Sustainability

Sustainability

Jeon Young-ill (left) and Ahn Seong-bok (right), Members of the SHE Tech Unit at SK Enterm

Ulsan, the industrial heart of South Korea, is home to SK Innovation’s Ulsan Complex (hereafter referred to as Ulsan CLX). Ulsan CLX, located within Ulsan Port and operating a total of 8 docks, is at the forefront of establishing a “Safety First” corporate culture, implementing top-tier safety management practices. Over the past two years, SK Enterm spearheaded a company-wide efforts to establish a port’s safety and health system, redesigning all aspects concerning the S·H·E* concept, from facilities improvement to safety training and risk assessment.

*S·H·E is an abbreviation for Safety, Health, and Environment.

SK Enterm undertook these changes for two reasons. Firstly, due to the enforcement of the Special Act on Port Safety** in August 2022. Secondly, because of the value of life itself. Considering that the rate of accidents and fatalities at sea and port facilities is higher than in other industries, incidents resulting in minor injuries on land can lead to fatal outcomes at sea. To address this issue, SK Enterm introduced a project called “Creating a Safe Maritime Work Environment at Ulsan CLX,” with the goal of achieving “Zero human accidents.” We discussed these efforts with Jeon Young-ill and Ahn Seong-bok of S·H·E Tech Unit at SK Enterm. Both are Maritime Safety Officers responsible for establishing and operating safety management standards for marine facilities, managing safety for coastal and import/export vessels, and handling cooperation projects and external affairs related to marine and port activities.

**Special Act on Port Safety: A special law enacted on August 3, 2021, and implemented from August 2022 to prevent port safety accidents. A key aspect of this law is the introduction of a Port Safety Inspection Officer, a role that reflects the unique environment of ports and the need for tailored safety management strategies. These officers are responsible for verifying the implementation of safety plans at workplaces.

| History of Ulsan CLX’s port safety and health system (2022-2023)

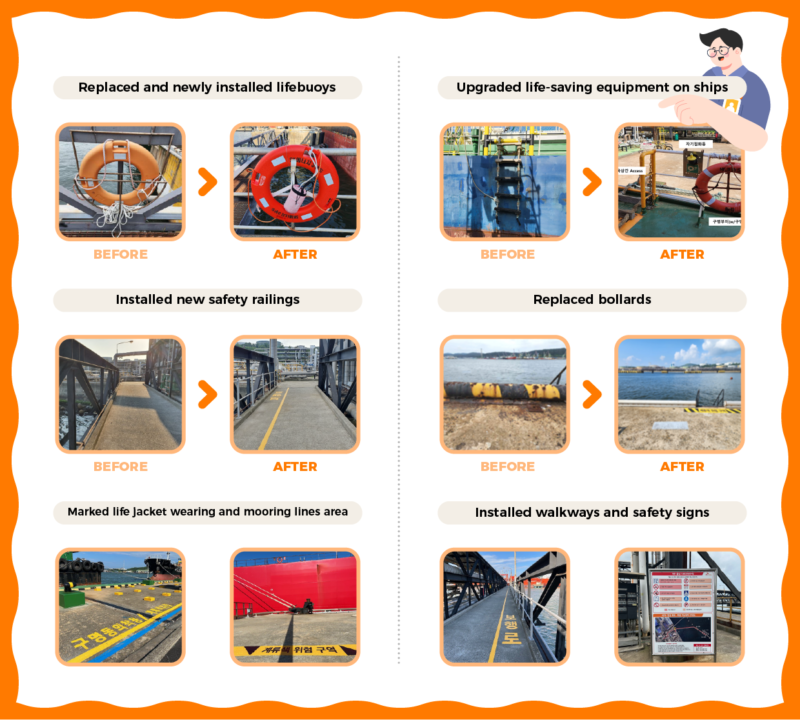

① Hazard elimination at workplace

Based on field inspections, outdated and high-risk facilities were removed and replaced. Improvements were made across all areas, from SK’s docks to the interiors of vessels.

② Comprehensive safety training for port facility and coastal vessel workers

he previous generalized safety guidelines have been refined to cater specifically to the duties of cargo supervisors and inspectors, resulting in more detailed and user-friendly training materials. As of 2023, annual safety training is mandatory for all operators at Ulsan CLX SK docks.

③ Enhancing risk assessment and reducing human error

A comprehensive review of the existing Job Risk Analysis (JRA) for crude oil unloading operations has resulted in an overhaul of the risk assessment system. For tasks rated at risk level 5 and above, Job Safety Analysis (JSA) has been conducted, and new facilities have been installed to structurally prevent human errors and mitigate risks.

④ Strengthening worker-led S·H·E activities

Workers stationed on buoys*** and regular patrol vessels face unique challenges due to the lack of constant supervision, unlike their land-based counterparts. To address this, SK Enterm has implemented a partner-led S·H·E activity program to ensure seamless safety management.

***Buoy: a maritime facility primarily used by Very Large Crude-Oil Carriers (VLCCs), which are difficult to dock. Crude oil is transported from these buoys to onshore storage tanks via underwater pipelines.

| Leading port safety: Members of the SHE Tech Unit at SK Enterm, Jeon Young-ill and Ahn Seong-bok

Q1. “Creating a Safe Maritime Work Environment at Ulsan CLX” project involved improving marine facilities, safety training, and risk assessment. How do you feel about completing this project?

If there’s a problem with the facilities, we can fix it, but if someone gets hurt, it can’t be undone. We approached our work with the determination that “No human accidents should occur at our dock.” Though site inspections and case studies took more time than we expected, in hindsight, it was time well spent. We made a point to actively listen to the concerns of both our team members and our partners. As a result, we made practical improvements aimed at genuinely preventing accidents, not just ticking boxes. That accomplishment feels particularly rewarding.

If Jeon’s standard was the site, mine was Jeon Young-ill himself. I joined the “Creating a Safe Marine Working Environment at Ulsan CLX” project last year, and it was a whirlwind. Thankfully, I had a guiding light to help me navigate safely – it’s him, Jeon Young-ill.

Q2. You can clearly see the difference in the before-and-after photos. What aspects did you focus on for these improvements?

When the dock ages, it inevitably leads to structural problems. Issues like corrosion are bound to occur, and breakdown intervals become increasingly shorter. However, completely replacing the facilities with new ones isn’t realistically feasible. So, we put a lot of thought into what needed replacing and how we could best maintain and repair the existing structures. In this process, the insights and opinions of the on-site team members were incredibly valuable.

Q3. Can each of you share one improvement you’re particularly proud of?

For me, it would be the installation of non-slip footplates and painting at the crude oil buoy access route. Accidents at sea and ports have a high risk of turning fatal. Even minor incidents like falling or getting caught can escalate into major accidents. We implemented this to prevent even small accidents, and it was highly praised by the site members.

For me, it would be the installation of non-slip footplates and painting at the crude oil buoy access route. Accidents at sea and ports have a high risk of turning fatal. Even minor incidents like falling or getting caught can escalate into major accidents. We implemented this to prevent even small accidents, and it was highly praised by the site members.

In my case, it would be safety signs. They might seem small, but their impact is significant. There’s no better way to remind people of essential safety rules than through the visible and clear safety signs.

Q4. It has been mentioned that safety training has changed significantly. What prompted these changes?

Safety training is now conducted on two tracks. One for port facility workers, and the other one for regular training of coastal vessel crew members. The most significant changes have been made in the training for port facility workers. We’ve moved away from the old method of teaching a unified set of guidelines and instead, we developed guidelines customized to specific job roles. Now, mooring handlers, cargo supervisors, inspectors, and agents receive safety training that correspond with their responsibilities. The key is not just having guidelines but ensuring proper ‘implementation.’

We also extended training to the personnel from related organizations such as the maritime police, fire department, and port authority—not just for facility workers. In the event of accident on a tanker, firefighting and rescue operations differ from those conducted for regular ships. Therefore, we provided opportunities for these teams to get hands-on experience by boarding tankers, and help them familiarize with the structure, firefighting equipment, and life-saving gear.

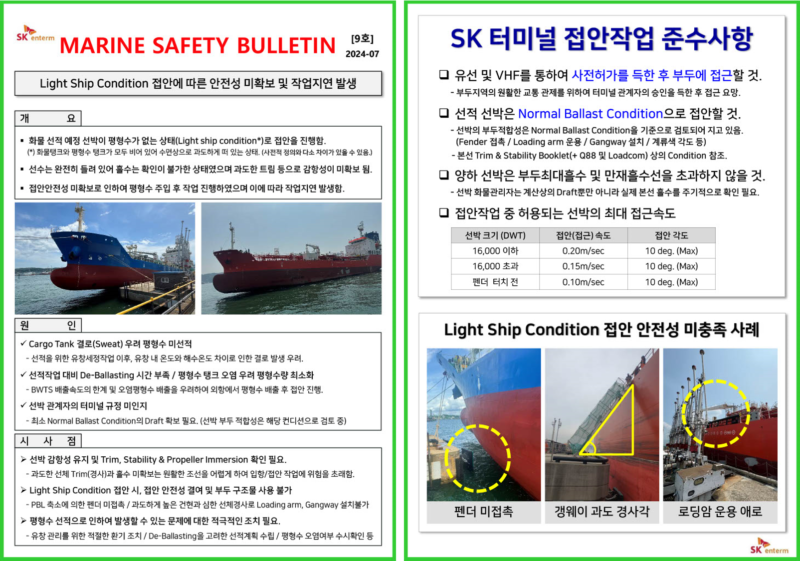

Q5. You are currently publishing the “Marine Safety Bulletin.” What was the idea behind the newsletter aimed at port and coastal vessel operators?

It’s great to have a newsletter dedicated to the staff working at the SK docks. Ahn brought a fresh perspective to the planning after joining us!

One thing I noticed during my ten years while working at sea is that people don’t have much time to read. That’s why we chose a magazine format. We thought that a safety newsletter featuring visuals would capture their interest. We focused on accident cases to increase engagement and organized it in an easy-to-read way. The response procedures can be found on a single page, making sure it’s read all the way through. We’ve published nine issues so far and are committed to making the ‘Marine Safety Bulletin’ a must-read for our audience.

Marine Safety Bulletin Issue 9, published in July 2024

Q6. Do you have anything you wish to say before we end this interview?

First, I want to thank all the team members who supported us throughout this project. It wouldn’t be an exaggeration to say that our SK Enterm Operation Office is both the “beginning” and the “end” of Ulsan CLX. I’m proud to be a part of this team, and together with all the members of Ulsan CLX, we will continue to fulfill our responsibilities in our respective roles for a better tomorrow.

As a Maritime Safety Officer at Ulsan CLX, I’m proud to contribute to creating a reliable marine working environment. I will always do my best to maintain accident-free SK docks.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin