Social Enterprise

Social Enterprise

Morethan, a social enterprise supported by SK Innovation, has opened an ecological factory to celebrate World Environment Day on the 5th.

Being famous for its upcycling brand Continew, Morethan uses discarded car seat leather, airbags, safety belts, etc. to recycle and re-design them into new fashion products including bags, wallets, shoes, and accessories.

Morethan’s ecological factory is located at Paju, Gyeonggi-do, South Korea. It is called an ecological factory since the whole manufacturing process of all products here is operated in an eco-friendly manner. From how Moreathan secures the raw materials to water and electricity required for production, every step is taken in the most possible eco-friendly method.

▲ Morethan’s ecological factory is located at Paju, Gyeonggi-do, South Korea

Morethan can provide natural leather products without slaughtering livestock by using scrap leather that is thrown away during the manufacturing process of automobiles. The ecological factory has also achieved zero water footprint. The water that is needed to wash scrap leather is rainwater. The wastewater generated after washing is then filtered and recycled to be used as washing water, again. This water system is the result of Morethan’s 14 months of developing. The water saving effect obtained through this upcycling system is estimated to be about 110,000 tons per year.

▲ Water circulation system in Morethan’s ecological factory

The electricity in this ecological factory is green energy eco-friendly as wells since it is obtained through the solar panels installed on the roof of the factory. Furthermore, Morethan plans to become an eco-friendly power supplier by producing excessively about 50% of the power required in the ecological factory later this year, increasing the social value it can create.

▲ Solar panels installed on the roof of Morethan’s ecological factory

So far, Morethan is said to be the first manufacturer in global fashion industry that operates a factory with 100% self-supplied water and electricity. Furthermore, the interior of Morethan’s ecological factory is made from waste materials and hardwood floors of abandoned schools, with shelves made from pressed sawdust, chairs made from leftover tree branches, etc. All products packaging boxes and shopping bags also use 100% recycled paper and eco-friendly ink. In short, the ecology factory embodies Morethan’s great efforts to reduce carbon footprint at every stage, from factory facilities to raw materials, production, and packaging.

The ecological factory is open to anyone who wishes to visit and share the same interest with Morethan.

▲ A closer look inside Morethan’s ecological factory

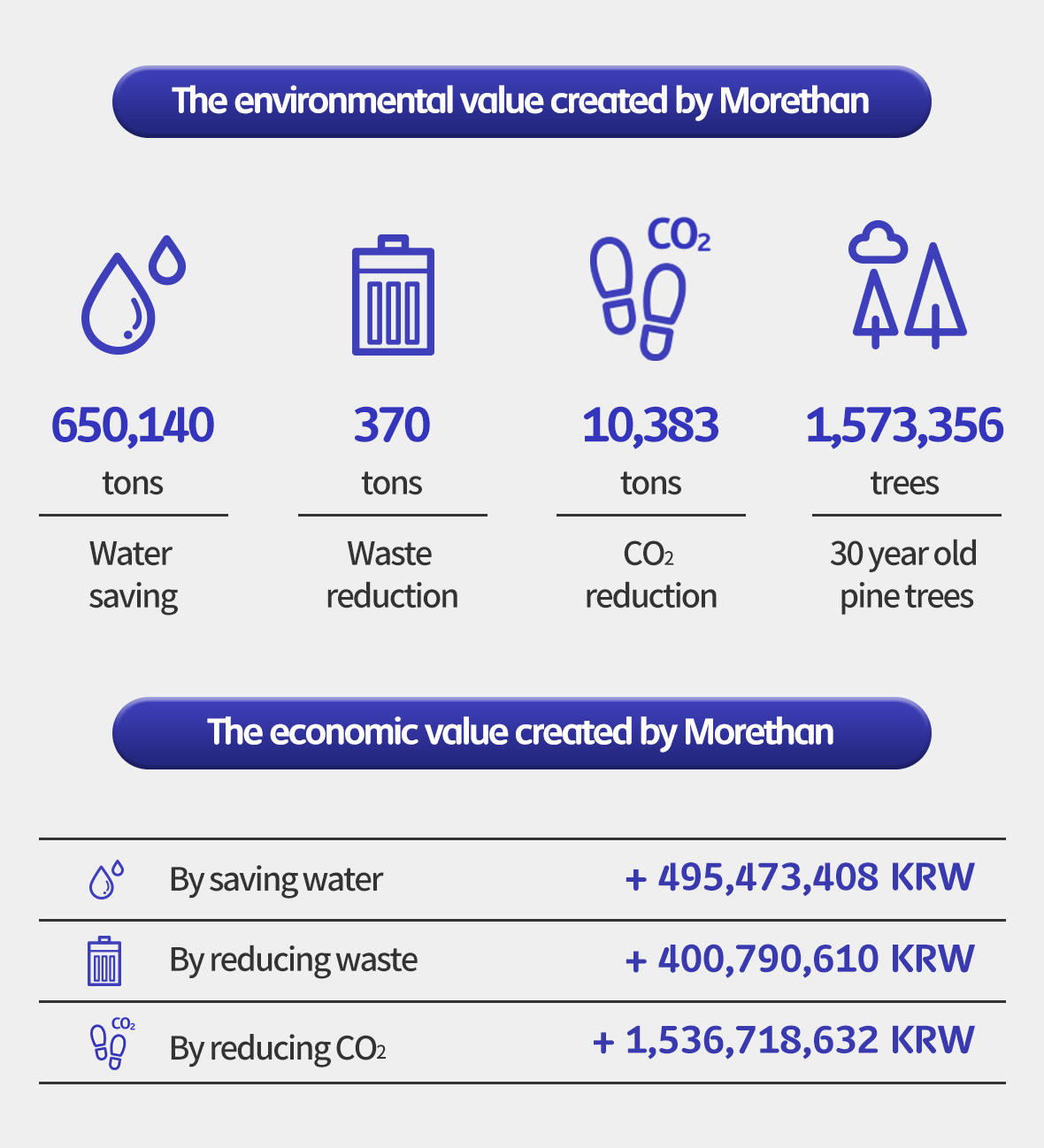

*Data measured from Morethan’s establishment in 2015 to May 13th 2021.

*Data measured from Morethan’s establishment in 2015 to May 13th 2021.

Founded in 2015, Morethan has saved total 650,000 tons of water and recycled 370 tons of waste so far. As a result, 10,000 tons of carbon dioxide have been reduced, creating the same environmental value as planting 1.58 million 30-year-old pine trees.

Before the official open of its ecological factory, Morethan was selected as a Baby Unicorn of “Baby Unicorn 2020 Fostering Project*’ hosted by the Korean Ministry of SMEs and Startups and the Korea Institute of Startup & Entrepreneurship Development (KISED) on May 26th. Morethan is the only social enterprise among 60 companies selected this time. Through this, Morethan was once again recognized for its excellent ESG business model and future growth potential to succeed in the global market.

(*) Baby Unicorn 2020 Fostering Project: As the first phase of the K-Unicorn project to realize the four major venture powerhouses, the purpose of this project is to discover companies with global competitiveness and growth potential and foster them as K-Unicorn companies.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin