2025.01.17

Trends & Reports

Trends & Reports

When we feel exhausted by the scorching heat of summer or have a fever from severe cold, we often cool ourselves down by wiping our bodies with towels soaked in cold water. This is because as the water evaporates into the air (evaporative cooling), the heat from our bodies also decreases, similar to how sweating works. Contrarily, in polar regions, spraying water on the walls of an igloo (which is made of snow bricks) makes the temperature of the liquid water decrease and turns into solid ice. During this process, the heat in the water is released inside, warming the igloo. Similarly, when people say, “It becomes warm when it snows,” it is not just a feeling but a scientific-based principle. When the water vapor deposits into snow, it releases heat energy.

The above example shows that although a substance has the same consistent properties, its use can differ greatly depending on situations or conditions, just like a chameleon does. It may seem ironic at first, but this explains why refrigerants, which literally means a chemical substance to make or keep things cold, are also used in the heating system of electric vehicles (EVs). Let’s examine the principle more closely.

❄️ What is refrigerant?

Air conditioners produce cool wind, and refrigerators store food safely. This is all made possible by a special medium, the refrigerant. Refrigerants absorb heat from their surroundings or high-temperature substances, reducing the temperature. They are often used in cooling devices to make air cool and fresh.

The principle of refrigerants can be found easily in our daily lives. For example, on a hot summer day, when you spray water on the ground or road, the water absorbs heat as it evaporates, creating a cooling effect. Similarly, the ice packs used in delivering meat or seafood use the same principle. The engine coolant used as a heat source for the heater in internal combustion engine (ICE) vehicles is also a type of refrigerant that takes away engine heat and discharges it outside. In essence, a refrigerant is a substance for transferring heat.

What is interesting is, as mentioned earlier, the refrigerants used in EVs are not only used for cooling but also for heating. So how is this possible?

❄️ The evolution of refrigerants for environment and efficiency

Refrigerants are categorized into natural refrigerants and synthetic refrigerants. Ammonia (NH3), hydrocarbons (HCs), and carbon dioxide (CO₂) are common examples of natural refrigerants. Natural refrigerants are substances that exist in their natural state, thus having a minimal impact on the environment. However, they are characterized by low efficiency, and most have issues with toxicity and flammability, which can pose potential harm in case of leakage

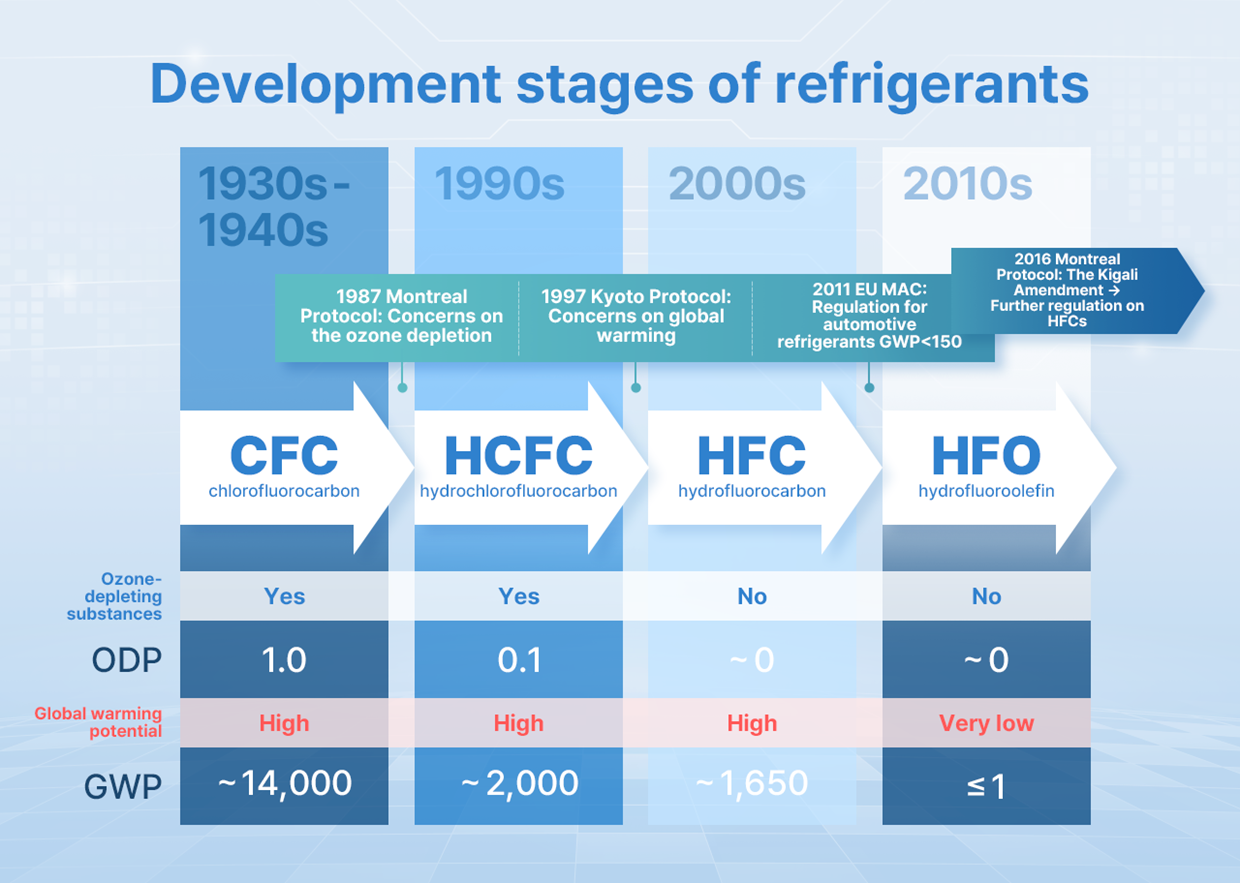

Synthetic refrigerants were developed to overcome those issues the natural ones. In the 1930s, the first generation of synthetic refrigerants was developed. Chlorofluorocarbon (CFCs) series organic compounds were harmless to humans and not easily flammable. These refrigerants were widely used for a long time due to their high stability. However, by the late 1980s, it became known that CFCs were severely depleting the ozone layer in the atmosphere. As a result, the United Nations (UN) banned and regulated substances through the Montreal Protocol*.

(*) Montreal Protocol: Officially known as the “Montreal Protocol on Substances that Deplete the Ozone Layer” It aims to minimize the damage to humans, animals, and plants caused by ozone layer depletion through the prohibition and regulation of substances that destroy the ozone layer, such as chlorofluorocarbons or Freon gas, and halons. It was adopted in September 1987 and came into effect in 1989. South Korea joined the protocol in February 1992, and it was enacted in May.

In a continuous global effort to reduce the environmental destruction caused by refrigerants, the fourth-generation Hydrofluoroolefins (HFOs) are currently replacing previous-generation refrigerants. The representative fourth-generation refrigerant R-1234yf, developed by global chemical giants, has an ozone depletion potential of 0 and a global warming potential of 4. This is widely utilized as it has the least impact on climate change among the synthetic refrigerants that have been developed so far. However, HFOs are more expensive and flammable compared to previous refrigerants.

The major substance of fourth-generation refrigerants is hydrofluoroolefin (HFO). HFO is made of perfluoroalkyl and polyfluoroalkyl substances (PFAS). PFAS possess exceptional properties, such as water resistance, heat resistance, and corrosion resistance. They have been used for decades as raw materials or coating agents for automotive refrigerants, vehicle batteries, and electronic components. Especially they played a role in preventing corrosion in automotive refrigerants and enhancing durability for long-term use.

However, as the negative impact of PFAS on the environment and human body was disclosed, the European Union (EU) announced a policy to broadly restrict PFAS. From 2026, restriction on the use of PFAS is expected. The US is also classifying PFAS as a toxic substance and is currently strengthening regulations. Therefore, the development of new-generation refrigerants that can surpass the fourth-generation synthetic refrigerants in terms of safety is required.

❄️ Differences between automotive refrigerants and general refrigerants

Refrigerants are used in various places. The application of general refrigerants varies depending on the use environment, purpose, materials used in the HVAC systems, size of the pipes, refrigerant capacity, and targeted performance. For example, refrigeration warehouses and refrigerators use larger quantities of refrigerants than cars, and the target temperatures are lower.

Automotive refrigerants have mainly utilized third-generation HFC-based substances. However, due to the strengthened regulation regarding their high GWP, as previously mentioned, the development of automotive refrigerants has progressed rapidly to overcome these issues compared to general refrigerants.

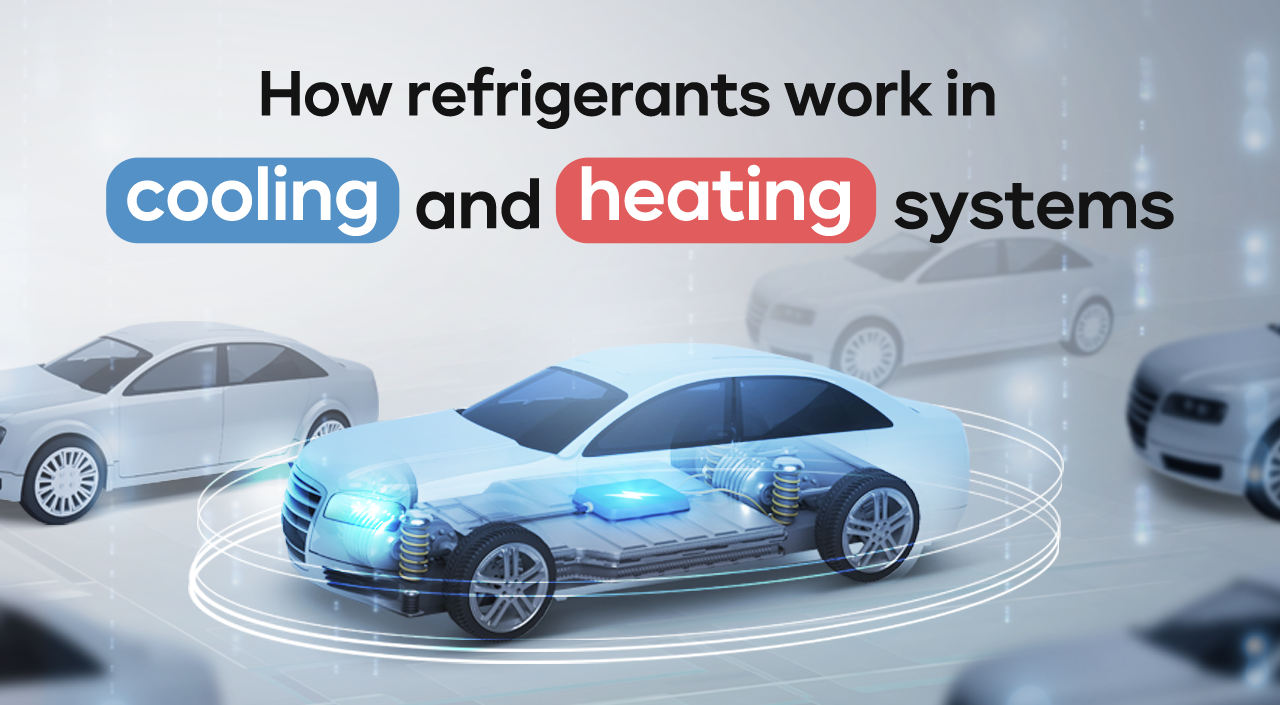

While internal combustion engine (ICE) vehicles can use the engine’s waste heat to heat the vehicle, EVs use batteries that do not generate much heat. Therefore, EVs need another heating method which utilizes the automotive HVAC system. EVs require more efficient and environmentally friendly refrigerants compared to the existing ones. There is ongoing research and development to meet these requirements.

❄️ What is automotive HVAC?

Automotive HVAC (Heating, Ventilating, and Air Conditioning) is a system that mixes air produced by the air conditioning and the heater and then supplies it inside the car. In the case of EVs, the HVAC system is integrated into a thermal management system that comprehensively controls the temperature of all the vehicle’s components, including the batteries.

The functionality of the HVAC system, as perceived by the passengers, is not related to the vehicle’s power source, which defines whether a vehicle is an ICE one or an EV, but the technology employed to achieve this functionality differs.

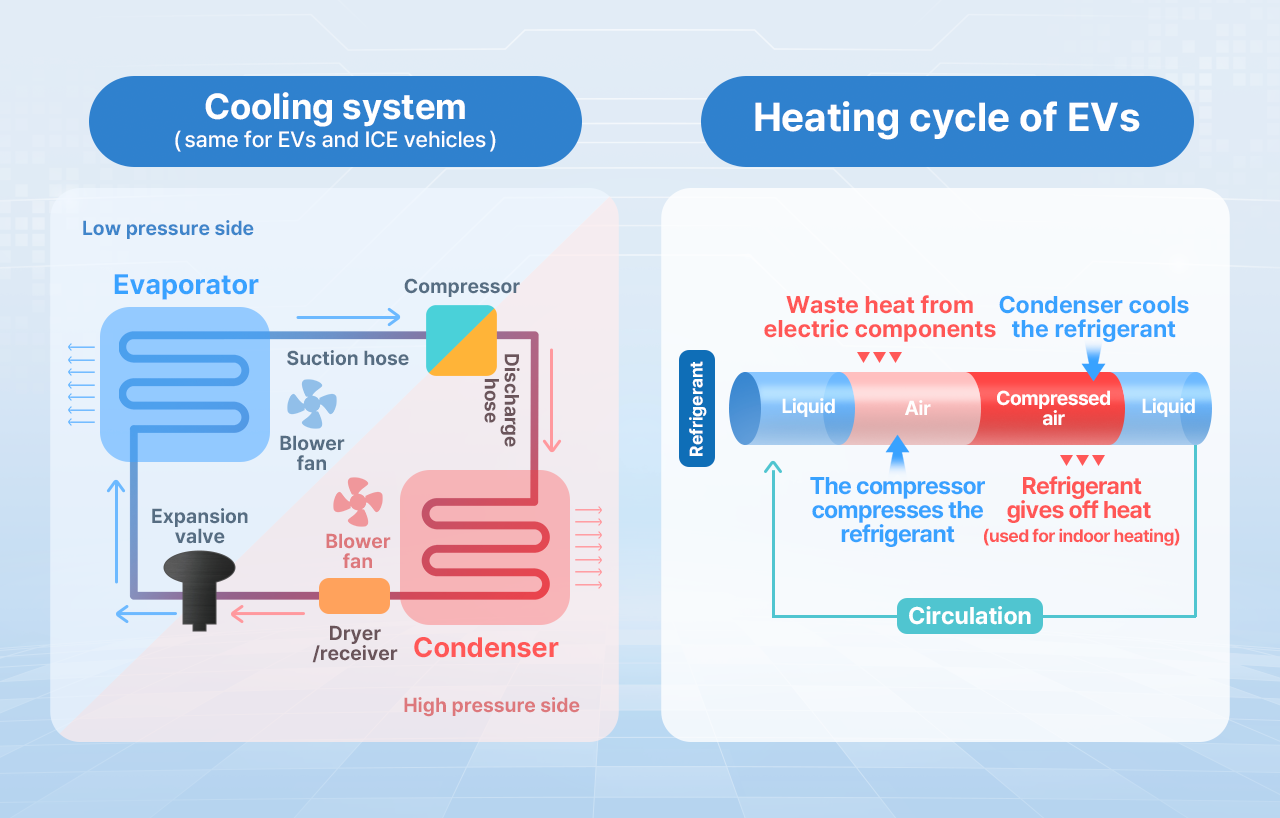

When taking a look at the air conditioning system first, both ICE vehicles and EVs have a similar structure. Similar to a household air conditioner, it works by circulating a refrigerant that absorbs heat from inside, cools it down, and then releases the absorbed heat outside the vehicle. This process is repeated. However, the difference is in how the compressor, needed for the circulation of the refrigerant, is powered. In ICE vehicles, it’s connected to the engine, while in EVs, it operates on an electric motor for the HVAC system.

The biggest difference is the heater. As briefly explained earlier, the heater in ICE vehicles utilizes the engine’s heat for heating, allowing it to continuously supply warm air inside as long as the engine is running. On the other hand, EVs, which lack an engine, require a separate heat generation device. In other words, the operation of the heater heavily relies on the electrical energy charged in the vehicle to generate the necessary heat. Therefore, the efficiency of the HVAC system in EVs is a crucial factor directly linked to the vehicle’s driving range.

❄️ Differences between PTC heaters and heat pumps

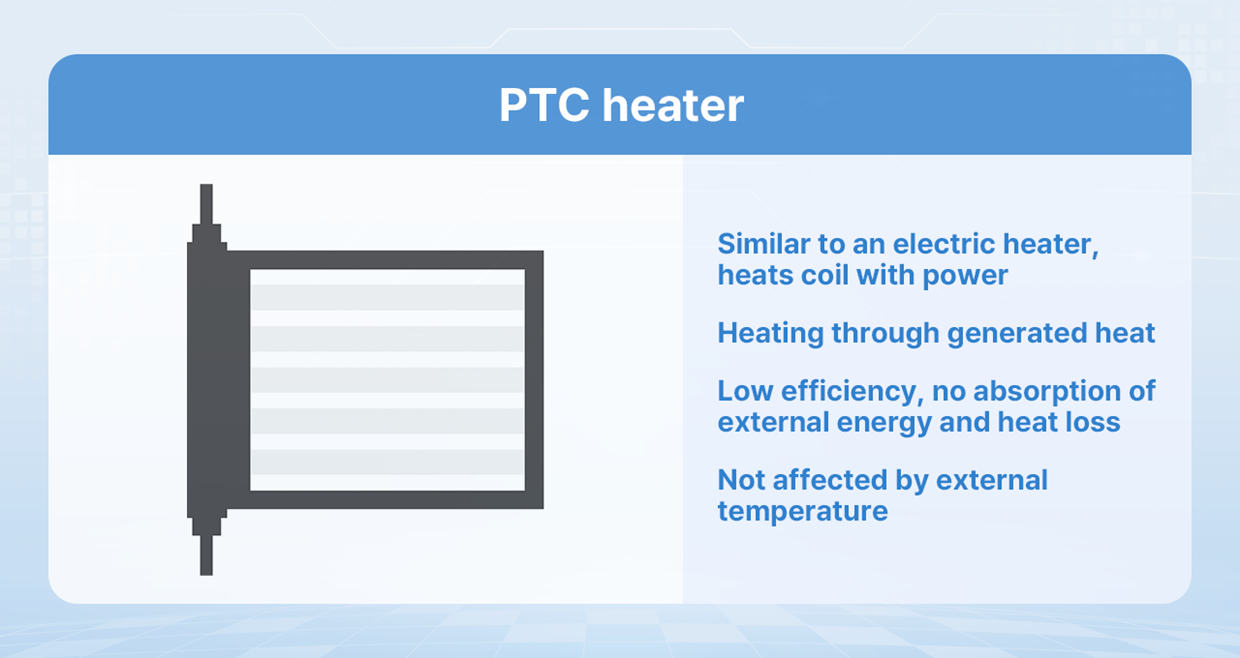

The sources of heat for EV heaters are primarily divided into PTC (Positive Temperature Coefficient) heaters and heat pumps. The PTC heaters convert electrical energy directly into heat energy, but they have the disadvantage of low efficiency.

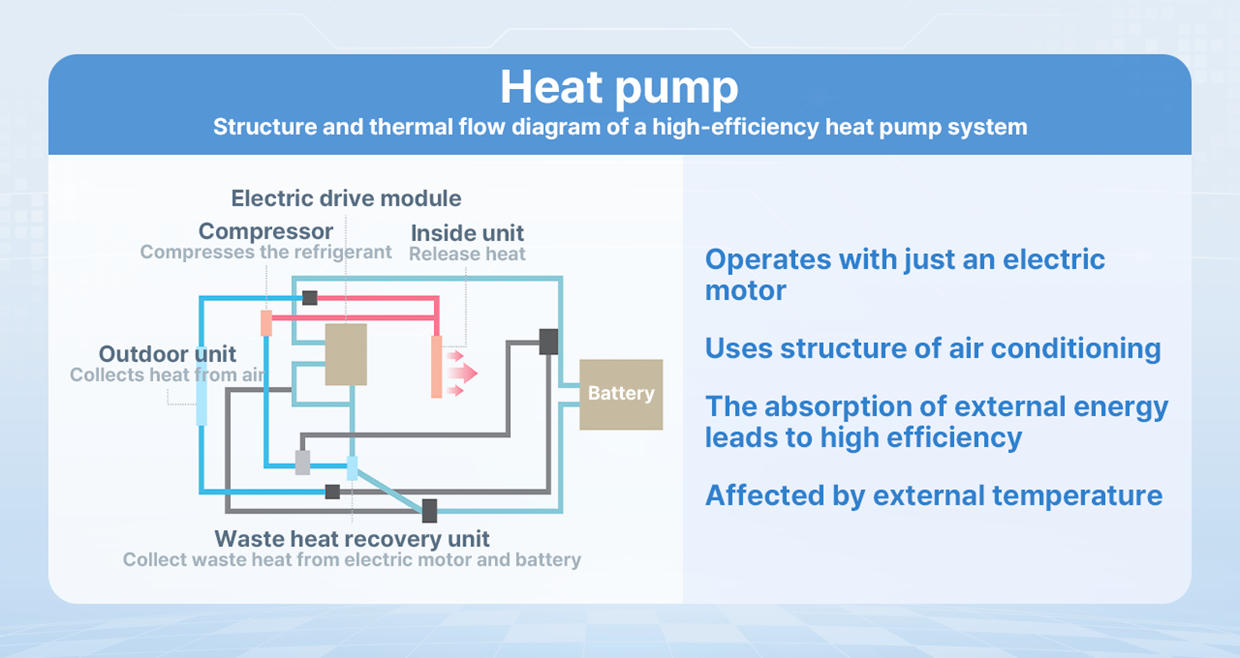

Heat pumps, on the other hand, operate on the same principle as air conditioners but in reverse. It is easier to understand by imagining that the roles of the indoor unit, which emits cool air in household air conditioners, and the outdoor unit, which emits warm air, are swapped.

Heat pumps operate with just an electric motor to circulate the refrigerant, similar to air conditioners. By adding some components, the structure of an air conditioner can be utilized as is, making it more efficient than PTC heaters. Furthermore, integrating heat pumps with air conditioners can reduce the size and weight of the HVAC system, and this can lead to decreased energy consumption and increased driving range.

However, simply integrating air conditioners and heat pumps has its limits in improving the efficiency of the HVAC system. Since the refrigerant used in conventional air conditioners excels in cooling performance but lacks in heating performance, the development of next-generation refrigerants that satisfy both performances is necessary. In January this year, SK Innovation’s subsidiary SK Enmove and Hyundai Motor Group signed a memorandum of understanding (MOU) to develop next-generation refrigerants for vehicles, which was a move that reflected environmental changes and market trends.

❄️ HVAC Fluids, the next-generation refrigerants introduced by SK Enmove

Adapting to increasingly strict regulations for our sustainable future is both our duty and an unavoidable reality today. The refrigerant market is no exception. It is imperative for national industries and corporations to develop next-generation refrigerants to maintain global competitiveness.

CEO of SK Enmove Kim Wone-kee (left) and President of Hyundai Motor Company Yang Hee-won (right) are taking a commemorative photo after signing the MOU for the development of next-generation refrigerants at SK Seorin Building in Jongno, Seoul on January 25.

In line with this grave situation, SK Enmove and Hyundai Motor Group announced on January 25 that they have signed a “Memorandum of Understanding (MOU) for the Development of Next-Generation Refrigerants.” Through this business agreement, SK Enmove is responsible for developing next-generation refrigerants, while Hyundai Motor Group will develop the vehicle thermal management system that incorporates these refrigerants.

The next-generation refrigerant, “HVAC Fluid,” currently under development by SK Enmove, is designed to comply with PFAS regulations. This product, which enhances the heating performance of existing vehicle refrigerants, can increase the EV’s driving range by improving its energy efficiency during the winter season.

HVAC Fluid consists of substances such as refrigerants, which are responsible for heat transport in the HVAC system, and refrigeration oil. Refrigeration oil is crucial not only for its lubrication performance, including friction, wear, and reduction capabilities but also for its compatibility with the refrigerant. This is due to the fact that the refrigerant oil plays a crucial role in the process where the compressor within the refrigeration system intakes and compresses the refrigerant, which is the working fluid, ensuring that the refrigerant is properly mixed and circulated within the system. Moreover, the refrigerant oil’s high compatibility with the refrigerant enhances the system’s stability.

According to external research institutions, the refrigerant developed by the two companies is expected to improve heating performance by more than 30% compared to existing refrigerants. Additionally, both companies plan to develop this vehicle refrigerant for use in ICE vehicles as well.

SK Enmove anticipates that the development of this next-generation refrigerant will allow for a swift response to reinforced global greenhouse gas emission regulations and secure a leading position in the market. Furthermore, in collaboration with the Energy Saving R&D Center at SK Innovation Institute of Environmental Science & Technology, SK Enmove aims to expand its business into various sectors, such as home appliances and buildings, by accelerating development efforts to solidify its status as an “Energy Saving Company.”

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin