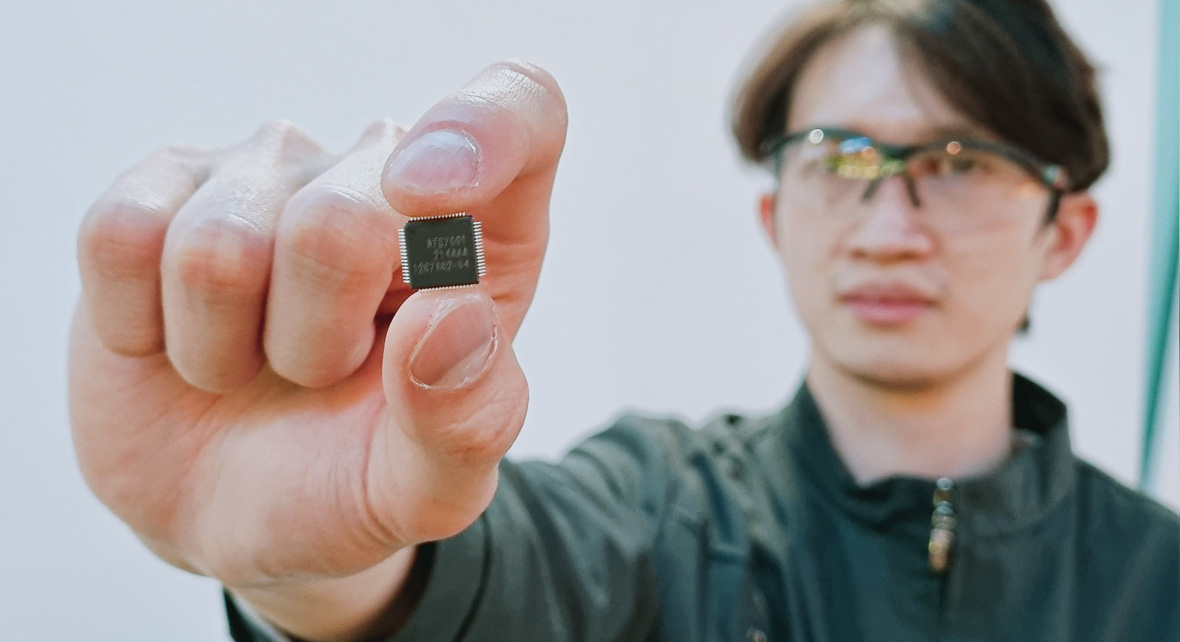

SK On■ SK On co-developed Battery Monitoring Integrated Circuit (BMIC), the integral semiconductor for battery management, with Autosilicon.

■ 10 BMICs installed per one electric vehicle (EV) as integral part for monitoring and pre-sensing abnormalities

On April 4, SK On announced that it has successfully developed Battery Monitoring Integrated Circuit (BMIC) with Autosilicon, a Korean fabless semiconductor company for automotive electronics. Through this, the company expects to enhance the safety and cost effectiveness of EV batteries while also stabilize the supply chain that fully relied on imports.

BMIC is a key component in battery management system. It improves the safety of the battery and, at the same time, increases charge efficiency. To do so, it monitors the voltage and temperature of hundreds of battery cells equipped in an EV or energy storage system (ESS). It detects a battery cell showing abnormalities and supports the battery management system (BMS) to control it. In short, the BMIC determines the performance of the battery management system. The chip’s price portion in the overall BMS is about 30%. It is also a core semiconductor that is installed in more than 10 units per EV.

The BMIC jointly developed by SK On and Autosilicon possesses a high level of quality and safety. It acquired Automotive Safety Integrity Level (ASIL-D), the highest level of international standard for the functional safety of road vehicles.

When compared to existing chips, it lessens the margin of error of the voltage measurement by half. Therefore, the chip enables the BMS to make an accurate decision to control abnormal situations effectively. Moreover, it demonstrates exceptional safety with unparalleled reliability as it runs at a high temperature of 125 degrees Celsius.

In addition, the chip is designed to continuously monitor the status of battery cells in time of emergency, even if a part of BMS functions does not work due to unexpected causes. It also applies a high-speed communication protocol that can transmit data up to two times faster than existing products while reducing the required number of components by half.

With this co-development, SK On has secured a stable supply of a core component that heavily relied on imports. This means the company can be self-sufficient from now on.

SK On and Autosilicon have been cooperating since 2019 to research and develop the BMIC that can enhance safety, performance and cost effectiveness. The BMIC developed through this collaboration will be supplied exclusively to SK On for a certain period.

“We plan to further enhance the safety of the battery through continuous technological innovations,” said Rhee Jang-weon, Head of SK On Battery R&D Center. He added, “We will solidify our position as a global top-tier battery company by our endeavor to pursue innovation.”

[Photo] Battery Monitoring Integrated Circuit (BMIC) developed by SK On

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin