SK On

SK On

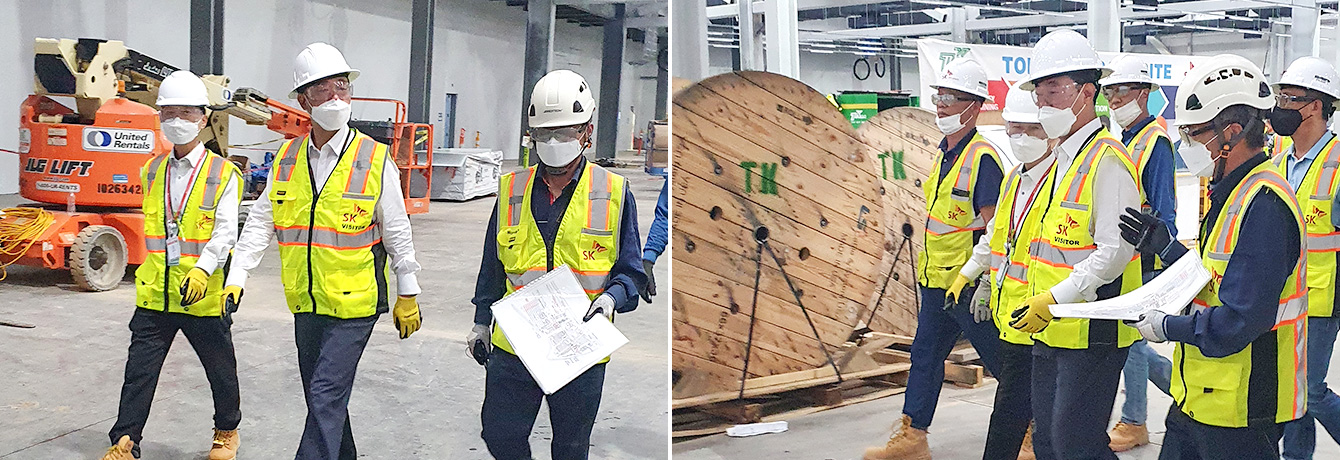

On September 29 (US local time), Jee Dong-seob, President of SK Innovation’s Battery Business, paid a visit to SK battery America (SKBA) in Georgia, USA to inspect the manufacturing facility and encourage local employees. President Jee’s visit was after the day he attended the announce events of Ford and SK Innovation’s joint venture BlueOvalSK’s production plant sites and large-scale investment plan in Tennessee and Kentucky.

During his visit to SKBA, President Jee received a direct report on SKBA’s Plant 1, which is running trial production and preparing for full-scale operation at the end of this year. President Jee also toured the second plant, which has finished more than 60% of the construction progress. In particular, President Jee kept emphasizing that safety is the top priority for his members.

▲ President of SK Innovation’s Battery Business Jee Dong-seob (second from the left) visits SKBA’s plants located in Georgia, USA on September 29 (US local time).

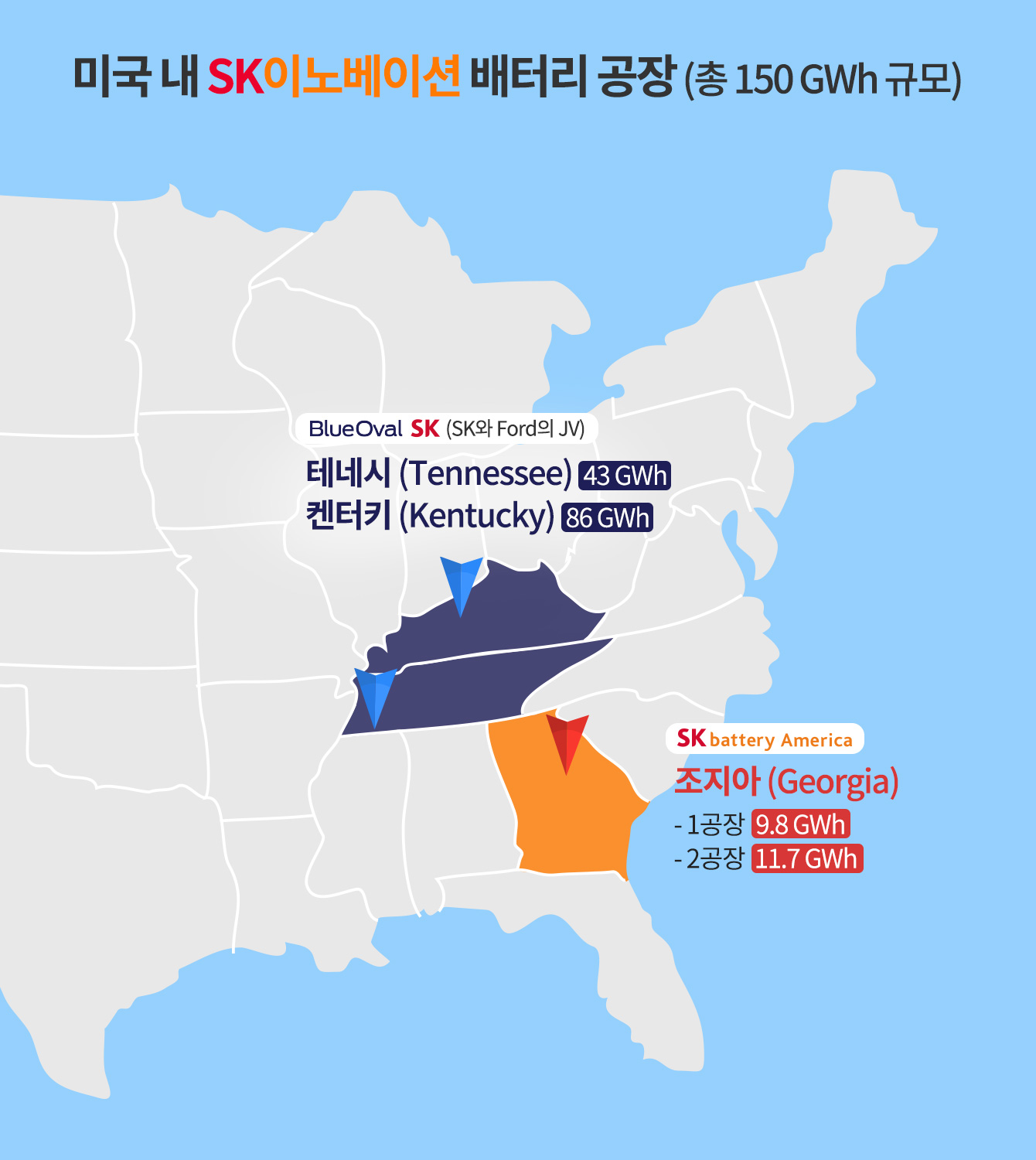

The annual production capacity of SKBA’s Plant 1 located in Georgia is 9.8 GWh and the production is ready to roll as scheduled despite the unprecedented Covid-19 situation. The EV batteries produced here will be mounted to Volkswagen’s ID.4 US-Version model and Ford’s F-150 Lightning Electric Truck model. Ford’s F-150 Lightning is especially prominent as this mega-hit model has attracted over 120,000 reservations since its unveiling in May.

▲ SKBA is located in Jackson County, Georgia, USA

The Georgia Plant 2 with a scale of 11.7 GWh that broke ground July last year and is to produce NCM9, a type of battery that contains 90% nickel and the entire output will be used in Ford’s F-150 Lightning model. The construction is underway without a glitch, and mechanical construction is expected to finish by August next year. Mass-production is scheduled to start in 2023 after taking a pilot production as early as late 2022.

After checking the construction site of Plant 2 with the construction staff, President Jee called a special session to encourage local members. He received a report on the production status and quality test results of the 1st plant in Georgia at the conference joined by local battery production/quality staff.

At the meeting, President Jee said, “Though the Covid-19 and tight schedule make it even more challenging, I sincerely would like to ask you all to pay extra attention to facility stabilization, operation rate, and process improvement before launching this factory.”

▲ (Left) President of SK Innovation’s Battery Business Jee Dong-seob (first from left) attends a meeting with SKBA members and encourages them during his visit at SKBA on September 29 (US local time). / (Right) Presidents Jee listens to the reports on battery production status from the members in charge of production and quality control

Scheduled to open late this year, SKBA’s Plant 1 in Georgia will rise to the top in terms of EV battery production capacity in the U.S. Furthermore, when the 2nd plant is completed in 2022, the total production capacity of SKBA’s EV battery plants in Georgia will total 21.5 GWh, solidifying its position as the global top tier company.

Moreover, SK Innovation announced its plan to build battery production plants of BlueOvalSK, a joint venture enterprise with Ford Motor Company in Tennessee and Kentucky, respectively. The Tennessee plant will sit on and share about 3,600 acre site with Ford’s EV production plant and have an annual production capacity of 43 GWh. The one in Kentucky will occupy about 1,500 square meters with a production capacity of 86 GWh per year (two 43 GWh units). This will mark a sum of 129 GWh scale for battery facility investment. This investment was the biggest ever investment made by SK Innovation and Ford and drew keen attention as it was also the largest investment ever in the history of both Tennessee and Kentucky. Adding SKBA’s production capacity of the EV battery plant in Georgia, SKBA will secure an annual capacity of more than 150 GWh all in all

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin