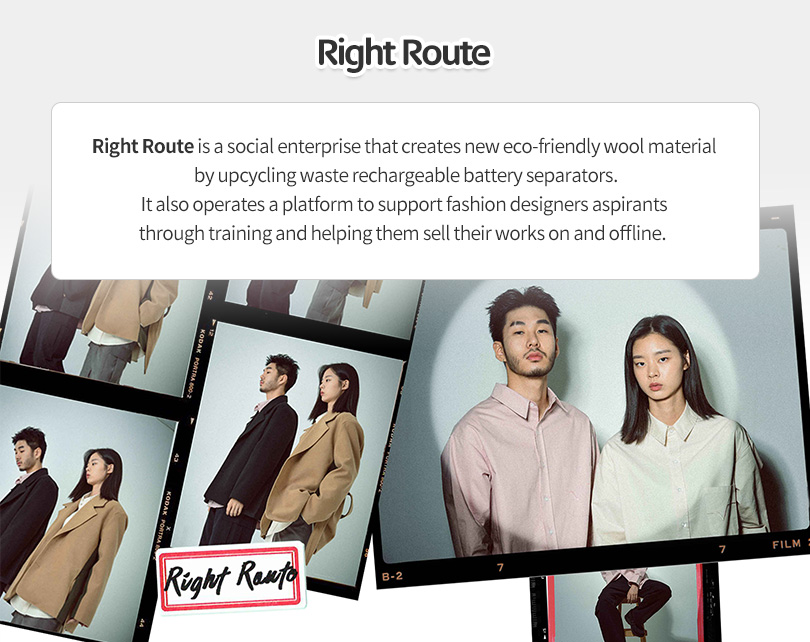

Social Enterprise

Social Enterprise

An interview with Shin Min-jeong, CEO of Right Route,

one of the three winners of the Environmental Social Business Discovery Contest

selected by SK Innovation in 2020.

Right Route’s homepage: https://rightroute.kr/

Q1. First of all, could you share with us the story about how Right Route was established?

In 2015, I started a fashion designer training incubator business. While making clothes with fashion designers, I learn more about the fashion industry waste and became interested in this problem. So in 2016, we started a surplus fabric project to make clothes using surplus fabric that was supposed to be disposed. About three years later, I heard from a CEO of a firm that produces secondary cell separator film that they are also having surplus film after production, while this material is as highly functional as Gore-Tex. After learning about it, I realized that we could create an even bigger social impact than the existing surplus fabric project, so I decided to expand our business to high-function material using surplus Lithium ion battery separation film.

Q2. We would like to know more about the upcycling technology you have and how you make clothes from the EV battery separators.

Right Route’s new material, the upcycled high-performance wool, is created base on the similar cross-sectional structures between the battery separators and Gore-Tex, which has features such as being breathable (from the inside) and waterproof (from the outside). There are countless invisible pores in the separator membrane, which are smaller than droplets but larger than water vapor molecules. By attaching the battery separators and wool material with an eco-friendly adhesive, Right Route can improve the moisture permeability and waterproof properties that battery separators have but natural wool do not, while making use of the soft touch that natural wool can provide to create a new, better material. This is how Right Route upcycles the discarded separators to make it become a useful product with environmental value.

It may sound simple but to make all that possible, I visited numerous chemical factories and research institutes to find adhesives that do not block the fine holes in the separator, ways to make each fabric material well attached to the separator. I also had to find the proper temperature and level of pressure that do not harden the separator film. It was not easy, but I’m glad that we’ve found a solution to help us make another step forward on our way to create a sustainable fashion industry.

▲(Left) The production method of Right Route to create new material from upcycling discarded battery separators/ (Right) Upcycling high-performance wool new material made by Right Route

Q3. Battery separator film is not a material commonly used in fashion, so is it safe to our skin? And how about the cost?

Yes, it is safe to wear. Our product was tested for toxicity. Started from lead to numerous harmful substances, we analyzed all of them and the result was good. There was no problem so you can wear clothes made from this new material without worries. It explains that harmful substances (volatile components) in the separator were removed during manufacturing process.

Regarding the manufacturing cost, high-performance fabrics using upcycled battery separator have lower price than Gore-Tex. Battery separator manufactures have to spend a certain cost to dispose the remaining materials and it is not easy to recycle the separators. Therefore, we can get raw materials from them with low price while providing a solution to reduce the amount of industrial waste. In other words, this is how we create economic value and social value at the same time.

Q4. As a social enterprise, we heard that Right Route is not only making eco-friendly clothes but also having a platform to support young designers. Please tell us more about this platform.

Yes, we are providing a platform for aspiring fashion designers to have chances to not only show their designs, but also sell their works. The designer aspirants, selected by Right Route will be trained with our support in three months. When their designs can be made into real clothes, Right Route will help them sell their works in both online and offline markets. In addition, the profits generated by those products will be shared with trainees, and a portion will be used for the next trainees.

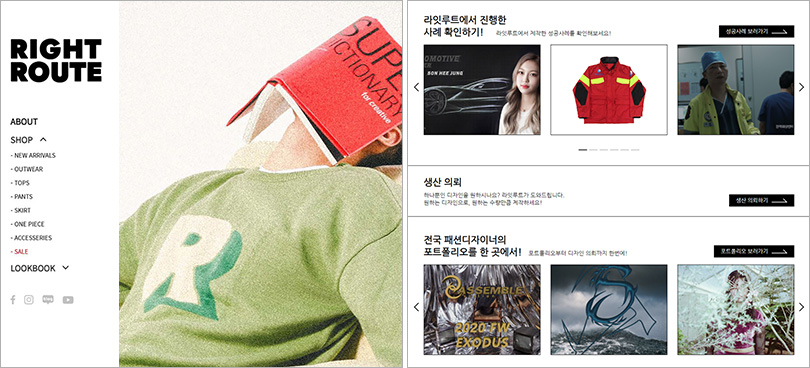

▲ Right Route’s official website (https://rightroute.co.kr/) / (Right) Designer training platform operated by Right Route (https://www.rightroutebridge.com/)

Q5. Last year Right Route was among the winners of the Environmental Social Business Discovery Contest selected by SK Innovation. After the Contest in November, how are you preparing for your next moves?

We have completed the development of materials using surplus battery separation film by the 4th phase. We are checking the possibility of mass production and planning to make it available in the market soon after our product patent is issued this year. Also, we are preparing for the official launch of Right Route Bridge, a crowd sourcing platform that connects fashion designers and clients.

In the long run, we intend to grow into a global upcycling material brand by supplying our own materials to overseas markets, starting with Europe. Our growth direction is to develop high-performance upcycled materials to solve environmental issues, and to strengthen competitiveness by focusing on the functions (durability) of our product to deliver the best value to customers. We will try our best to make Right Route a company that spreads the slow fashion culture and presents the right path for the fashion industry by developing materials that can be worn for generations with solid craftsmanship.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin