SK On

SK On

Through the first part of the speech presented by Head of SK Innovation’s Cell Development Center Lee Jon-ha, he has pointed out the main causes that could lead to fire accidents in EV batteries. To prevent such accidents, SK Innovation has been applying “innovative manufacturing technologies”. Let’s find out what they are through the second part of Lee’s speech.

Part 2: SK Innovation’s innovative EV battery manufacturing technologies

ㅣ Could you explain more about SK Innovation’s “innovative manufacturing technologies?”

Let me tell you about them one by one.

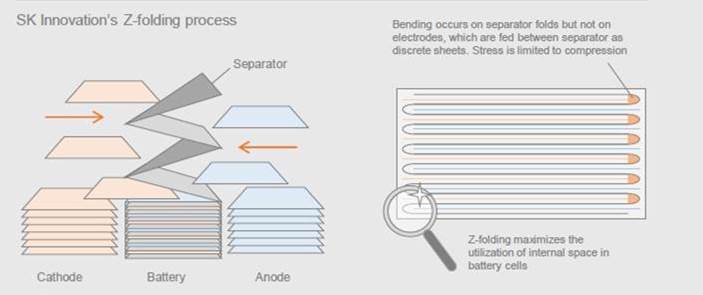

When stacking the separators inside the battery, SK Innovation uses the Z-folding technology.

Like I’ve briefed earlier, the conventional battery manufacturing method repeatedly stacks dozens of battery components that are like paper sheets in the order of anode-separator-cathode-separator, and then seals it with a pouch film (case). Another way is to sequentially overlap components of anode, separator, and cathode that are spread out in a long line, roll it up, and cover it with packing material. Unless this process is precise, the edges of the anode, separator, and cathode stacked on top of each other may not be neatly aligned.

However, the “Z-folding” technique implemented by SK Innovation pulls it out lengthwise without cutting out the separator, and it wraps the anode and cathode at once. In metaphoric terms, it is like pulling out a roll of tissue paper (separator) without breaking it, placing a red-colored paper (anode) on top of the tissue, then covering the red-colored paper with tissue from right to left. A blue-colored paper (cathode) is placed on top of the tissue paper, and the tissue paper is placed on the blue-colored paper from left to right. The process is repeated in a zigzag (z-shape) manner.

This way, the separator zig-zags through the anode and cathode and wraps them with perfect alignment, and therefore it allows complete separation. Through this, the possibility of anodes and cathodes coming in contact at the edges can be reduced remarkably and it also allows precise manufacturing in a high-speed production system, which in turn secures safety. In addition, if a vehicle’s speed goes up, the battery component’s alignment can be distorted. However, “Z-fold” does not carry such problems, so safety can be enhanced even more.

As I said earlier, we apply overlapping separators, so the alignment safety is excellent in high-speed systems as well. Our manufacturing speed in the current battery processes is 2.3 times faster compared to 2009, but we have not seen any issues.

▲ SK Innovation’s Z-folding technology

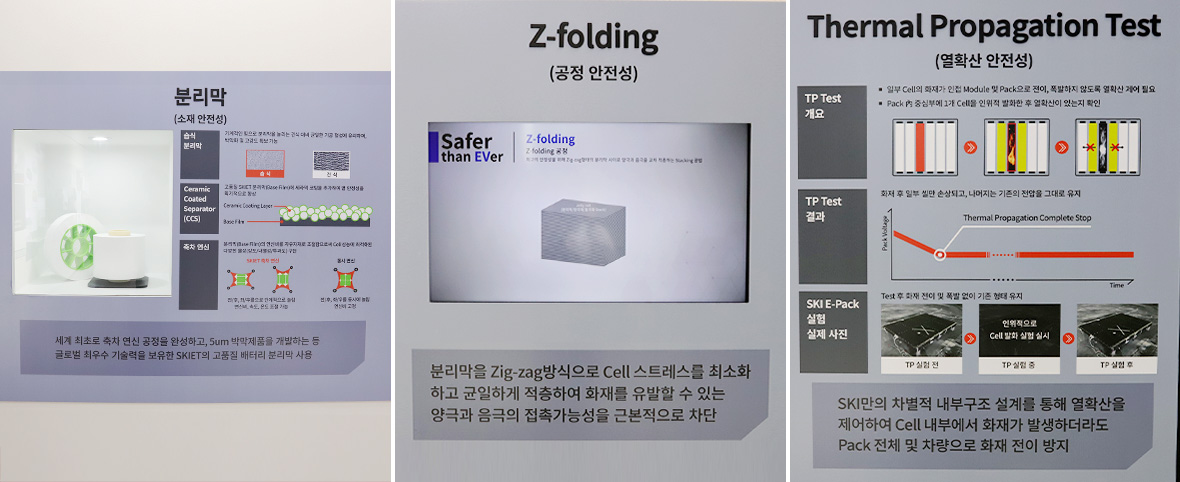

ㅣ You mentioned that one of the core technologies of batteries exclusive to SK Innovation is the “separator.” Please tell us more about it.

There are dozens of stacked anodes and cathodes inside a battery cell. As I said, physical contact between the anode and the cathode can cause a strong chemical reaction, which can cause fire. As such, a film called separator is placed between the anode and cathode so as to prevent short-circuiting inside a battery, which is another cause of fire. And at the same time, it provides channels for ions to move between the electrodes, thereby helping a battery to do its work. Separators have minuscule holes that can only be seen with a microscope.

The thinner the separator, the better the battery performance. This is because the ions are able to move even more actively between the anode and cathode. The easier the ions’ movements, the higher the battery output, and the faster the recharging speed. Yet, the problem is that a thin separator tends to be vulnerable to heat. So, when a battery is overheated, a thin separator is likely to shrink. As a result, it fails to serve the role of keeping the anode and cathode apart. Thus, we can say that the key is to make a thin but durable separator.

ㅣ If so, what makes SK Innovation’s separator different from others?

SK Innovation uses premium separators made by SK IE Technology (SKIET), its affiliated company. The gist of SK IE Technology’s separator technology lies in its sequential stretching and CCS coating.

First, sequential stretching is an independent technology first developed by SKIET in the world. It refers to a method of spreading out the separator material in a form of a highly viscous dough to be something like a thin film. The principle is to pull the dough once width-wise and then length-wise. Since the degree of stretching the base material in both directions can be flexibly adjusted, the thickness of the separator can be adjusted uniformly and precisely as desired. Sequential stretching is the very secret of SK IE Technology for outstripping Japanese counterparts that pioneered the separator market.

The second is Ceramic Coated Separator (CCS) coating technology. To put it plainly, it is a technology that applies a thin layer of fine ceramic stone powder on a separator. The CCS-coated separator becomes deformation-resistant. It prevents battery fires by well-withstanding external pressure and not shrinking even against heat.

SKIET has been supplying separators to major global battery manufacturers since 2007. The total area of the separator that has been sold reaches 2.2 billion m2. While being the top player in the global separator market, there has not been a single fire in the batteries that use the separators made by SKIET. That’s exactly why SKIET’s separators are popular among battery manufacturers.

The culmination of such technological prowess is SK Innovation’s key to securing safety while developing a high-output battery that can run 700 km on a single charge and can be charged within just 15 minutes. SK Innovation is also ahead of others in terms of the existing high nickel battery technology. SK Innovation’s world’s first NCM8 battery that increased the proportion of nickel to 80% was developed in 2016 and was mass-produced and supplied globally for the first time in 2018. The NCM9 battery that increased the proportion of nickel to 90%, was also developed for the first time in the world in 2019 by SK Innovation. This battery will be equipped in Ford’s first EV pick-up truck, the F-150 Lightning, next year.

ㅣ I’ve heard that SK Innovation has exceeded from battery cells to even develop a core technology to prevent a battery pack fire from occurring. What is it?

As I said, the causes of battery fires can be divided into the individual cell and battery pack perspectives.

With regards to a battery pack, the key to prevent a battery pack fire from happening depends on thermal propagation test. If we look into a battery pack, we will see an array of hundreds of battery cells. “Thermal propagation test” refers to whether or not it is possible to block heat from propagating to adjacent cells when a fire takes place in some cells in such an environment.

Concerning this matter, China assumed the minimum time required for passengers of an electric vehicle to escape is 5 minutes and set up a standard for keeping a fire from spreading to neighboring cells for 5 minutes. Nevertheless, if we cannot stop a thermal propagation itself, it will eventually end up with a fire, whether it be in 5 or 30 minutes.

SK Innovation holds an independent technological edge in terms of the thermal propagation test as well. The test of “E-pack,” solely developed by SK Innovation, proved that as it blocks heat from the source, preventing a fire from spreading. In fact, we’ve confirmed that an intentionally ignited fire in a battery cell in the middle of the battery pack was put out in around 30 minutes, while other battery cells are still working normally.

Usually, one may face a problem of lowered spatial efficiency, energy density, price rise, if they add other fire-proofing material in order to establish a thermal propagation test. The E-pack developed by SK Innovation is expected to further sharpen the competitive edge by space-saving and lowering prices with less number of parts used, while preventing heat from spreading.

▲ The three key technologies of SK Innovation’s EV batteries booth are introduced to visitors at InterBattery 2021

ㅣ Last question, what will dictate future batteries? And what is the direction of SK innovation’s next-generation battery?

In the future of the battery industry, I believe that “safety” will emerge as a more important issue rather than the shape/type of the batteries, whether they are pouch, prismatic, or cylindrical. Following technologies that increase energy density and fast charging performance, the future battery competition will ultimately focus on safety. Accordingly, SK innovation aims to lead the battery market in the future by adding new technologies related to thermal propagation test to the unrivaled safety technologies that we have already secured.

In addition, when it comes to next-generation batteries, SK Innovation is basically using an “Open Innovation” strategy. Through this, we continue to gather technology by collaborating with some of the world’s most technologically advanced companies and research institutes. We plan to determine which of these will be the best ones, and then use them as a base to develop our next-generation battery technology.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin