SK On

SK On

As the share of the nickel in battery cathode materials for electric vehicles is expected more increasing, battery manufacturers are setting out to secure raw materials. In the meantime, SK Innovation is drawing attention for its recent moves.

SK Innovation announced that the company successfully signed a direct contract with a raw material provider in Australia on August 6. It seems that the company intended to gain a dominant position in securing raw materials resulting from the prospect that the supply of the nickel for batteries (Class-1 Ni) will be worsening after 2025 due to the rise in the demand for high-performance cathode materials.

According to the recent report by SNE Research (as of August 21), the cathode materials used in the batteries of global electric vehicles rose 80.9% to 112,000 t, compared with the same period of last year. In addition, NCM622 containing a higher nickel content ranked the 4th, and the cathode materials combining NCM811 and NCM424* ranked the 7th, both of which appeared in the top 10 for the first time. In contrast, NCM111 containing a lower nickel content recorded a drop of 34.8% in comparison with last year.

(*) NCM622, NCM811, NCM424 are batteries where nickel-cobalt-manganese are in the proportion of “6:2:2,” “8:1:1,” and “4:2:4,” respectively.

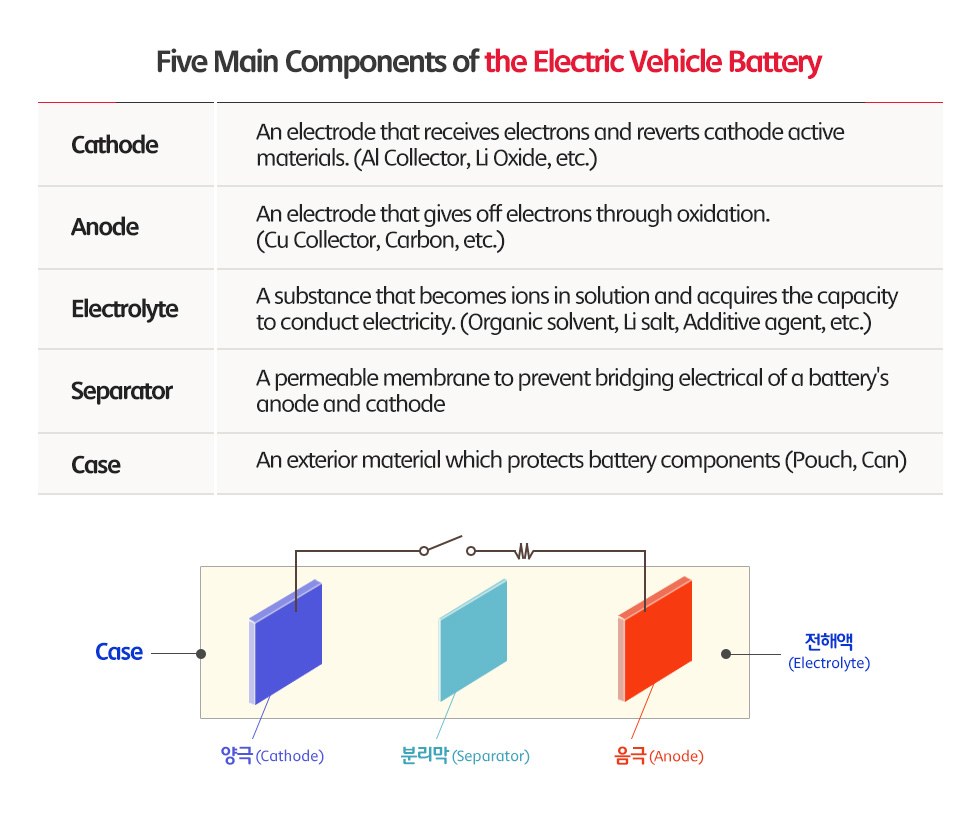

Batteries for electric vehicles usually use cathode active materials, such as nickel (N), cobalt (C), manganese (M) that have a low heating power, as cathode raw materials. Particularly, the increased nickel content that generates a higher capacity makes it possible to produce batteries with a higher energy density. Therefore, the stable increase of the nickel content in batteries is considered as a core technology to resolve the mileage issue per battery charge for electric vehicles.

Besides, battery manufacturers’ acceleration in high-density battery development influenced the prices of raw materials. The rapid growth of nickel demand caused the rise of nickel price. In last May, Adams Intelligence, a market research firm, analyzed the nickel used in the batteries of electric vehicles rose 57% compared with the previous year. Based on the London Metal Exchange (LME) price, nickel price increased more than 4 dollars in comparison with the beginning of the year, while the prices of lithium and cobalt dropped to the USD 30’s from the USD 90’s.

Grasping the market flow, SK Innovation took the fastest action by signing a purchase agreement with Australian Mines (AM), a mineral mining company in Australia, on August 6 to buy cobalt sulfate and nickel sulfate. The industry sees that SK Innovation secured the stable supply of nickel by deciding to buy 100% of proper minerals of nickel and cobalt being mined in Queensland, Australia.

SK Innovation decided to purchase raw materials based on the LME official price, not a fixed price, because the risk of battery price change can be minimized in a recent market situation where battery prices are linked with raw material prices.

The industry considers that SK innovation’s purchase of separately-processed nickel sulfate instead of metallic nickel makes it possible for the company to utilize them as a raw material for the production of cathode materials without any additional processing. The period of the contract is seven years, and a 6-year extension is negotiable depending on the market situation.

▲ SK innovation’s Electric Car Battery

Meanwhile, SK Innovation is the world’s first company that developed NCM622, having a highly-increased nickel share, in 2012, and successfully commercialized it in 2014. Furthermore, the company developed NCM811** in 2016 for the first time in the world and is soon to develop NCM9½½***, which has a mileage of 500 km per battery charge.

(**) NCM 811 is a battery where nickel-cobalt-manganese are in the proportion of “8:1:1.”

(***) NCM 9½½ is a battery where nickel-cobalt-manganese are in the proportion of “90%, 5%, 5%.”

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin