Trends & Reports

Trends & Reports

Have you ever wondered how crude oil is delivered to many parts of a country in enormous quantities, after being shipped by oil tankers across the oceans? Some might think that it is transported like ordinary cargo, loaded onto large trucks or trains. However, in fact, there is a special method of transportation solely dedicated to carrying oil. Let’s find out what it is.

On May 28, 1879, a revolution in oil transportation began. Crude oil, which had been carried only in barrels (i.e., a container made by weaving together pieces of wood), started being transported through oil pipelines. An impressive amount of approximately 2 million liters of oil, which would have required around 12,500 barrels, flowed through these pipelines at once. Thus, the history of oil pipelines, traversing steep mountains and vast lands, began.

▲ An Allied oil tanker torpedoed and sunk in Atlantic Ocean by German submarine in 1942 (Source: Wikipedia)

During the 4 years of World War I from 1914 to 1918, as fuels for automobiles and aircraft were essential, crude oil became more significant than ever. Later, after the end of World War II, which was also called “the first oil war,” pipelines started becoming the primary means of oil transportation. At that time, the U.S. transported war supplies and oil using cargo ships and tankers. However, many ships and goods sank to the bottom of the ocean from torpedo attacks by German submarines that were patrolling the Atlantic coast. The giant oil tankers were especially more visible and slower than other cargo ships, making them the main targets for German submarines. As a result, not only was the supply of oil needed by the Allies disrupted, but the supply of oil intended for use in the eastern regions also was jeopardized.

▲ The construction of the Big Inch pipeline recorded by John Vachon (Source: Wikipedia)

The U.S. government came up with an idea to resolve the oil transportation issues. It was to build a long-distance “oil pipeline” that could carry crude oil produced in Texas to the refining facilities concentrated in the East. On August 14, 1943, just a year after the construction began, the U.S. completed an oil pipeline from Texas to New Jersey that stretched 2,018 kilometers and crossed over 8 states and 20 rivers. The pipeline had a diameter of 24 inches, which was five times larger than what had been used previously, hence the name Big Inch. This Big Inch pipeline could transport 300,000 barrels of crude oil per day, enabling efficient and safe oil transport during the war.

A year later, the Little Big Inch was completed. It was a pipeline with a reduced diameter of 20 inches extending over a total of 2,373 kilometers, surpassing the length of the Big Inch and further increasing efficiency. The Big Inch and Little Big Inch pipelines played a critical role in transporting more than half of the oil within the U.S., ultimately contributing to the victory of the Allies in World War II.

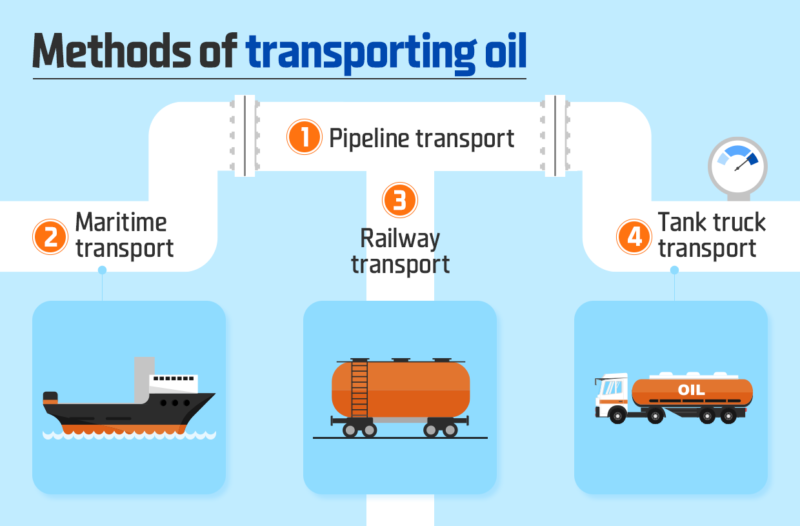

According to the Deahan Oil Pipeline Corporation (hereinafter, DOPCO), pipeline is a safer and more economical means of transportation compared to maritime, railway, and ship. They help alleviate traffic congestion and reduce logistics costs and the storage effects of petroleum products. The beginning of South Korea’s oil pipeline history dates back to 1969 when the U.S. 8th Army constructed the Trans-Korea Pipeline (TKP, 452 km) connecting Pohang to Uijeongbu. Following this, in 1971, SK Innovation’s predecessor, Yukong, constructed an oil pipeline (YKP, 101 km) for transporting its products between Ulsan and Daegu, which was also connected to the Trans-Korea Oil Pipeline.

Currently, South Korea has an extensive network of oil pipelines managed by DOPCO, divided into six major lines, which the government and oil refineries, including SK Energy, jointly established. Along these pipeline routes are various SK Energy logistics centers and DOPCO storage depots. The pipelines connect the SK Innovation Ulsan Complex (Ulsan CLX) and SK Incheon Petrochem to inland urban areas such as Seoul, Daejeon, Daegu, Gwangju, and Jeonju.

▲ Panoramic view of SK Innovation Ulsan Complex

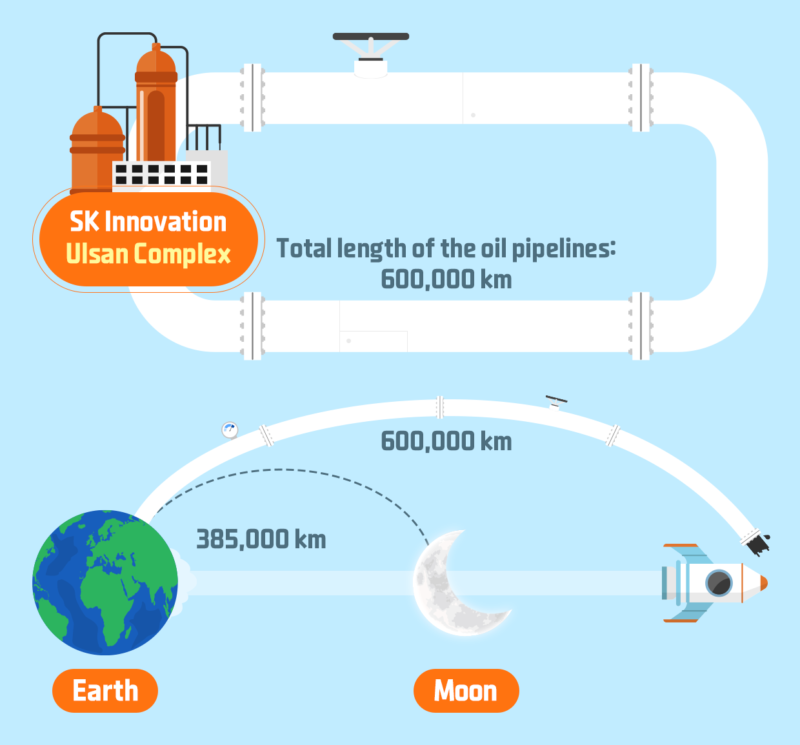

Oil pipelines are more stable and less susceptible to external factors such as weather and traffic conditions compared to other transportation methods, making them responsible for the largest portion of primary light oil transportation within South Korea. In fact, about 30% of the light oil products like gasoline, diesel, kerosene, and aviation fuel shipped from Ulsan CLX are transported via pipelines. The total length of the pipelines within the Ulsan CLX plant is 600,000 km, which exceeds the distance between the Earth and the Moon (approximately 385,000 km).

In addition to transporting, the oil pipeline network handles all processes, from refining crude oil to providing petroleum products. The journey of the pipeline from the oil field to the refinery and from there to the final consumption points is divided into three main stages.

1. Gathering System

The term refers to the pipeline and accompanying facilities that transport crude oil from an oil well located within an oil field to a designated location. This system is interconnected with various branch lines to move the crude oil, with the diameter of the pipes typically ranging from 10 to 30 cm. Generally, these pipelines serve to collect crude oil produced in oil fields, resulting in shorter pipelines compared to other systems.

2. Trunk Line System

This system transports crude oil from oil fields to receiving points such as refineries and requires extensive construction as it is the longest of the three-stage system. Consequently, construction methods, pipe material improvements, and design techniques have continuously evolved to accommodate the extensive lengths required for these pipelines.

3. Distribution System

This system transports petroleum products from product supply locations such as refineries and ports to the final consumption sites. It extends into regional interiors and consists of smaller branch lines. The distribution system transports products like gasoline, kerosene, and aviation fuel. As it transports various petroleum products, it is crucial to accurately classify the quality and grade of such products and detect minute changes in the oil ratio. Consequently, the development of oil ratio detection devices and oil flow prevention mechanisms in the system has advanced.

![]()

Petroleum, originating from deep beneath the earth, is utilized in various aspects of our daily lives. The reason petroleum can be a part of our daily lives is primarily thanks to the oil pipelines that transport oil across different regions of the world.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin