SK Geo Centric

SK Geo Centric■ Marks the next phase in the commercialization of infinite Loop™ facilities across Asia

■ Breaking ground of first facility in Ulsan, South Korea, anticipated later in 2023

Montreal (Canada) – SK Geo Centric (SKGC) and Loop Industries (Loop), a clean technology company whose mission is to accelerate a circular plastics economy by manufacturing 100% recycled polyethylene terephthalate (PET) plastic and polyester fiber, today announced the successful completion of a technical due diligence conducted by SKGC and the validation of Loop’s technology. The technical due diligence marks the next phase in SKGC and Loop’s long-standing partnership to commercialize Loop’s technology through Infinite Loop™ manufacturing facilities in the Asian market.

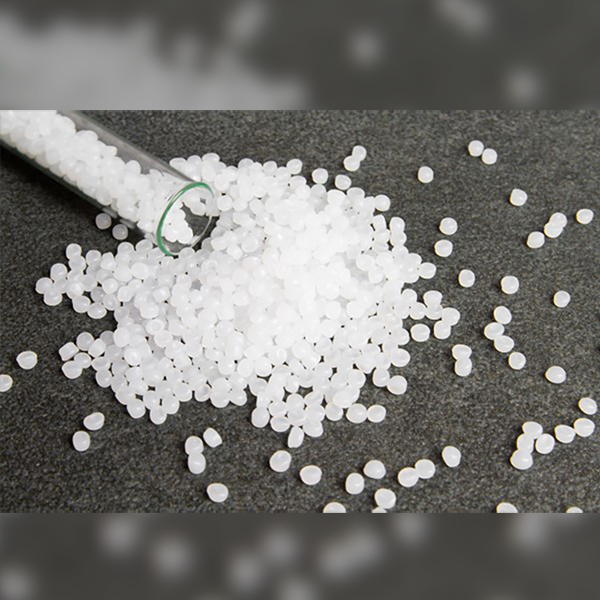

SKGC, which acquired a 10% equity stake in Loop in August 2021, executed a comprehensive due diligence to validate Loop’s technology and its production facility in Terrebonne, Quebec. The scope of the technical due diligence included the depolymerization of low value PET waste into its base monomers of DMT and MEG, the purification of the monomers, as well as the polymerization into virgin-quality Loop™ PET resin and polyester fiber. Key parameters of Loop’s technology that were validated were the production yields, operational stability, quality of the outputting monomers and overall performance of the production facility. The technical due diligence validated that the PET resin and polyester fiber produced using Loop’s technology is of virgin-quality. The technical due diligence report, signed by both parties, confirms Loop’s innovative technology.

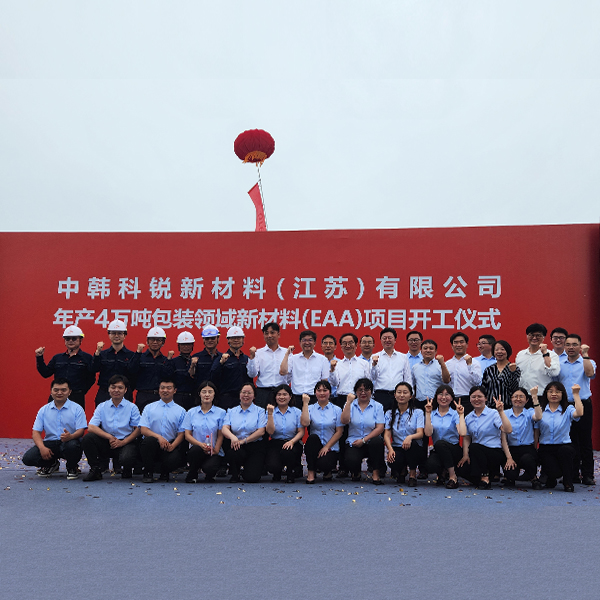

SKGC and Loop are committed to commercialize the Infinite Loop technology in Asia and the partners are planning several jointly built large-scale manufacturing facilities. SKGC and Loop are also working together with SK ecoengineering (SKEE), a subsidiary of the SK Group who brings considerable experience and proficiency as an EPC contractor, on the engineering services for their Asian manufacturing facilities. The first Asian manufacturing facility in Ulsan, South Korea, is anticipated to break ground in 2023 and the evaluation of the second Asian facility has already begun. The next step in the partnership is to sign the definitive joint venture agreement which is currently being finalized.

“We are confident that Loop Industries’ cutting-edge technology of PET recycling will be a winning tech in the industry. We are currently focused on the planning of our first manufacturing facility in Ulsan, South Korea, where we will implement Loop’s technology”, said Ham Hyeong-taek, Chief Technology Officer of SK Geo Centric.

“SK Geo Centric has closely studied Loop’s technology that depolymerizes PET waste. With our combined efforts, we aim to utilize and increase the use of a more diversified selection of PET feedstock which will drive circularity for this material,” Leader of Environmental R&D center of SK Innovation Kim Tae-jin added.

“The technical due diligence, executed by SKGC’s extremely knowledgeable group of scientists and engineers at our production facility in Terrebonne, has further validated the effectiveness and robustness of our technology. This complete due diligence is a critical milestone to our partnership with SKGC and the commercialization of Infinite Loop™ manufacturing plants across Asia. Due to the large population centers and being the main hub for the polyester fiber supply chain for textiles, the Asian market represents a tremendous opportunity for growth,” said Loop Founder and CEO Daniel Solomita. “We are delighted to continue working closely with SKGC and to commercialize our technology in the Asian market.”

“The successful completion of this technical due diligence validates our unique process and reaffirms the overall performance of our production facility,” said Vice President of Science and Innovation for Loop Industries Adel Essaddam. “Our technology enables us to make virgin-quality Loop™ PET resin and polyester fiber from low-value PET plastic, which is an important step towards our goal of reducing plastic waste and becoming a leader in PET plastic circularity.”

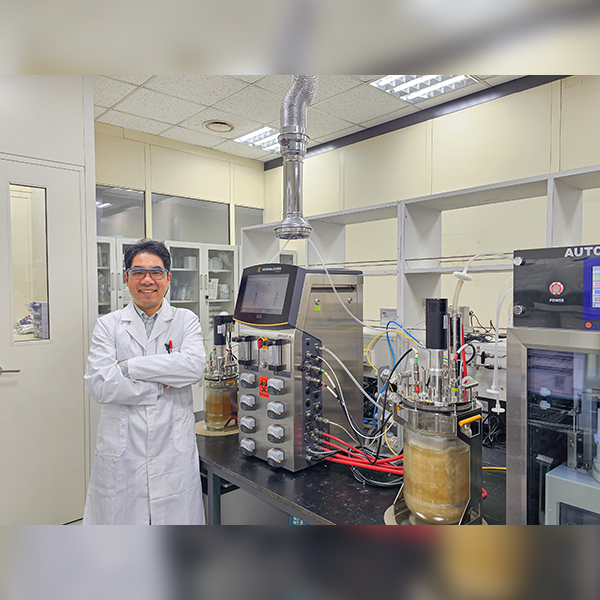

[Photo]

Loop Industry’s production facility in Terrebonne, Quebec, Canada

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin