SK Earthon

SK Earthon■ Set off to introduce pyrolysis oil to processes from late September with an eye on establishing a circular economy for plastic waste

– Converting plastic waste to eco-friendly fuel oil utilizing a post-processing technology for removing impurities is part of the company’s Green Transformation strategy

■ Interests and support from the government such as the MOTIE and MOE play a pivotal role, its environmentally-friendly potential led to a ‘regulatory sandbox’ approval

■ CEO of SKGC Na Kyung-soo: “Our pioneering adoption of pyrolysis oil can be best understood as the product of public and private cooperation, we will nurture the ecosystem in cooperation with government agencies, business circles, and academia to establish a circular economy for plastic wastes”

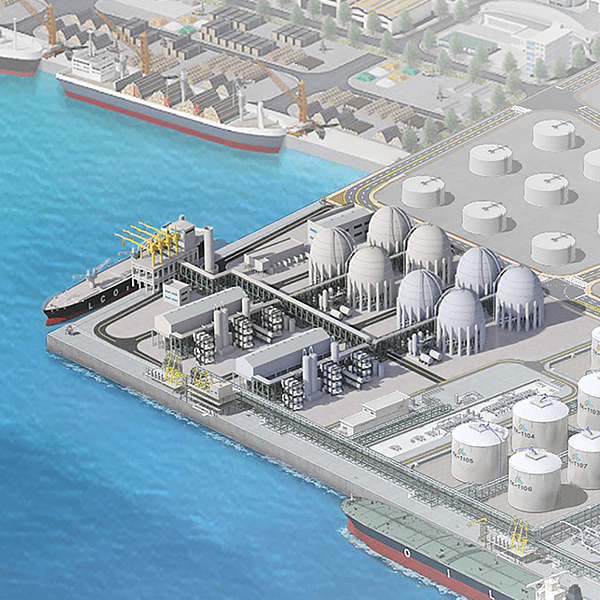

SK Innovation Ulsan Complex (hereafter “Ulsan CLX”) will be the first in South Korea to introduce pyrolysis oil as the material for the refinery/petrochemical process. Aside from its innovative approach as a solution to waste plastics, what makes this advancement more striking is that it was the fruit of the concerted public-private cooperation in building a circular economy for plastic wastes.

SK Geo Centric (SKGC) has announced that from late September onward, it will employ pyrolysis oil produced through the thermal degradation of plastic wastes as feed-stock oil to its refinery/petrochemical process in Ulsan Complex for the first time in Korea. Just like other crude oil, the pyrolysis oil employed as feed-stock oil will be reborn as a petrochemical process through the refinery process of SK Energy and the petrochemical process of SKGC.

It underscores the first step of SKGC’s Green Transformation strategy to grow as the world’s biggest ‘urban oil field company’ that produces petroleum by recycling plastic wastes originated from petroleum. It will substantially contribute to tackling the problem of plastic wastes in South Korea.

So far it was impossible to employ the existing pyrolysis oil as a raw material for petrochemical products as impurities such as chlorine might turn it into a source of air pollutants or a cause for facility corrosion. Building on the its inherent forte as a well-versed enterprise in the petrochemical business, SKGC developed and applied a post-processing technology to eliminate foreign objects from pyrolysis oil, thereby converting it into eco-friendly feed-stock oil.

The pyrolysis oil first adopted this time is from Jeju Clean Energy, a Korean pyrolysis enterprise that has been engaged in a joint research project on post-processing in conjunction with SKGC and SK Innovation’s Institute of Environmental Science & Technology since 2019. With a view to promoting co-prosperity and cooperation with the domestic SMEs (small and medium enterprises) in eco-friendly undertakings, SKGC will use the pyrolysis oil from the company and keep on expanding its use as feed-stocks for the oil-refinery and petrochemical processes after making some quality improvements.

Considering the urgent need of solving of waste plastic issues, SKGC also realized the necessity of acquiring a core pyrolysis technology and, thus, looks to administer a two-track strategy that involves securing a key pyrolysis technology through a global technology partnering and concomitantly constructing a large pyrolysis plant that combines SK’s own impurity removing process.

To do so, SK Geo Centric concluded an MOU on business cooperation with Brightmark, an US company that specialized in pyrolysis earlier this year, and announced its plan to build an urban oil field that runs based on chemical recycling methods such as a large-scale pyrolysis plant last July. The pyrolysis plant that integrates global technology with its own is scheduled for commercial operation in 2024 and is able to handle 200,000 tons of plastic wastes a year.

Yoo Jae-young, President of Ulsan CLX pointed out, “Despite eco-friendly characteristics of pyrolysis oil out of plastic waste, technical issues have always stood in the way of applying it to the process.” “It was a concerted effort and cooperation among the related departments and our six decades of experience and know-how in petrochemical business that made it possible to come up with the optimum solution and use the oil in actual processes.”

SKGC especially accentuated that the government agencies’ interest and support played a significant part in the successful application of Waste Plastic Pyrolysis Oil (WPPO) to the refinery process of SKE and the petrochemical process of SKGC.

According to the current Wastes Control Act and Petroleum and Alternative Fuel Business Act (hereinafter PAFB Act), it is not permitted to use Waster Plastic Pyrolysis Oil (WPPO) as a raw material for the petrochemical process for WPPO has not yet been recognized as an alternative fuel to petroleum. However, the government lifted the ban.

Earlier this year, hence, SKGC took advantage of a regulatory sandbox system and applied for ‘special regulation for substantiation’ to demonstrate how pyrolysis oil can be used as a raw material for process in SK’s plant. In the course, the relevant government agencies such as the Ministry of Trade, Industry, and Energy (MOTIE) and the Ministry of Environment (MOE) recognized the mitigating effect of the development project of process materials from pyrolysis oil on GHG and soil pollution as an alternative to incineration or landfilling and subsequently made a final decision to approve it about the middle of this month.

SKGC will gradually increase the amount of pyrolysis oil used in processes from approximately 200 tons/year or more and conduct empirical research on its effect on production facilities and products, and depending on the result, MOTIE will be in pursuit of amending the pertinent laws such as PAFB Act.

“The pioneering application of pyrolysis oil to the Ulsan CLX is the sheer product of joint public-private endeavor to promote a circular economy for plastic resources and environmentally-friendly initiatives,” said CEO of SKGC Na Kyung-soo. “We will beef up our cooperative ties with the relevant ministries, industries, and academia so as to make a grand transformation from Carbon to Green business based on ESG management.”

[Photos]

SK Innovation Ulsan CLX and SK Geo Centric members take commemorative photos in front of a tank truck loaded with waste plastic pyrolysis oil

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin