SK Geo Centric

SK Geo Centric

Through the previous post, we have introduced some basic definitions, the benefits and public sector’ plans to achieve a circular economy. It goes without saying, the private sector’s role is also highly important to “close the loop.”

In this episode, we will take a closer look at plastic waste – one of the most pressing environmental issues that the world is facing, followed by SK Global Chemical’s plans and actions to build a plastic circular economy. This post also features a part of a column written by Lee Jong-hyuk, one of the leaders of SK Global Chemical’s Green Business Group.

| Plastic waste – one of the most alarming environmental issues

In order to build a circular economy, we have to pay close attention to the most serious problems related to our daily habits: the use of plastics. Simply by taking a look around (wherever you are at the moment), you could see a lots of products and packages made from plastic material. The truth is there are even more plastic being used every day, but most of us do not notice it. With all of its strong features, plastic material itself is not something we can easily stop using, but how we should use it is much more important.

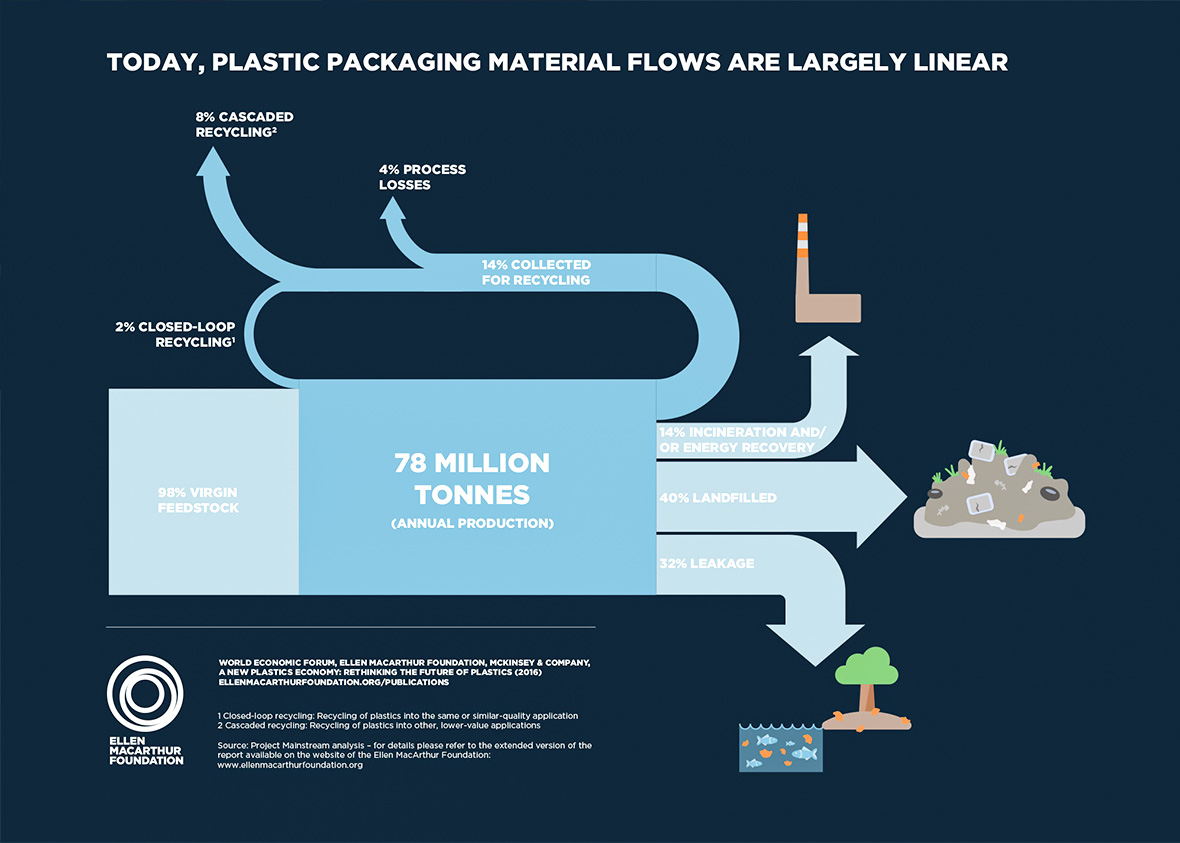

Based on a report named “The New Plastics Economy: Rethinking the future of plastics published” by Ellen MacArthur Foundation in 2016, most plastic packaging is used only once, and only 14% is collected for recycling.” The report also showed that every year, about USD 80 to 120 billion, which is the worth of 95% of the value of plastic packaging material, is lost to the economy.

The Foundation also stated, “We take oil and gas from the earth to make plastic products that are often designed to be used only once, and then we throw them away.” “This is what we call a linear take-make-waste model.”

Source: Ellen MacArthur Foundation

In short, the core problem of plastics is that we are using it in an unsustainable way. Hence, governments, corporations, and even consumers had made various efforts to reduce single-use plastic products. Ambitious goals had been set, but then the sudden hit of COVID-19 became a new obstacle.

Let’s take a simple example. In South Korea, in 2018, the Ministry of Environment made a policy that limited the use of single-use cups inside cafes, which means only take-out orders will be provided disposable cups and consumers were encouraged to use glass/porcelain mugs/cups or thermos. However, COVID-19 has stopped this policy as personal hygiene became the top concern.

According to Lee Jong-hyuk, “the COVID-19 crisis was a kind of trigger” of plastic waste problem. “From the masks that must be worn every day to the packages of delivery food and goods, as we all have to spend more time staying indoors, the world suffers more from plastic problems,” and “waste sorting and recycling sites have declared force majeure,” he explained.

Hence, along with the efforts of public sectors and consumers, the plastic waste problem has been pressing for more and more actions of corporates, another significant group in the establishment of a (plastic) circular economy.

| SK Global Chemical applies 3R strategy, taking part in building plastic circular economy

Being a petrochemical company that has plastic material as a major group of products, it is vital for SK Global Chemical to have strategies and action plans to ensure its sustainable growth.

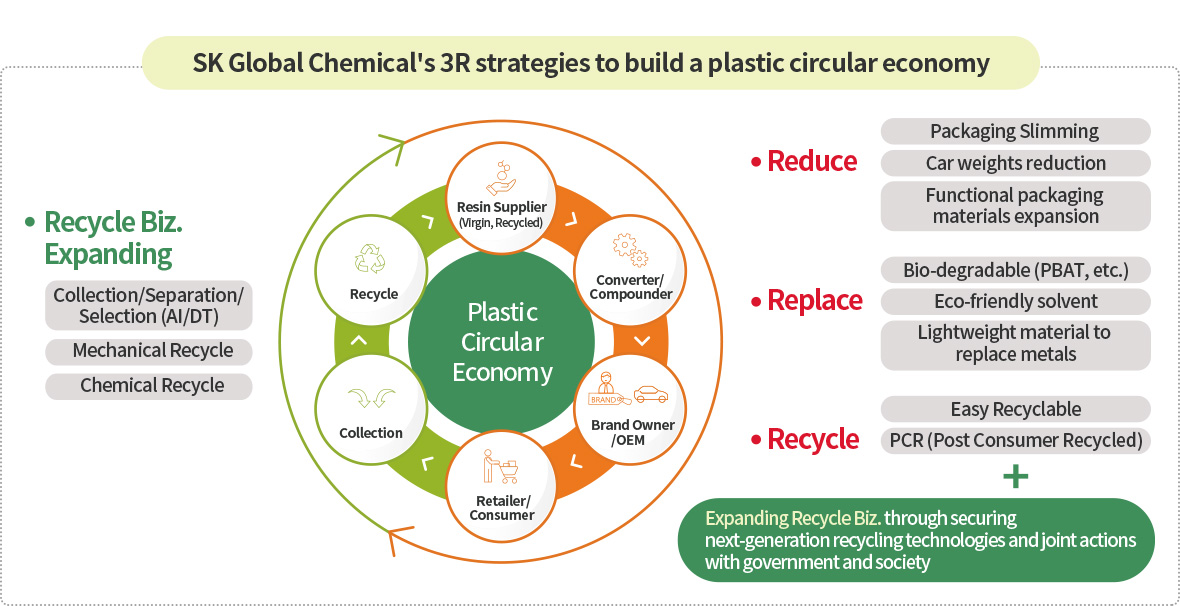

In 2019, CEO of SK Global Chemical Na Kyung-soo announced that the company had started actively implement 3R strategy, which includes Reduce, Replace, and Recycle. (Click here for more details regarding SK Global Chemical’s 3R strategy)

During the Circular Economy session at 2021 P4G Summit held last month in Seoul, CEO Na Kyung-soo also declared SK Global Chemical’s ambitious goal of “directly and indirectly contributing to recycling 100% or more of the plastic produced by the company.”

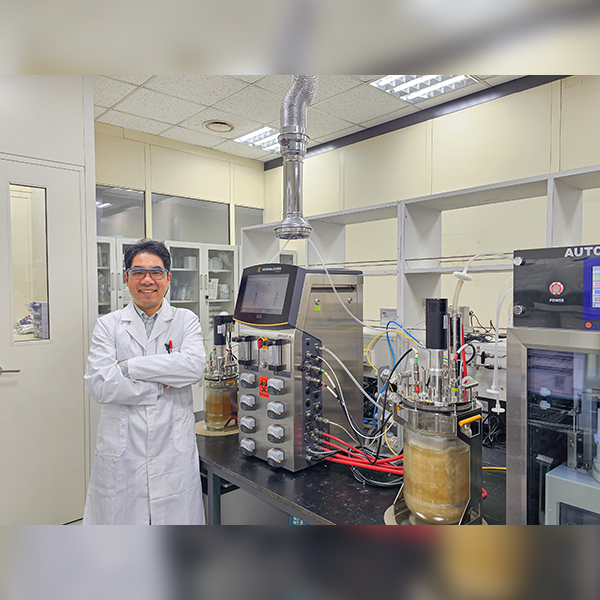

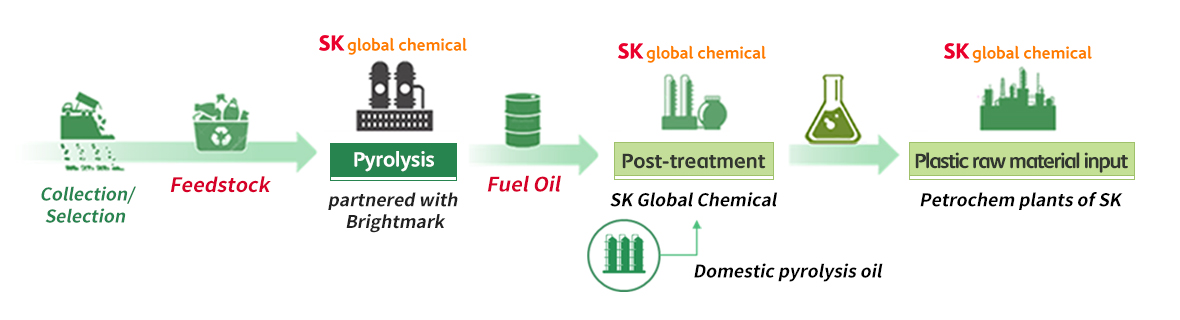

CEO Na Kyung-soo added that in order to increase the recycling rate, SK Global Chemical is focusing on chemical recycle. This is a technology that returns various plastic wastes such as waste PET, waste fiber, and waste vinyl back to petrochemical raw materials through pyrolysis technology. Lee jong Hyuk further explained, “Pyrolysis technology is a fundamental technology that changes the linear consumption structure of plastic into a circular structure by putting waste plastic/vinyl back into the production process.”

On the other hand, SK Global Chemical is also promoting mechanical recycle by applying its digital technology in plastic waste separation and gathering process, which are important processes in mechanical recycle technology.

Regarding its role in building a plastic circular economy, SK Global Chemical is making effort in becoming a chain connecter. Lee Jong-hyuk explained, “From the material production stage, we try to improve the materials so that it can be recycled more easily, while studying the properties of unrecyclable materials to find alternative ones. We also develop materials based on the demand of brand owners and the distribution industry. In the middle stage, we provide technology solutions needed by the converter.”

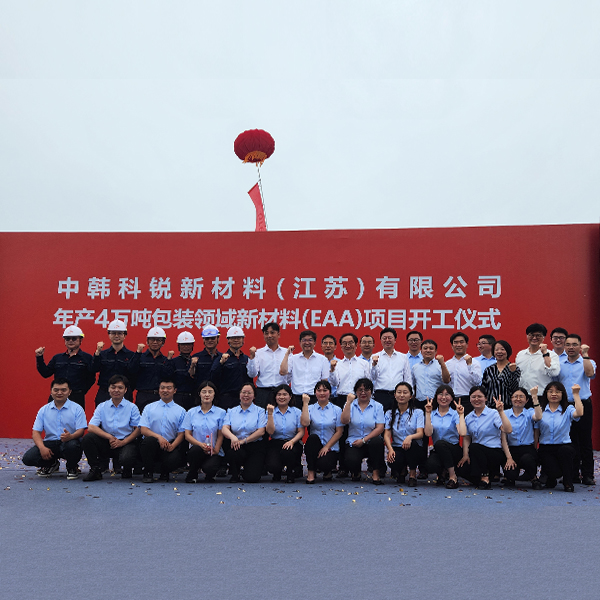

SK Global Chemical took preemptive action as a “chain connector” by hosting the Korea Eco-friendly Packaging Forum since 2019. This is a forum participated by various private, public, and academic institutions related to the packaging industry to discussion collaboration plans and solutions for the plastic waste problem. Since the beginning of this year, SK Global has signed MOUs with partners in various fields, operating a cooperative system in earnest. These partners include not only domestic but also overseas companies, such as Brightmark – a global waste solutions company that focuses on plastics renewal (plastic waste-to-fuel) and renewable natural gas (organic waste-to-fuel).

▲ CEO of SK Global Chemical Na Kyung-soo signed an MOU with CEO of Brightmark Bob Powell to aim for the first commercialization of waste plastic pyrolysis oil in Korea and investment in a plastics renewal facility

▲ Pyrolysis oil production process flow model suggested by SK Global Chemical, Birghtmark, and SK Incheon Petrochem

▲ (Left) SK Global Chemical and Kolon Industries show a sample of PBAT product jointly developed by the two companies and announced to launch it in Q3 this year / (Right) SK Global Chemical, Maeil Dairies, Tetra Pak Korea, Jushin Trading signed an MOU to promote aseptic cartons recycling in May 2021.

| It is hard but not impossible to close the loop

As the world is still struggling with the plastic waste problem, it is indeed a problem that can be solved instantly. It is also undeniable that even after being achieved, a circularity is always in jeopardy of being broken and going back to be linear. This is about not only plastic, but also all resources. Completing a circular economy of all resources requires the efforts of the whole society. It is necessary for the government to come up with stronger policies and clearer measures. Manufacturers, retailers, distributors have to try in the entire production/supply process as much as possible to deliver eco-friendly goods and services. Individuals have to pay more attention and change even small consumption patterns to become green consumers.

Through the leading examples introduced in our series, we hope you could have a better understanding about circular economy and support the efforts of public and private sectors, then move on to the next step: taking your own actions to contribute to building a circularity.

– CEO of SK Global Chemical proposes plan to recycle 100% plastic products at 2021 P4G Seoul Summit

– SK Global Chemical, Maeil Dairies, Tetra Pak Korea, Jushin Trading signed an MOU to promote aseptic cartons recycling

– Kolon Industries and SK Global Chemical to launch decomposing biodegradable plastic PBAT product in Q3 2021

– SK Global Chemical signed MOU with U.S. company Brightmark to solve waste plastic problem together

– SK Global Chemical held 2020 Korea Eco-friendly Packaging Forum

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin