SK Geo Centric

SK Geo Centric■ SKGC engineers and researchers visited PCT’s Ohio plant and completed more than 1,000 hours of technical consultations.

■ Sets adjustment and construction plan to optimize the recycling process for Korean waste plastic feedstock

■ Kim Jong-hwa, Chief Strategy Officer of SKGC: “We will successfully build Ulsan ARC by strengthening partnerships between the two companies to realize circular economy”

On March 10 (KST), SK Geo Centric (SKGC) has completed technical consultations necessary for the creation of Ulsan ARC (Advanced Recycling Cluster), the world’s first plastic recycling complex to be built by 2025.

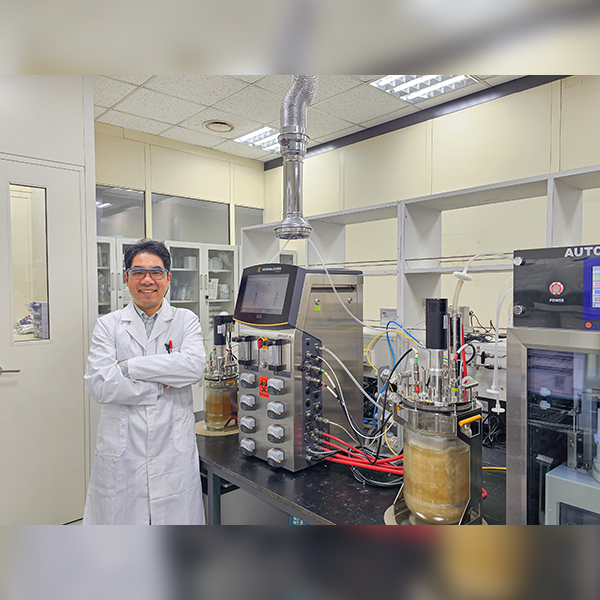

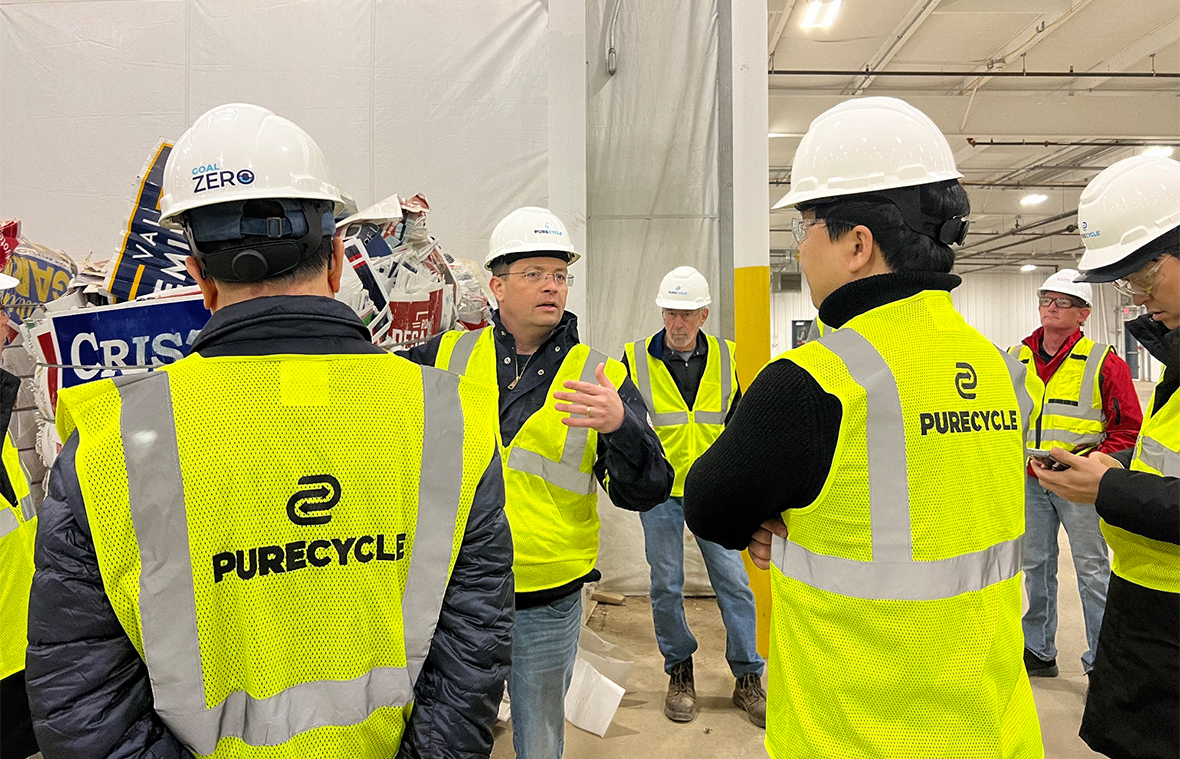

Over the last two months, 12 engineers and researchers of SKGC visited PureCycle Technologies (PCT)’s polypropylene (PP) recycling plant in Ironton, Ohio, the U.S. and completed facility adjustments and technical consultations with PCT to optimize the recycling process.

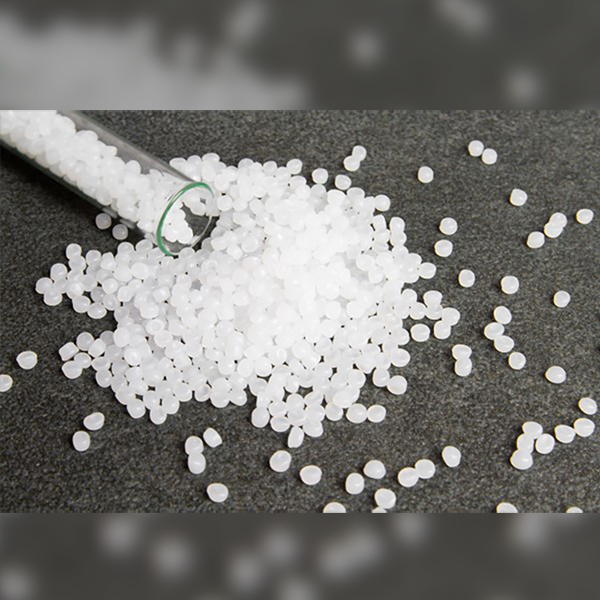

SKGC’s global partner PCT is an advanced recycling company that utilizes solvents to remove nearly all contaminants, colors and odors from polypropylene plastic waste (No. 5 plastic), altering it into an ultra-pure recycled reusable resin. PCT and SKGC signed a joint venture contract in October 2022.

At PCT’s Ironton plant, which is expected to produce about 60,000 tons of recycled plastic per year, engineers from both companies held over 1,000 hours of online technical discussions and face-to-face meetings since January of this year. Since waste plastics differ in properties and purity from country to country, it was necessary to alter the process designs to be optimized for those discarded in Korea. The two companies decided to put waste plastic (feedstock) into the recycling process through various tests, including recycled polypropylene extraction, to optimize it for Korean feedstock.

Construction of PCT’s purification plant is designed for modularization and can be applied at the Ulsan recycling complex. Compared to the method of clearing a site location and building up the construction frame sequentially, this process can shorten the construction timespan by composing modules during each construction stage and combining them later at the site.

The two companies plan to begin construction in Ulsan by the end of this year and start commercial production by 2026. SKGC holds exclusive sales rights in Korea and has secured business rights priority in China and major Southeast Asian countries. The company is looking forward to not only realizing Ulsan ARC, but also expanding its global business overall.

Dustin Olson, CEO of PCT, said, “Our teams have spent the past two years working together to build a path forward for growth in Asia. This week was another milestone moment toward delivering this technology to South Korea.”

“Through this cooperation, the two companies have enhanced their understanding of technology and optimized the recycling process plan to suit the nature of waste plastics in Korea,” said Kim Jong-hwa, CSO of SKGC.

[Photos]

(Photo 1) PureCycle Technology (PCT) CEO Dustin Olsen is discussing with PCT and SK Geo Centric members during a technical consultation held at PCT’s Ohio Plant in the United States.

(Photo 2) PCT CEO Dustin Olsen explains the recycling process of waste plastics that will be put into chemical recycling technology that extracts Ultra Pure Recycled PP.

(Photo 3, 4) SK Geo Centric and PCT engineers and researchers who participated in the technical consultation between the two companies at PCT’s Ohio Plant in the United States

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin