SK On

SK On

| SK Innovation started its EV battery business 38 years ago

Electric vehicle (EV) battery industry is emerging as the next leading business of Korea after the semiconductors business. Much like Korea’s other major industries such as electronics, vehicles, semiconductors and petrochemicals which achieved success after long preparation, the EV battery industry did not rise to the current growth path in a sudden.

SK Innovation’s dream of running a battery business started 38 years ago in 1982. It was the year when Korea Oil Corporation changed its name to Yukong after being acquired by Sunkyung Group. At that time, with the vision of becoming a “Total Energy Provider”, the company chose the “energy accumulation battery system” as a future businesses to start its journey.

Aiming to achieve its vision, Yukong established the Technology Support Laboratory, the predecessor of the current Institute of Technology Innovation in Daeduk, Daejeon, South Korea. The company began full-fledged preparations in the late 1980s and started developing high-tech EV batteries in 1991. In 1993, it successfully developed an EV capable of reaching 120km on a single charge, as well as the battery for it. Back then, EVs were regarded as something only found in sci-fi novels. In the early 2000s, SK Innovation has spurred its manufacturing batteries for hybrid EVs and pure EVs to keep up with the EV developments by many automakers. In 2010, the company also shared the moments that mark a turning point in the history of Korea’s EVs. Another big achievement of SK Innovation is that its battery was used in Hyundai BlueOn, the first mass-produced pure EV in Korea.

SK Innovation has also been a partner of various global top-tier automakers. Let’s look at the history of SK Innovation’s EV battery, which has almost reached the 40th year, and the memories of its earlier days to find out why it has captivated the hearts of many global automakers.

| Early stage of SK Innovation’s batteries

01 | Energy accumulation battery system, Yukong’s new future

▲ From Sunkyung’s 40-year History Book – “Yukong Managers Meeting

with former Chairman Choi Jong-hyun” held on December 9, 1982

SK Innovation’s battery dream is well-manifested in “Sunkyung’s 40-year History Book,” which was published in 1993. Early ambitions can be felt in the image of the Yukong Managers Meeting with former Chairman Choi Jong-hyun held on December 9, 1982.

According to Sunkyung’s 40-year History Book, former Chairman (President then) Choi Jong-hyun set up a president room in Yukong in 1981 to devote himself to improving the company’s management based on “SKMS (SK Management System).” On December 9, 1982, he announced a proposal on the company’s new future during the meeting with the other mangers.

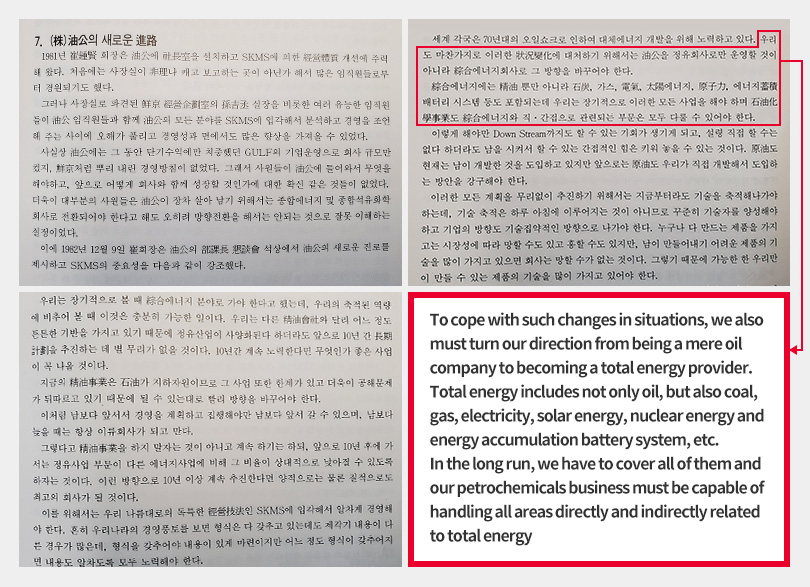

“After the oil shock of 1970s, many countries around the world are trying to develop alternative energy sources. To cope with such changes in situations, we also must turn our direction from being a mere oil company to becoming a Total Energy Provider.

Total energy includes not only oil but also coal, gas, electricity, solar energy, nuclear energy

and energy accumulation battery system, etc. In the long run, we have to cover all of them

and our petrochemicals business must be capable of handling all areas directly and indirectly

related to total energy.

That is the only way to earn opportunities for downstream operations, and even if we cannot do so directly we can build up the indirect power by ordering the others to make it.

Even though we are acquiring the crude oil developed by others, in the future, we need to devise a plan to develop and acquire it all by ourselves.

To proceed with all these plans at ease, we must accumulate technologies from now on. But technology accumulation does not happen overnight,

so we have to continue to foster technicians and keep the company moving in a technology-intensive direction. A business may thrive or die depending on the marketability if the products can be made by many others, so we must have the technologies to make products that are difficult to be made by the others.

At the same event, Chairman Choi also explained Yukong’s vision of becoming a Total Energy Provider by saying “We must change our directions as soon as possible, because the oil refining business has unavoidable limitations as oil is an underground resource, and there are also concerns about pollution. I am not saying that we should not do the refining business, but its size must be kept smaller than our other energy businesses in the next 10 years.”

02 | Yukong established the first Technical Support Research Laboratory of Korean oil refinery industry

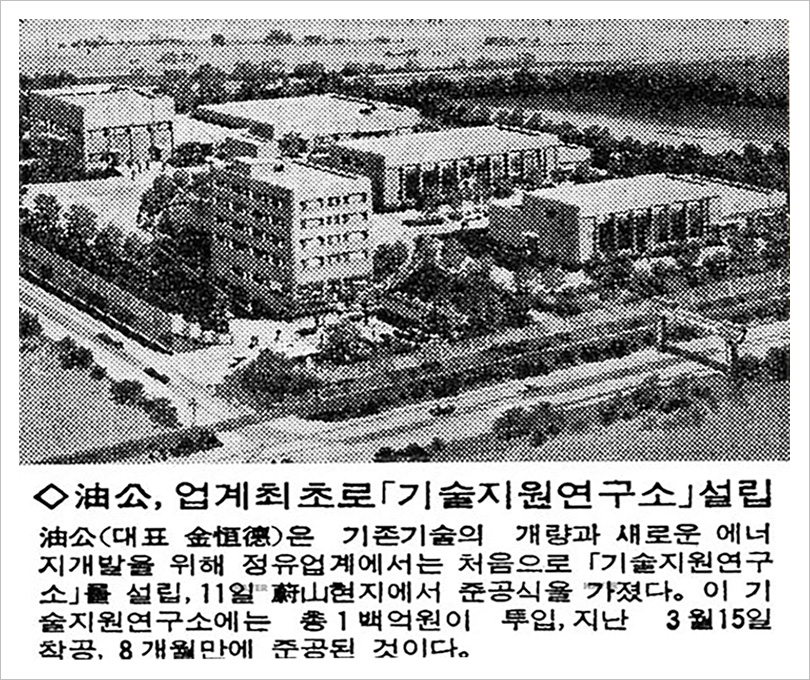

▲ Newspaper coverage, on November 12, 1985, of the Korean Oil Refinery industry’s first technical support laboratory established by Yukong (captured from News Library)

A newspaper reported on November 12, 1985, Yukong established the first Technology Support Research Laboratory of Korean oil refinery industry to enhance existing industrial technologies and to develop a new energy source. The ceremony for completion of the research laboratory was held on November 11, 1985 in Ulsan. With 10 billion KRW invested, construction of the research laboratory started from March 15, 1985 and it was completed in 8 months.

03 | Yukong announced its plan to develop four-wheel EVs using high-tech storage battery (EV battery) in December, 1991

▲ Newspaper coverage of Yukong’s plan to develop high-tech storage batteries published on December 23, 1991 (Captured from News Library).

The news that Yukong set to develop electric vehicles was found on an article published on December 23, 1991. The article stated that Yukong successfully manufactured and tested a three-wheel electric vehicle using solar cells in its petroleum research lab in Ulsan, South Korea. Following the manufacturing, the company decided to manufacture a four-wheel electric vehicle by the first half of 1992.

According to the article, Yukong “came up with a plan to develop storage batteries which are key component of electric vehicles, and aim to complete the development by the end of 1993. The three-wheel electric vehicle manufactured as a pilot product has maximum speed of 20km per hour and is capable of about 40km of driving before it needs to be recharged. Following its pilot product, development of a four-wheel electric vehicle using storage batteries will begin in 1992, and by July the driving test is planned to take place. This development of electric vehicles is part of Yukong’s research efforts on development of high-tech storage batteries.” The articles also added that Yukong “plan to develop storage batteries that are lightweight and have high energy intensity. So the batteries to be used could be nickel-cadmium batteries, nickel metal hydride batteries, or sodium-sulfur batteries.” In addition, it was also written in the article that Yukong “will invest 1 billion KRW in R&D of four-wheel electric vehicles and another 500 million KRW in the development of storage batteries.”

04 | Yukong’s Ulsan Research Laboratory was selected as the Development Supervision Institution of high-tech storage batteries for EVs

▲ The 6th Yukong Newsletter issued in December, 1992 featured a news report entitled “Yukong’s Ulsan Research Laboratory was selected as the Development Supervision Institution of high-tech storage batteries”

The 6th Yukong Newsletter issued in December, 1992 showed that the company’s Ulsan Research Laboratory was selected as as the Development Supervision Institution of high-tech storage batteries for EVs, which was one of the G7 science and technology projects*. Other partners of the project included Kia Motors, a research lab for automotive parts, a research lab for mechanics, and Yonsei University. The newsletter explained that these organizations would receive government support to develop sodium-sulfur batteries as high-tech storage batteries for electric vehicles by 1998. Yukong was designated as the leading developer in the project because it was the only company that was conducting research on batteries back then.

The report said, “New Energy Research Team of Ulsan Research Laboratory will be funded 1 billion KRW from the government for the project by 1995 by which the phase 1 of the research will be completed. The sodium-sulfur batteries the center will develop are the best storage batteries. When installed on electric vehicles, the batteries will enable an electric vehicle to run three times longer driving mileage (about 300km) at one charge than conventional batteries.”

The report also went on to explain that in 1992, only 4 companies in the world – HBS in Canada, HBB in Germany, Chloride in the UK, and NDK in Japan – had the world-class battery technologies.

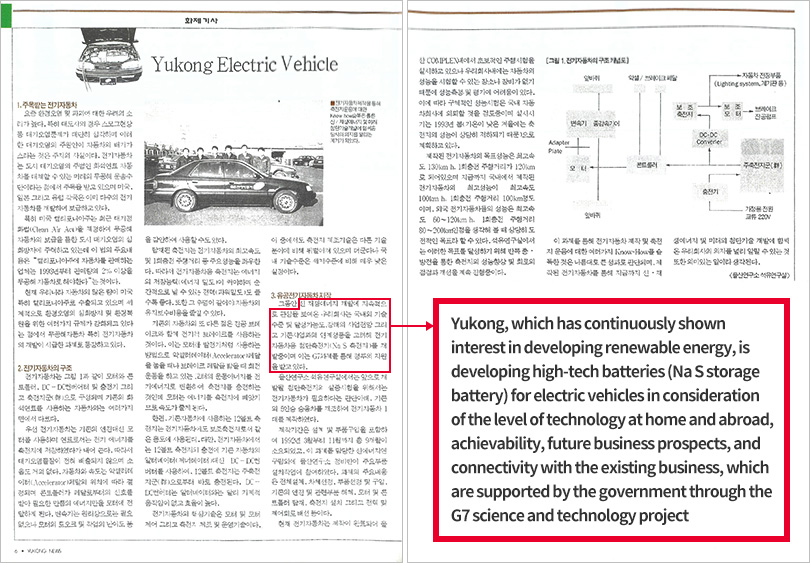

05 | “Yukong News” published in January 1993 with a feature article on Yukong’s electric vehicles

▲ A feature article related to Yukong’s electric vehicle, published in the “Yukong News Release 86” in January 1993

Yukong News Release 86, which was published in January 1993, introduced a feature article on EVs in details on two pages. The article explained the background and the structure of an electric vehicle, disclosing to the public that Yukong was developing an electric vehicle.

The article revealed, “Yukong, which has continuously shown interest in developing renewable energy, is developing high-tech batteries for electric vehicles in consideration of the level of technology at home and abroad, achievability, future business prospects, and connectivity with the existing business, which are supported by the government through the G7 science and technology project.”

The article also said, “The petroleum laboratory of the Ulsan Research Laboratory made one electric car by remodeling the existing five-seater sedan under the judgment that the electric vehicle is required for the demonstration test of the advanced storage battery that will be developed in the future,” and “It took a total of 9 months to produce from March to November 1992, including design and parts purchase. In addition to the new energy research team in charge of this task, the maintenance team of the Ulsan Research Laboratory participated in the installation of major parts. The Petroleum Lab is continuing to improve the performance of the storage battery and check and improve the circuit through repeated charging and discharging.”

The end of the article emphasized “It would be a great achievement to acquire various know-how in electric vehicle manufacturing and battery operation through this project, and also meaningful to publicize Yukong’s commitment to developing new and renewable energy and future high-tech technologies through electric vehicles.”

06 | Yukong developed an electric vehicle in January 1993

▲ An article on the development of Yukong’s electric vehicles reported in a newspaper on January 19, 1993 (captured from News Library)

On January 19, 1993, a newspaper reported that Yukong developed an electric vehicle. The article revealed, “Yukong made a test electric vehicle for the practical use of high-tech storage batteries for electric vehicles and started a driving test. The existing five-seater vehicle, modified by Yukong’s own engineers and equipped with motors and controller accumulators, is currently being tested for driving at the Ulsan Petrochemical Complex.”

The article continued, “Yukong’s electric car for demonstration test of high-tech batteries has a maximum speed of 130 km/h, a driving distance of 120 km on a single charge,” and “In the meantime, the best performance of the domestically developed electric car is 100km/h at maximum speed, 100km at a single charge, and the foreign electric car has a maximum speed of 60km/h to 120km/h, and reach 80km to 200km on a single charge,” showing expectation that “If the performance of Yukong’s electric car is proven, it will speed up the commercialization of domestic electric vehicles.”

| The present and future of SK Innovation’s Battery Business

Such a long history of batteries has made SK Innovation today. In 2012, SK Innovation developed the world’s first battery with NCM622 cathode materials mixed with a nickel-cobalt-manganese ratio of 60%, 20%, and 20%, respectively, and succeeded in mass production in 2014 for the first time in the world. SK Innovation has also developed the world’s first battery with NCM811 cathode material in 2016 and has been mass-producing it since 2018. Moreover, the company succeeded in developing the world’s first battery with NCM9 1/2-1/2 cathode and is currently planning to mass-produce it in 2022 in line with demands from OEMs.

Furthermore, the company is making aggressive investments in the U.S., China, and Europe to become a global top tier beyond Korea. Accordingly, SK Innovation’s production volume of electric vehicle batteries will be expanded to 20GWh in 2020, 71GWh in 2023, and 100GWh in 2025.

In the meantime, SK Innovation aims to grow into an e-mobility solution provider by establishing a BaaS (Battery as a Service) system with 5R (Rental, Recharge, Repair, Reuse, Recycle) as a strategic platform that can complete not only production of EV batteries based on e-mobility but also the front-to-back value chain of the battery business.

SK Innovation’s dream of becoming a Total Energy Solution Provider, which started about 40 years ago in 1982, is now underway.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin